Related posting of Output And Consumption in Production Journal

REQUIREMENT / BUSINESS VALUE

Related posting of Output and Consumption in Production Journal functionality enables calculation of related quantities in Production.

Functionality brings two ways of calculation:

- Calculate Output quantity based on entered Consumption quantity of main product ingredient. When Consumption Quantity is entered to Production Journal, Output quantity is automatically calculated based on the BOM structure (Output is Sum of Consumption).

- Calculate Consumption based on entered Output and Scrap quantity. Consumption Quantity is automatically suggested for all materials and semifinished products based on BOM structure.

Functionality improves user experience. Production Journal is used when user wants to post Consumption and Output at the same time. Automatically suggested quantities can significantly reduce time required to enter all required parameters into Production Journal. After quantities are automatically suggested, user can manually adjust suggested quantities.

NOT supported is:

1. Consideration of scrap quantity

2. Automatic adjustment of item tracking quantity

Setup

Functionality can be enabled by definition of some parameters in Manucacturing Setup and on Items used in Production Journals.

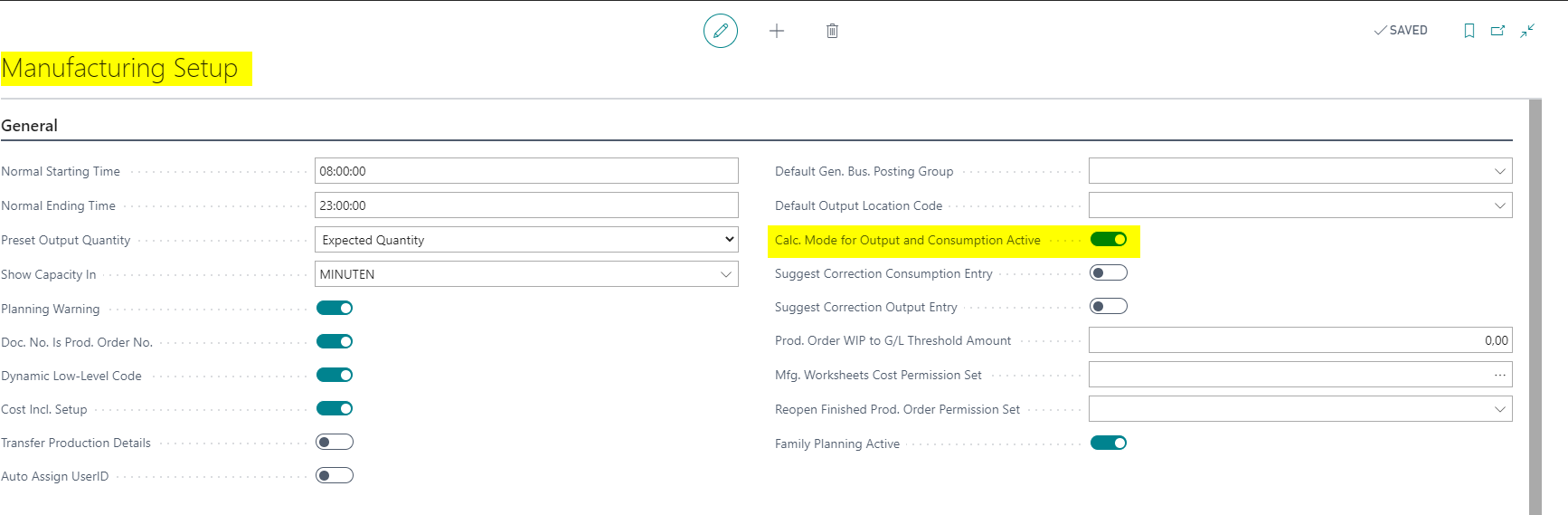

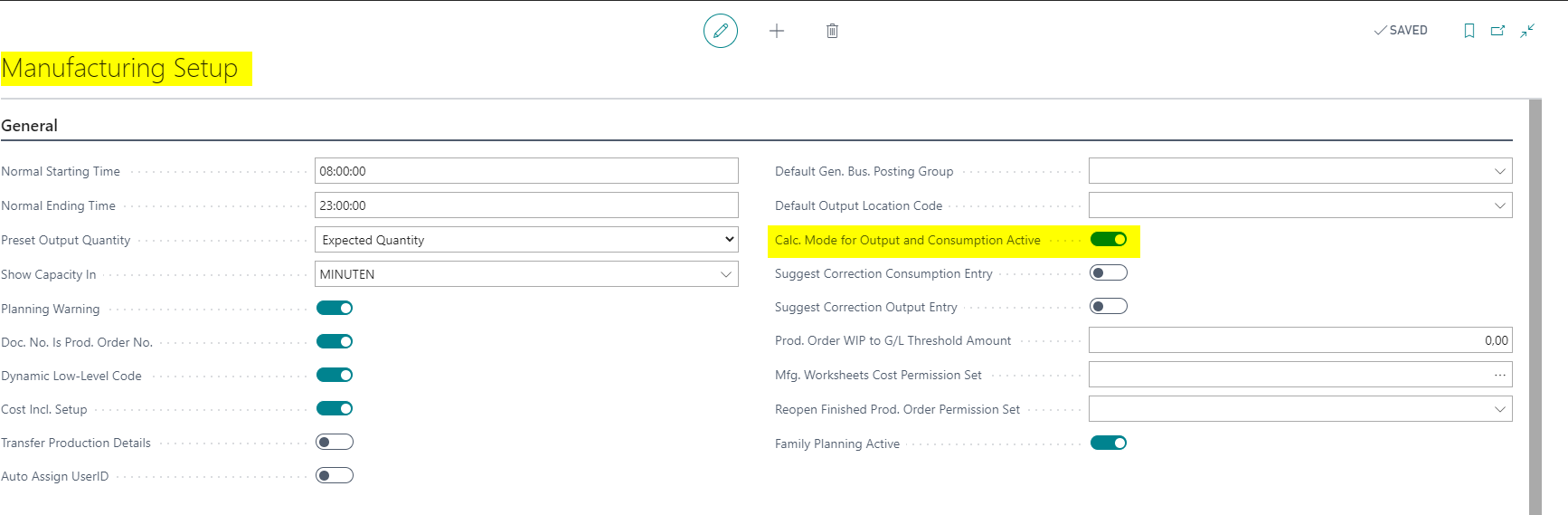

Manufacturing Setup

- Open Manufacturing Setup.

- Set field "Calc. Mode for Consumption and Output Active" on General FastTab to enable functionality.

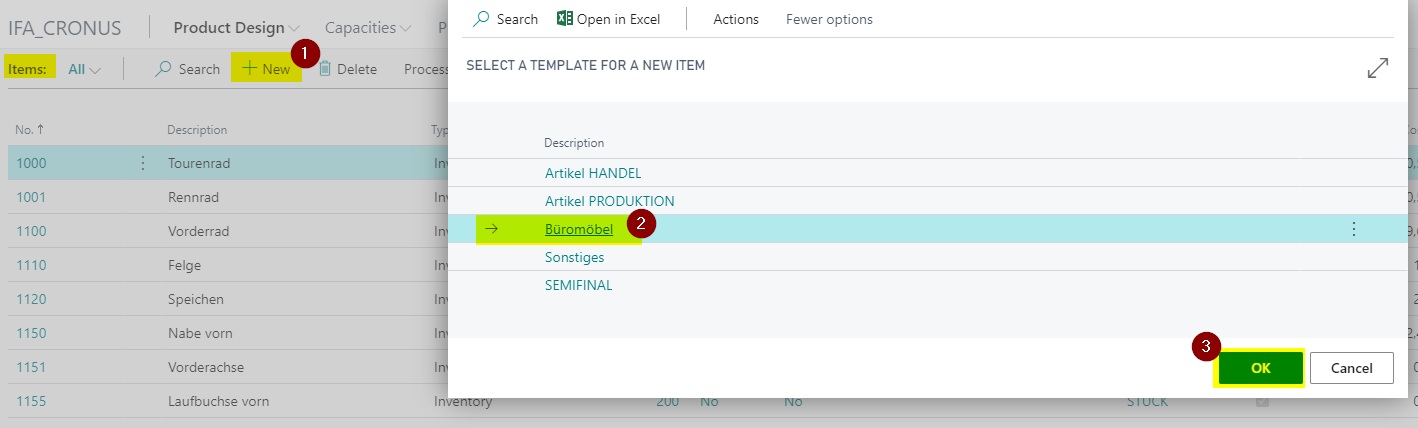

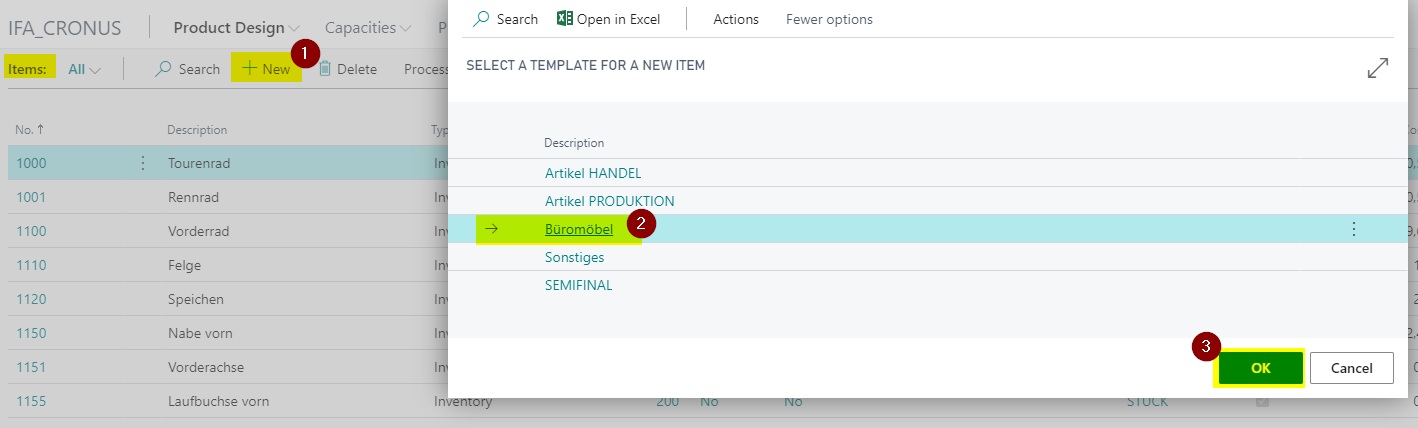

Item

- Open Item List and create a new Item by choosing button New on Home Tab.

- Select pre-prepared Item Template.

Item Template can have preset value also for fields "Production Journal - Calculation Mode for Output and Consumption" and "Is Output Sum of Consumption".

NOTE: Values can't be selected in Confuguration Template when prepared, but need to be manually entered.

-

Enter Item parameters.

-

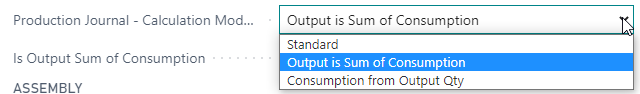

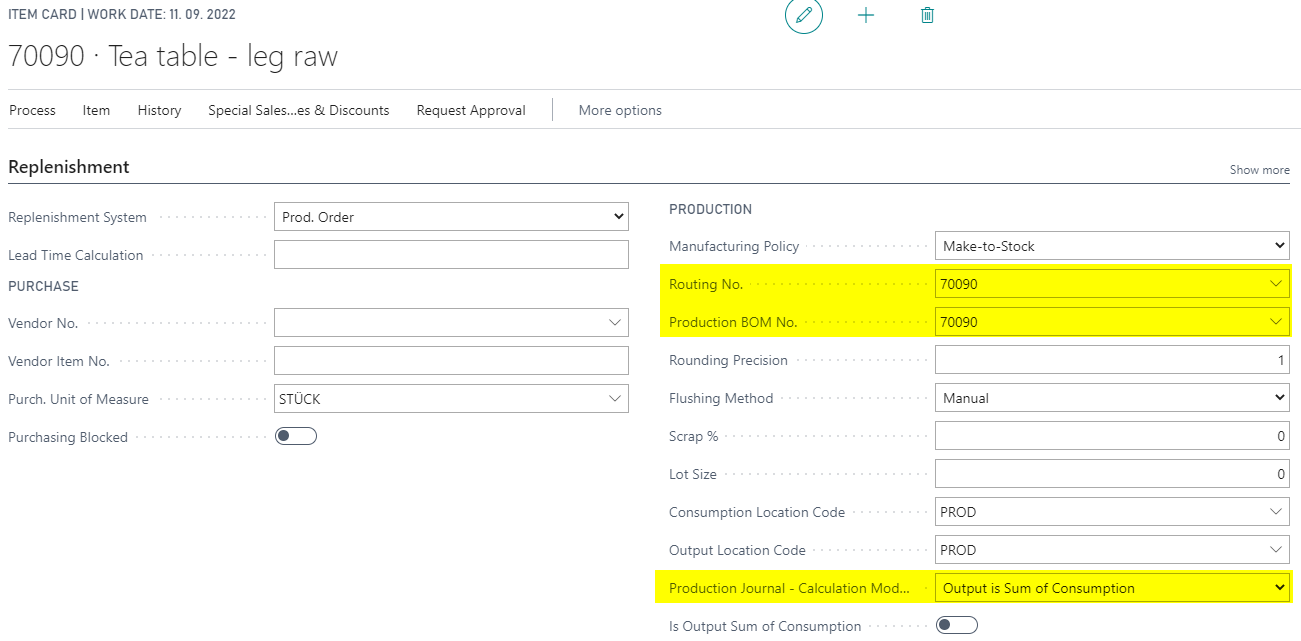

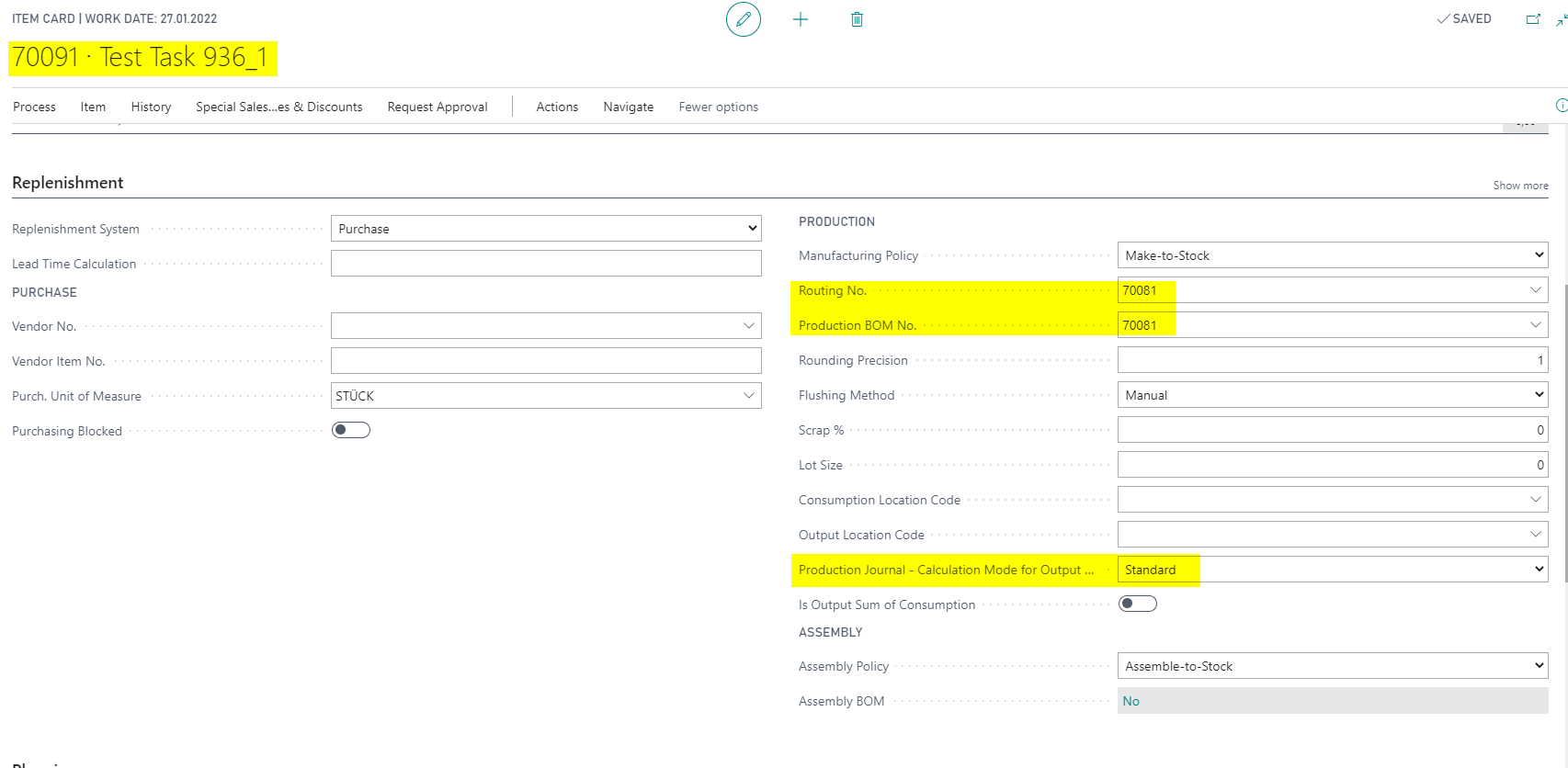

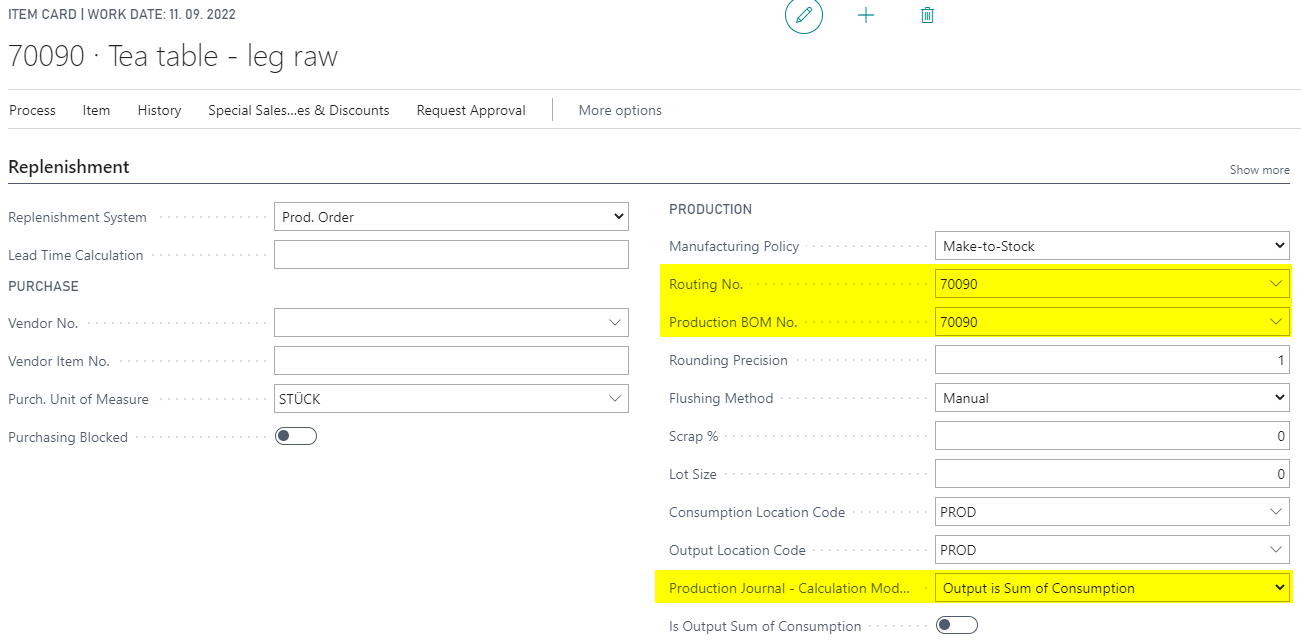

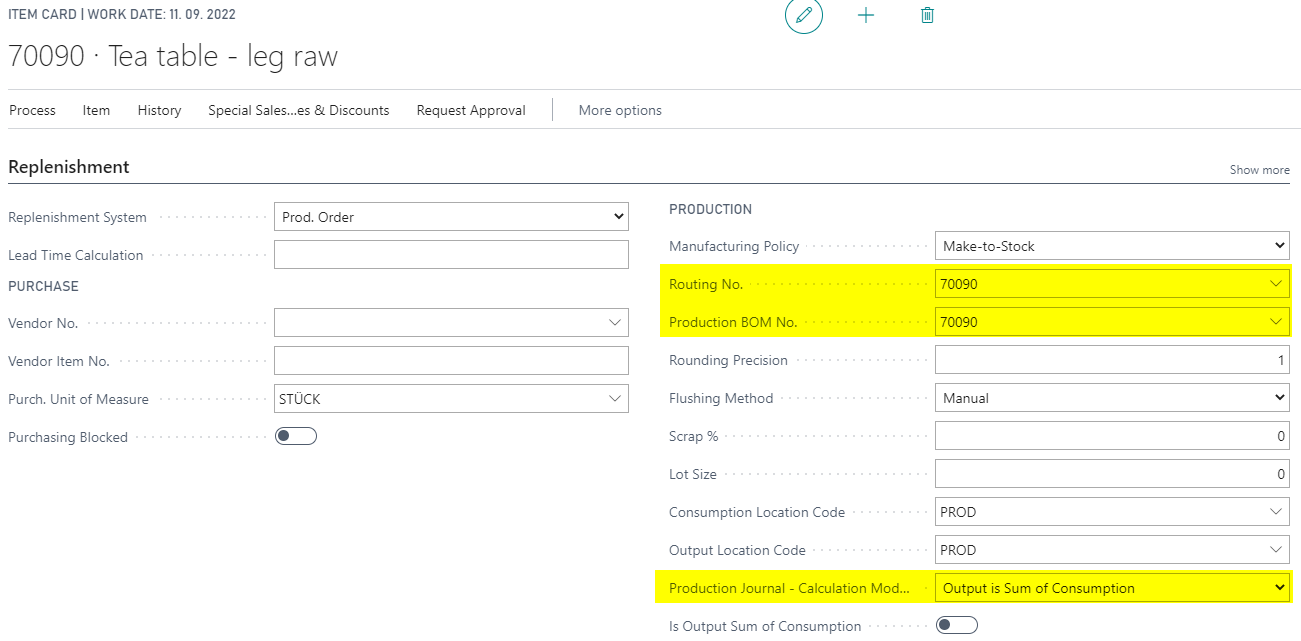

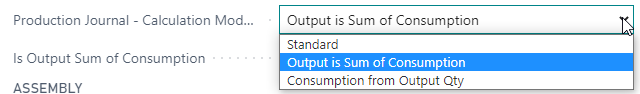

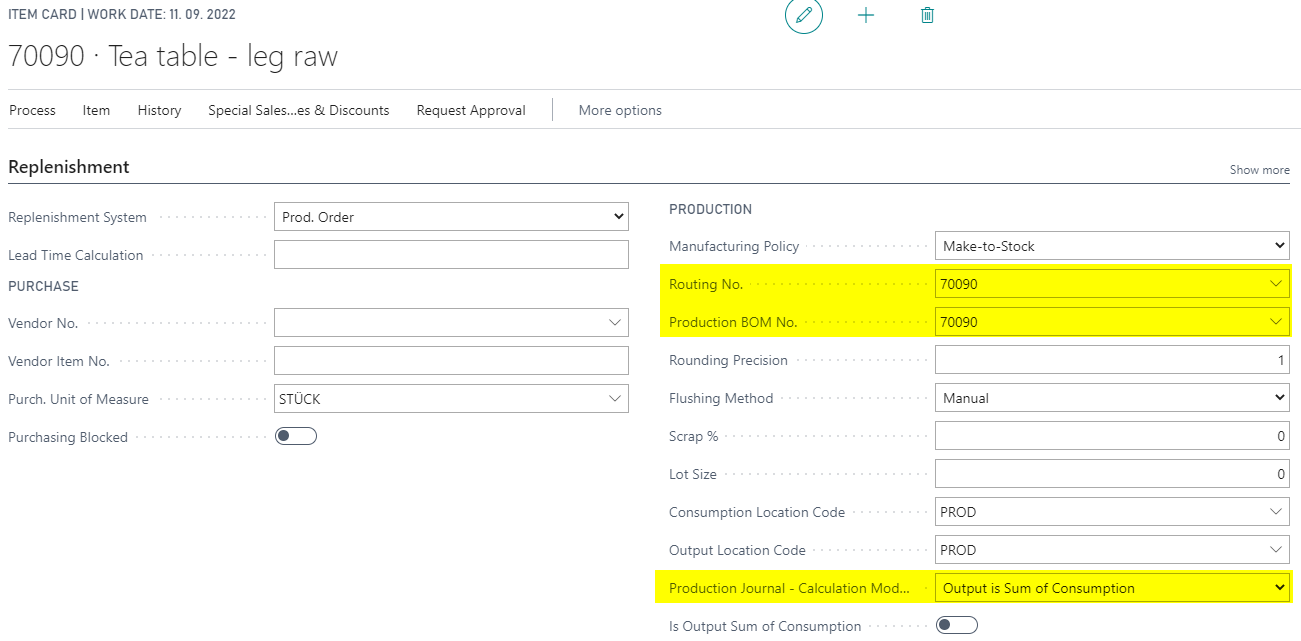

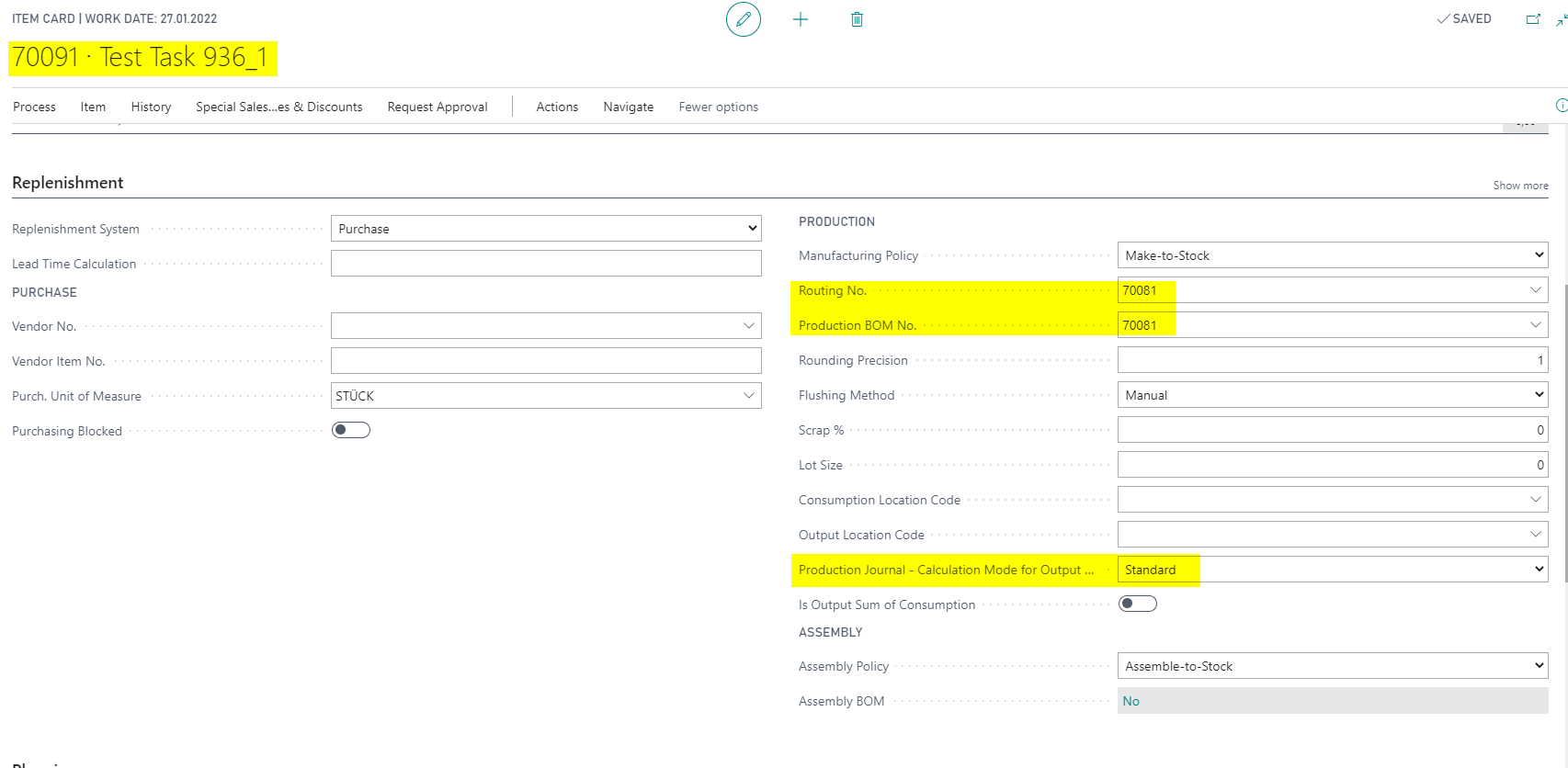

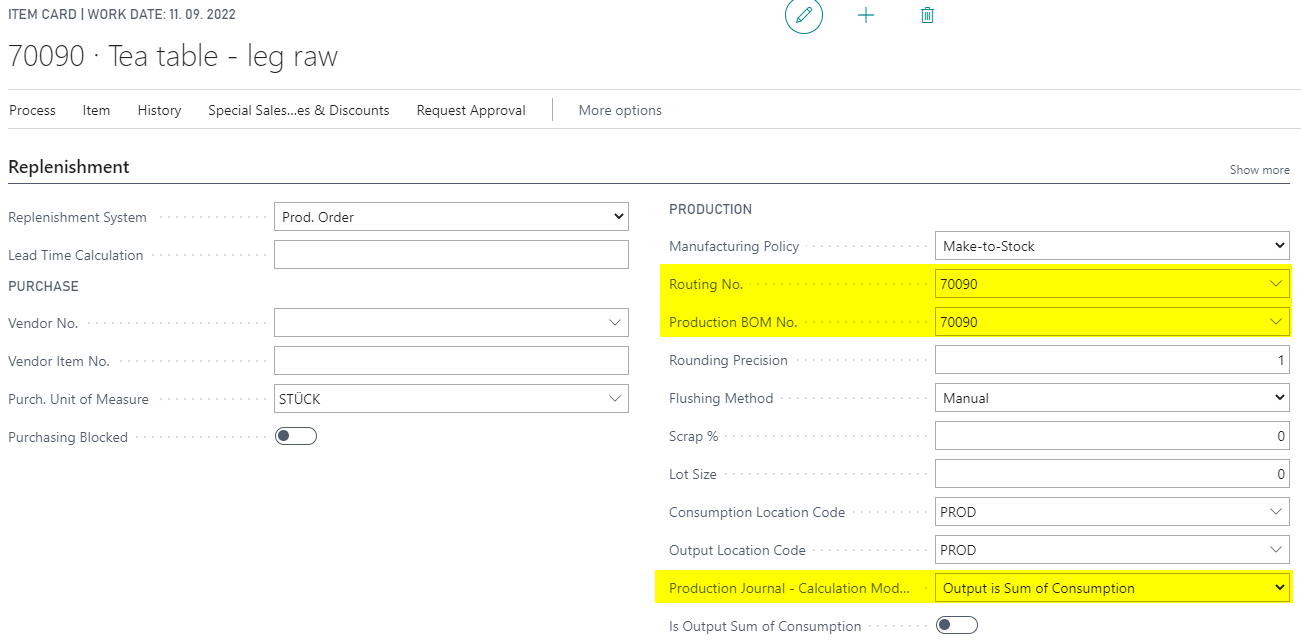

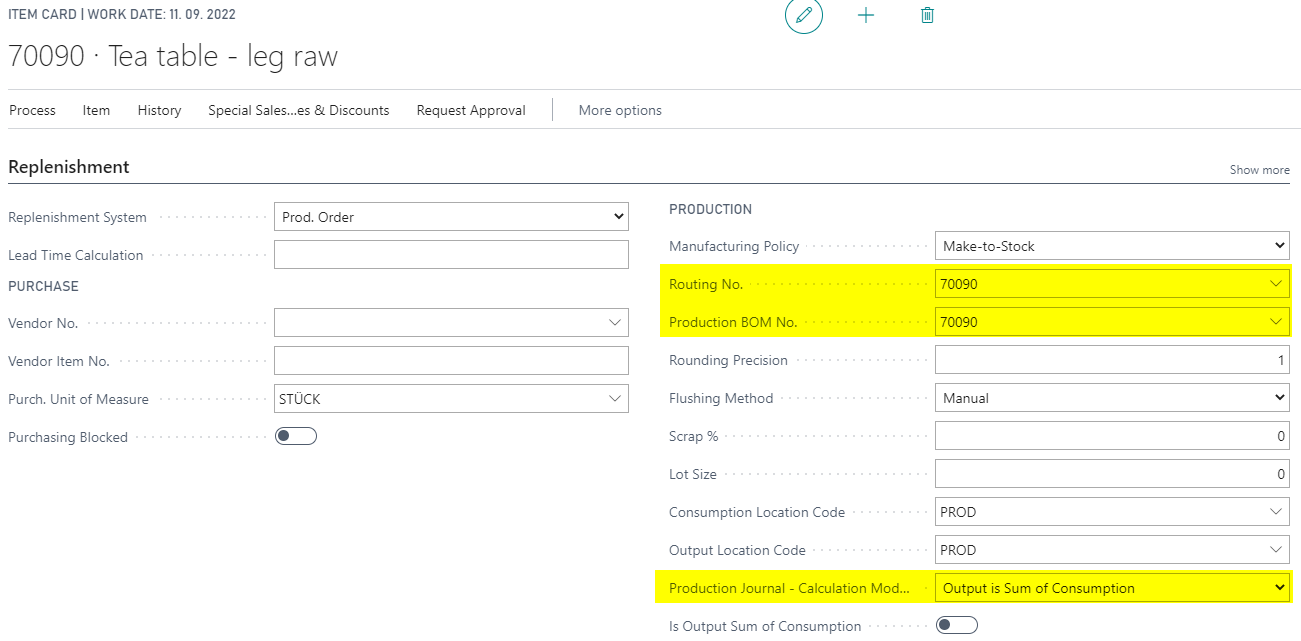

Select an option in field "Production Journal - Calculation Mode for Output and Consumption" on Replenishment tab:

- Standard: Remaining quantity for Output is transferred from the Production Order and the remaining quantity for consumption is transferred from Prod. Order Components Lines.

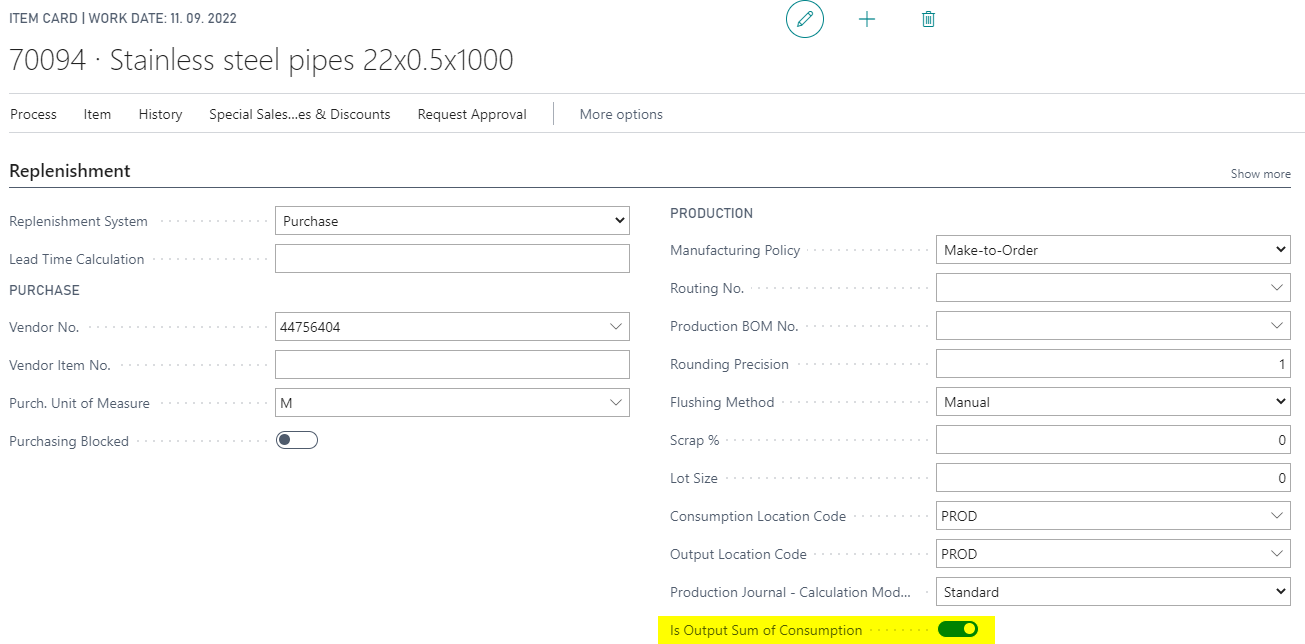

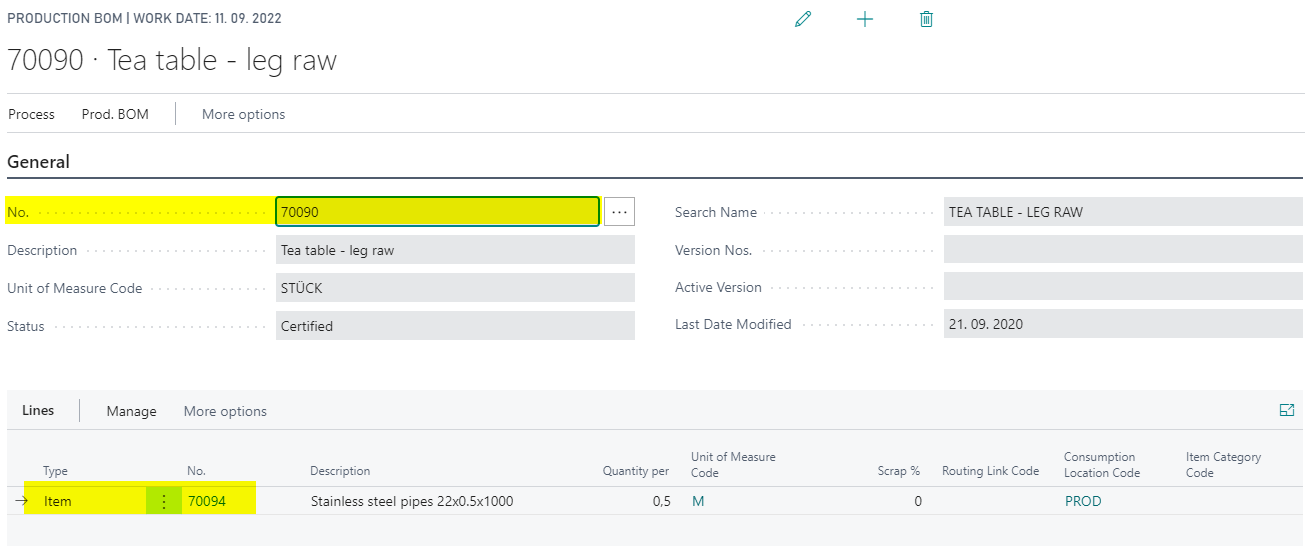

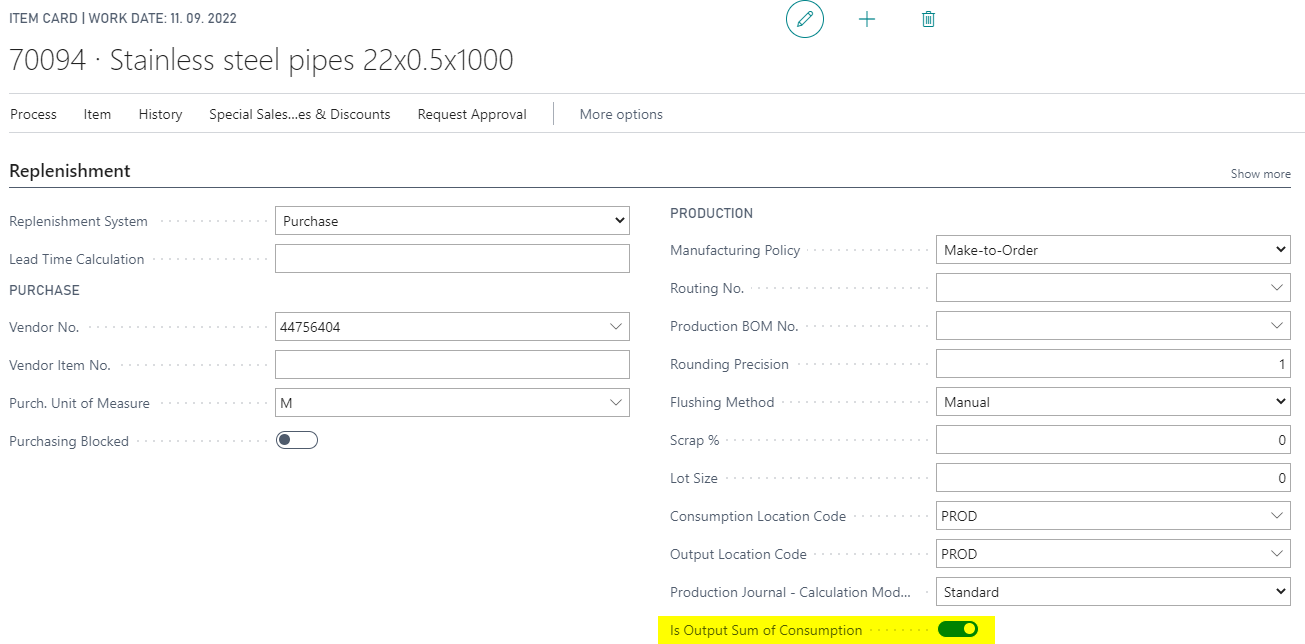

- Output is Sum of Consumption: Output Quantity in Production Journal is calculated based on Consumption Quantities. A user enters consumption in Production Journal. Output quantity is automatically calculated as a sum of Consumption lines with Items that are marked with "Is Output Sum of Consumption" on Item Card. (Output is Sum of Consumption). Selection "Output is Sum of Consumption" is used on a product item, while main ingredient shall be marked with "Is Output Sum of Consumption".

The feature can be used only when you have only one Output Line on Production Journal.

This Calculation Mode is often used in process manufacturing, where Output in direct product of consumed materials (like apple and apple juice).

- Consumption from Output Qty: Consumption in Production Journal is calculated based on Output and Scrap Quantity.

User enters Output quantity and/or Scrap quantity in Production Journal. Consumption is automatically calculated based on entered Output and Scrap Quantity based on the BOM structure. Run time on Output Production Journal Line is updated according to Output and Scrap Quantity.

-

Choose Routing No. with some lines for Work Center and other information.

-

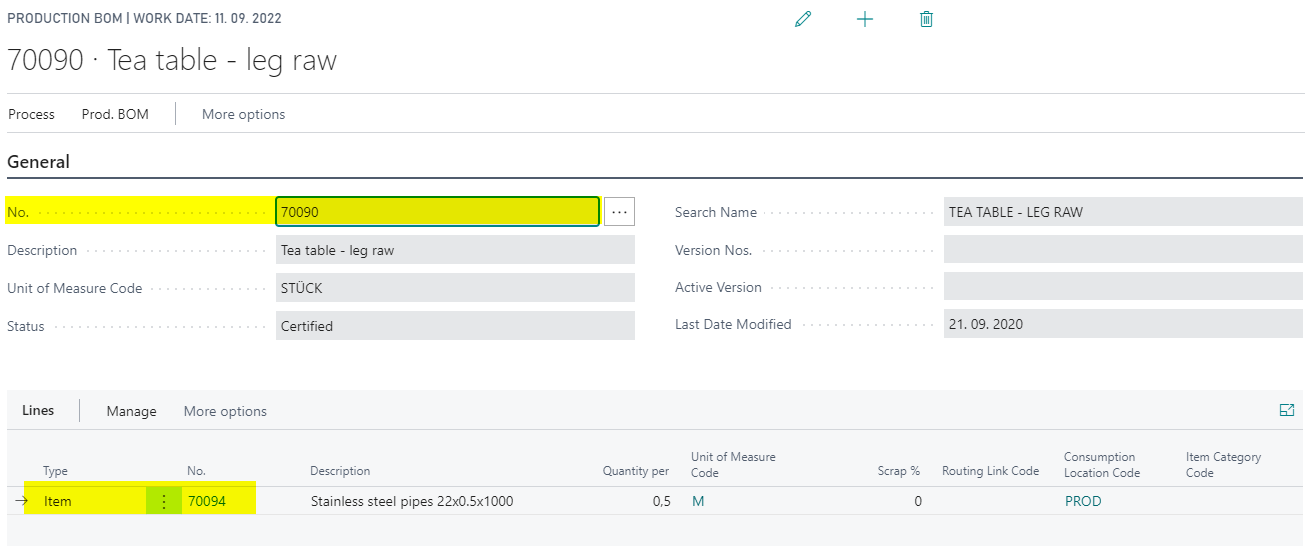

Choose Production BOM No. with some Items that are included in the produced items.

- Define Item from BOM as main ingredient.

Production Order with Standard option on Item Card

Use Item / Product with following parameters.

- Open Released Production Order:

- Select created Item in Source No. and enter Quantity.

- Select Item in Production Order Line.

- Push button Refresh Production Order in Process ribbon.

- Open Production Journal by choosing button Production Journal on Lines/Line Tab.

- Enter Consumption Quantity:

- Field Output Quantity on Production Journal will not change.

- Field Run Time on Output Production Journal Line will not change.

- Enter Output Quantity:

- Field Consumption quantity on Production Journal will not change.

- Field Run Time on Output Production Journal Line will be recalculated according to Routing Line.

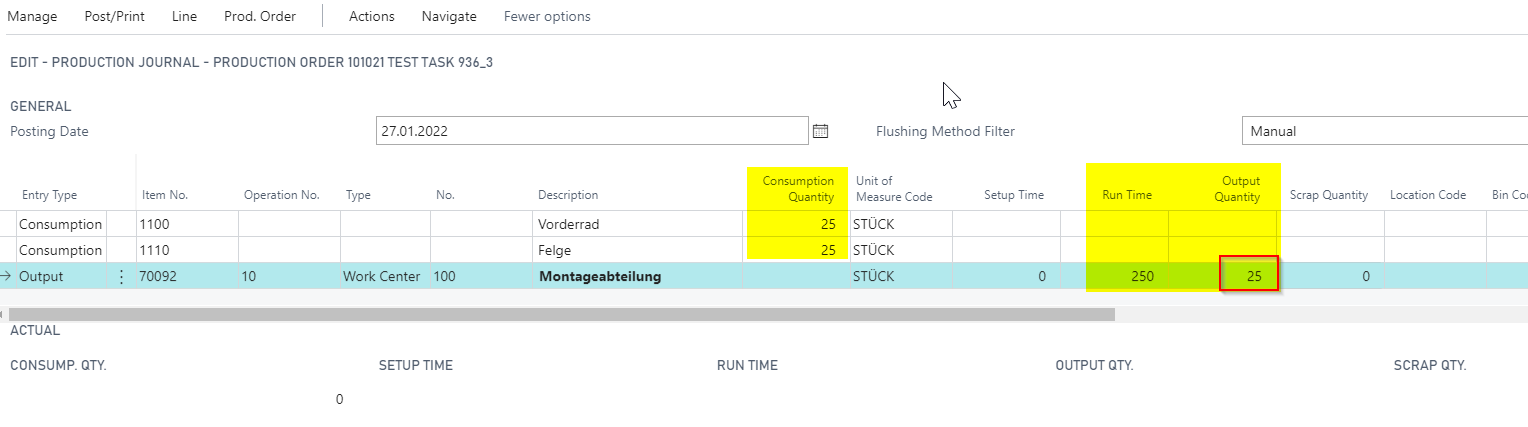

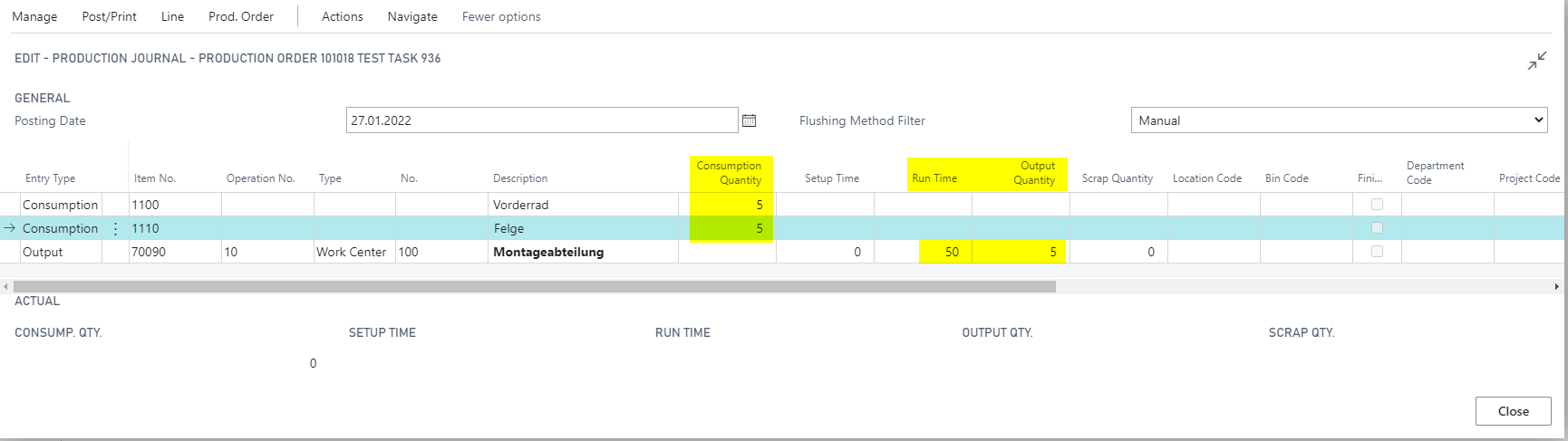

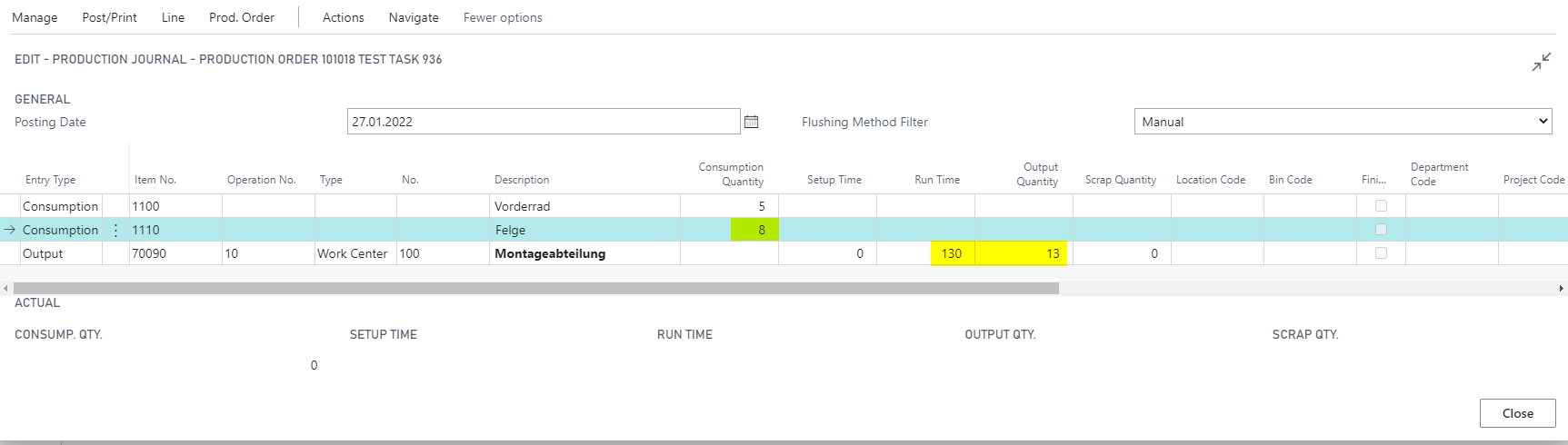

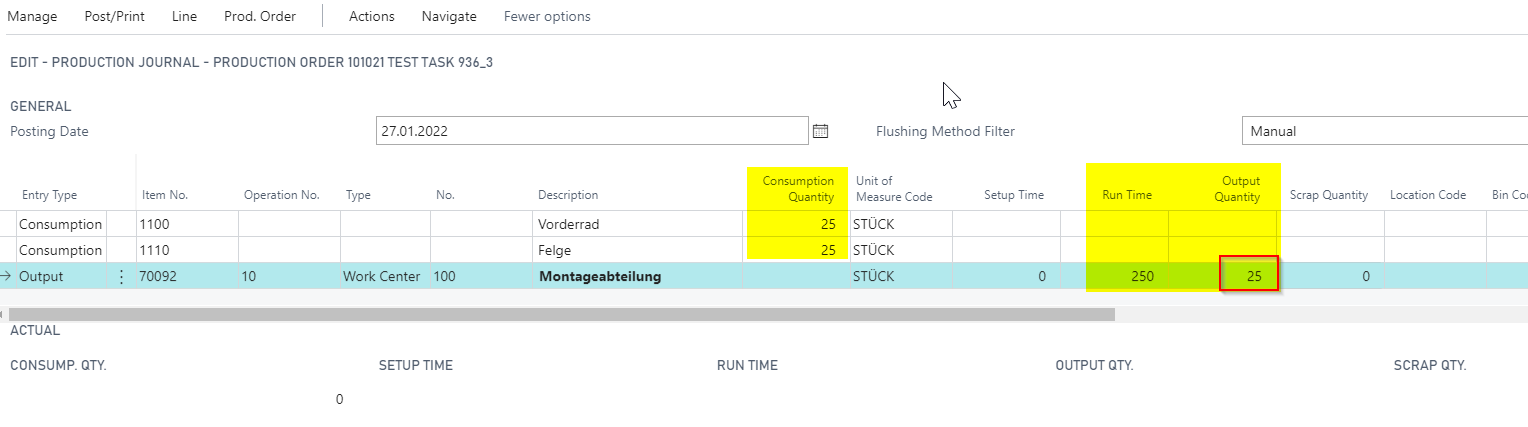

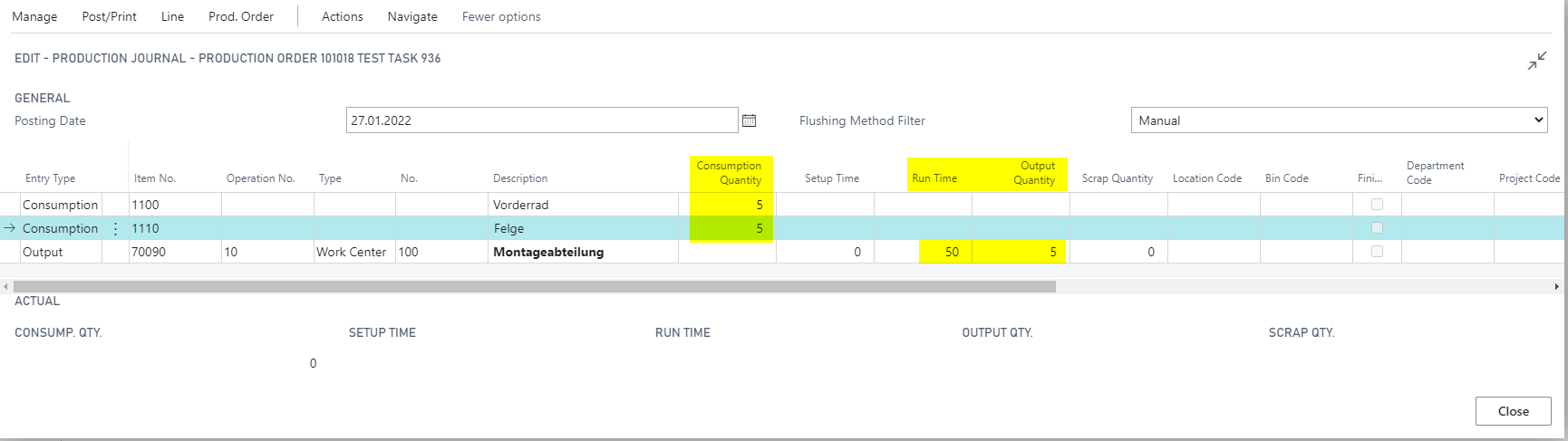

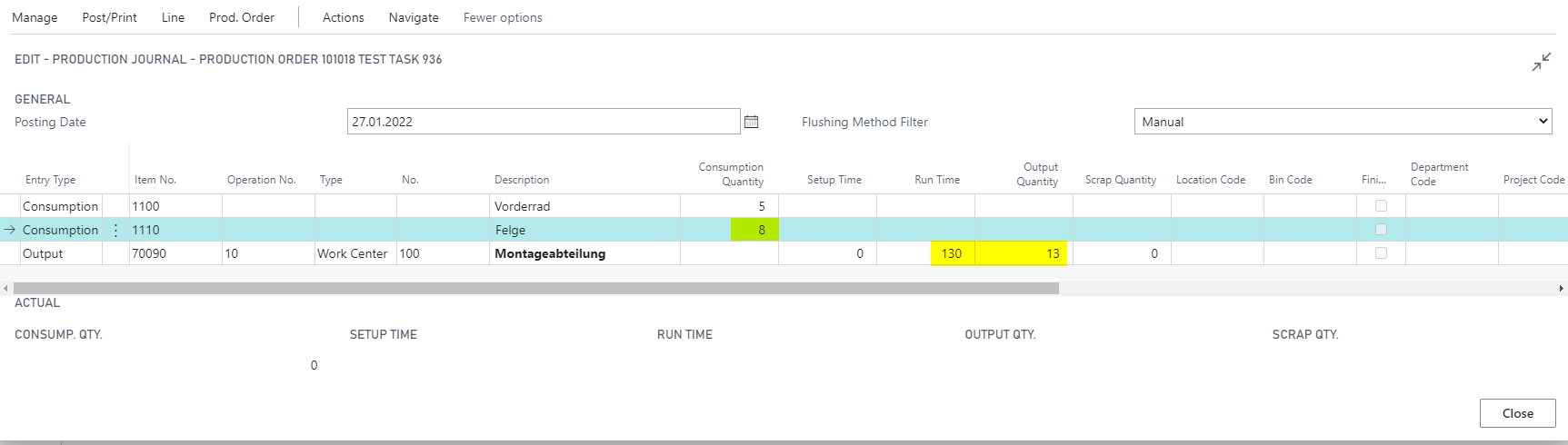

Production Order with Output is Sum of Consumption option on Item Card

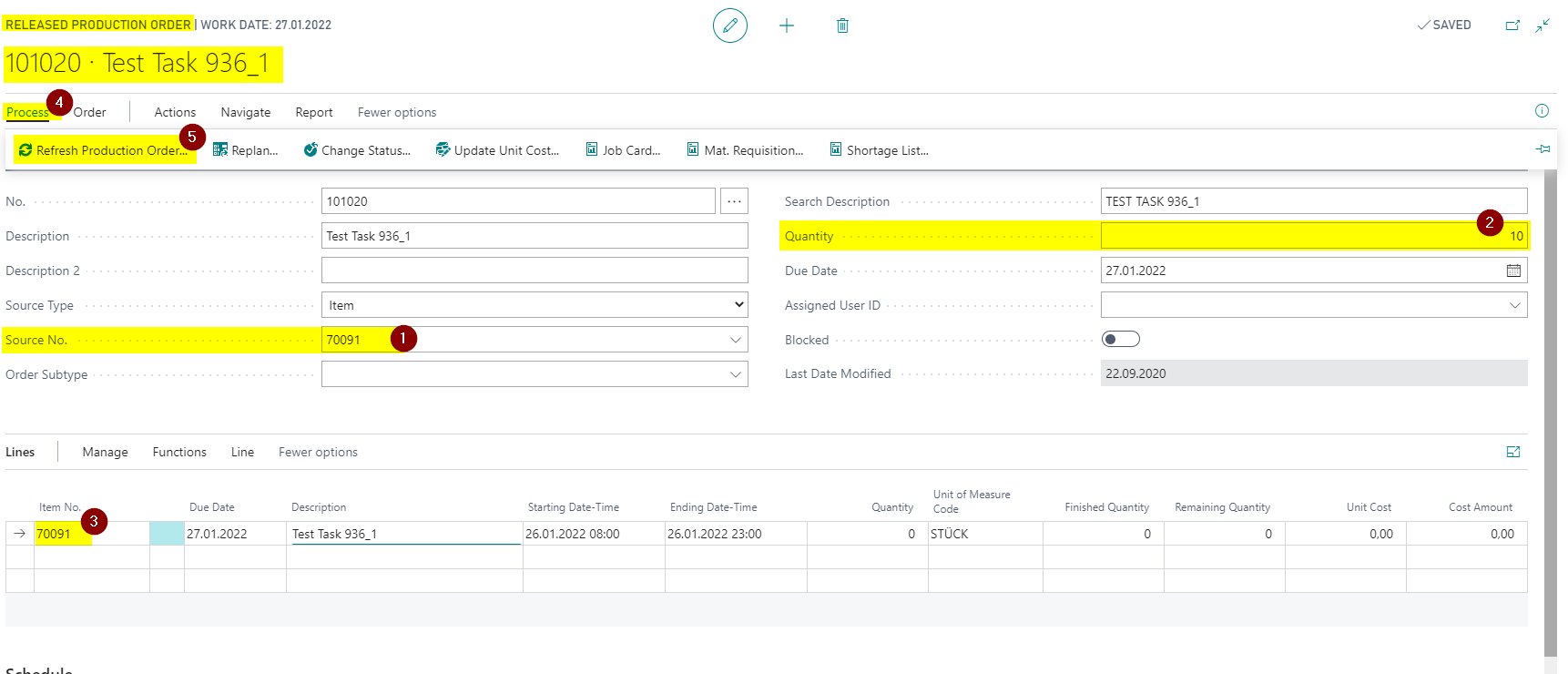

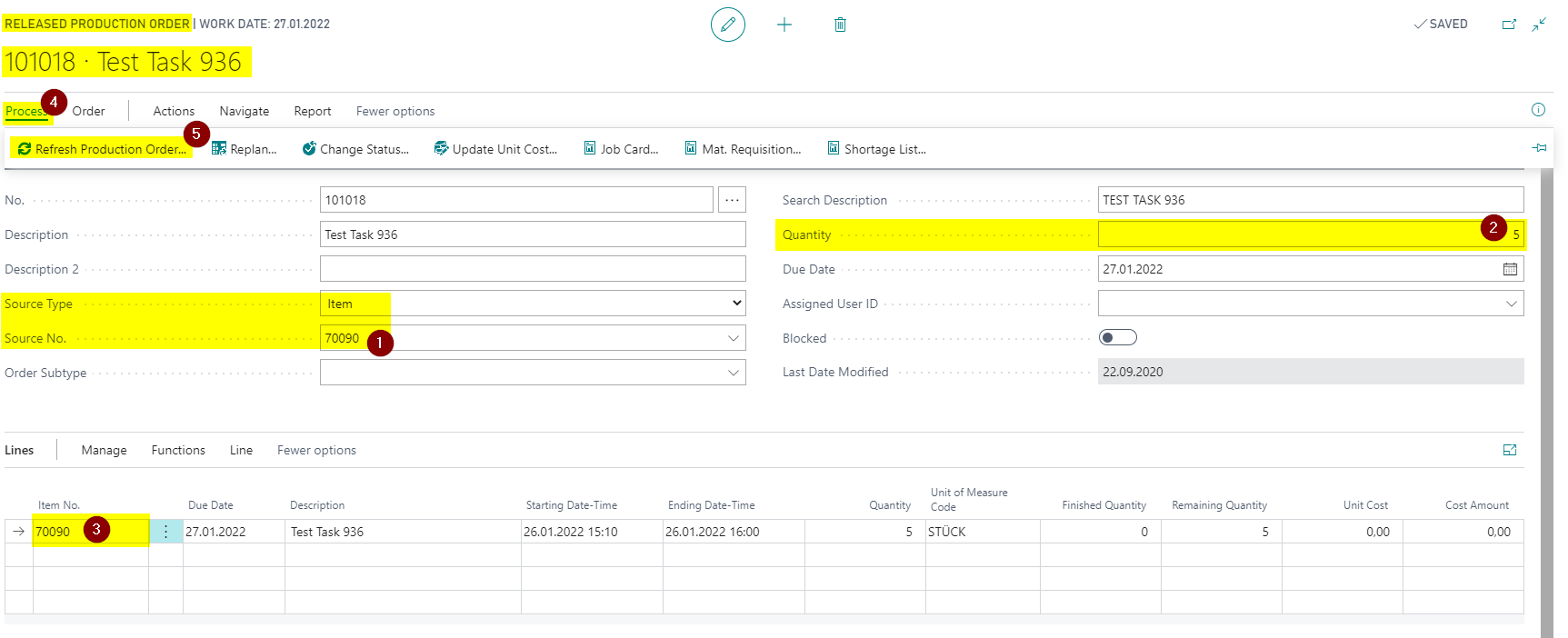

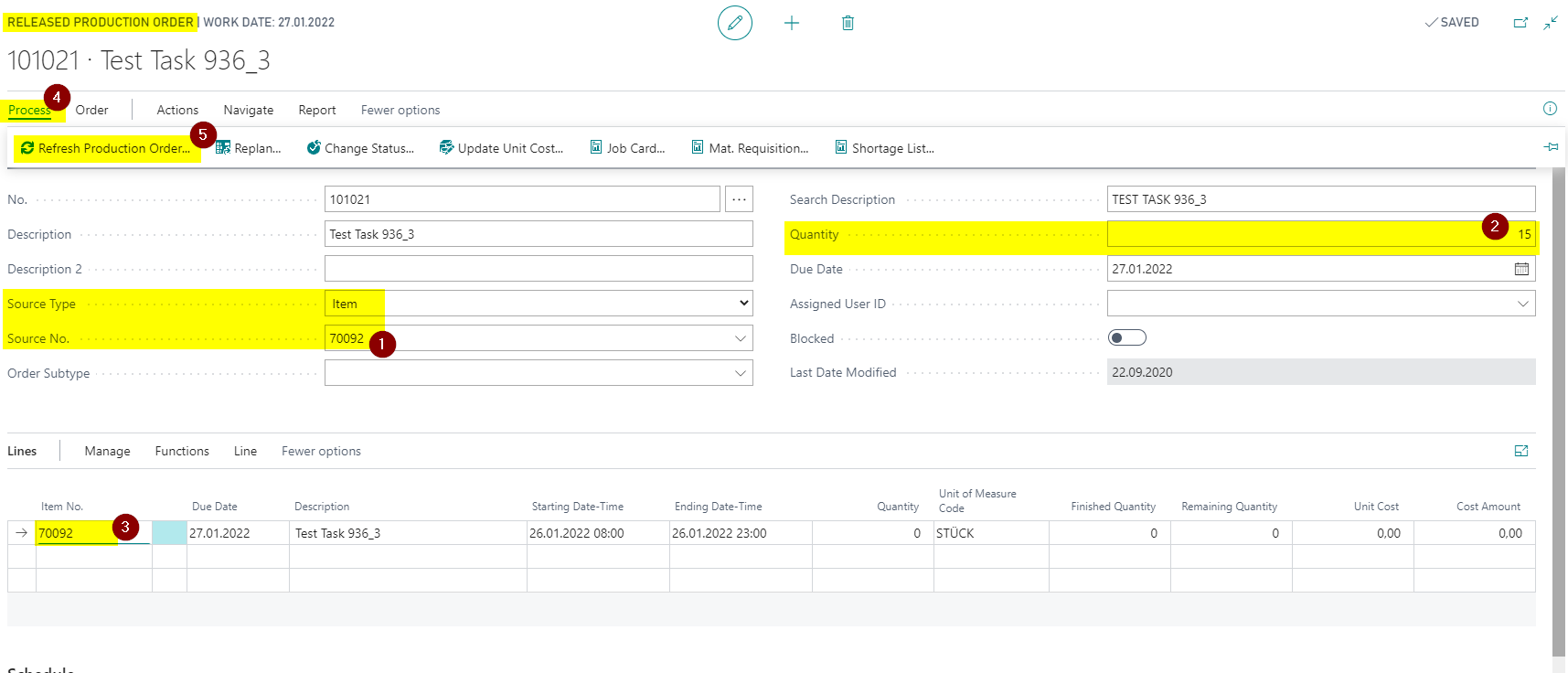

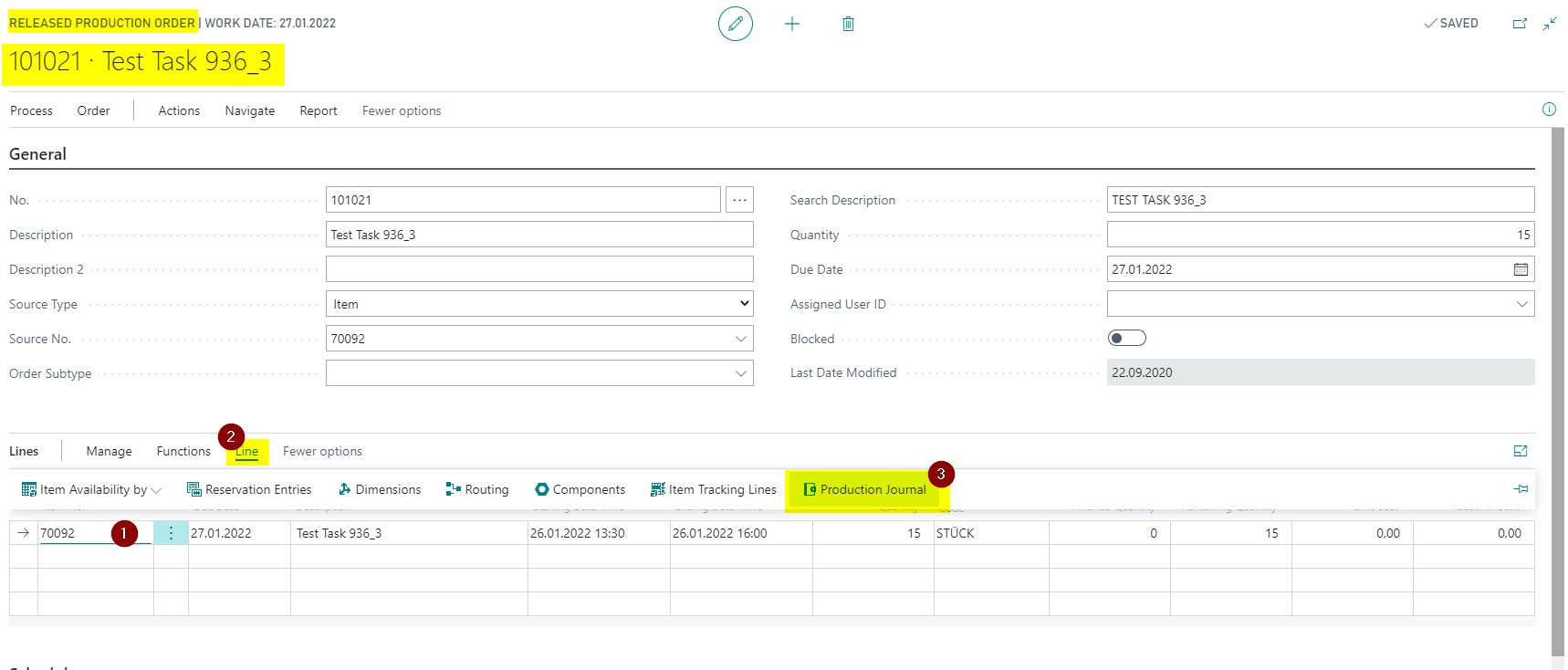

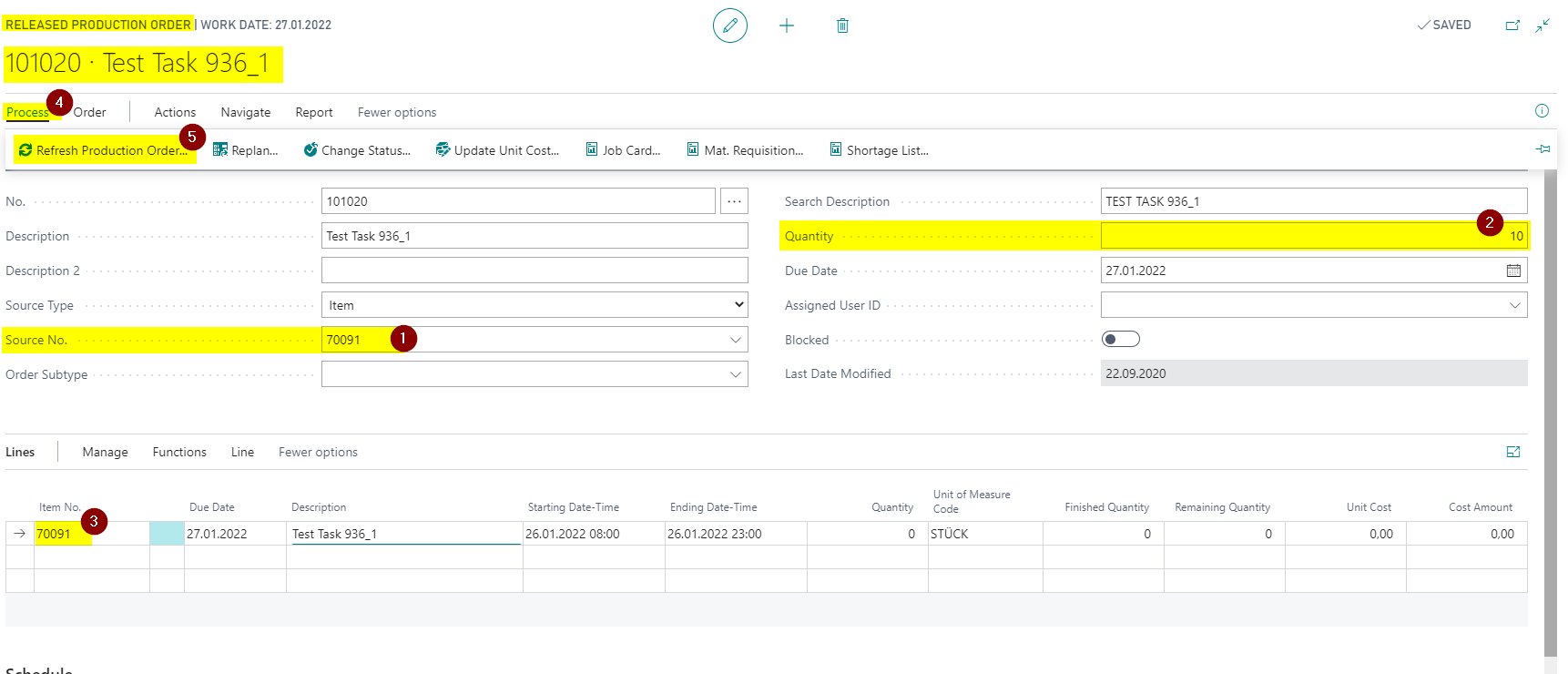

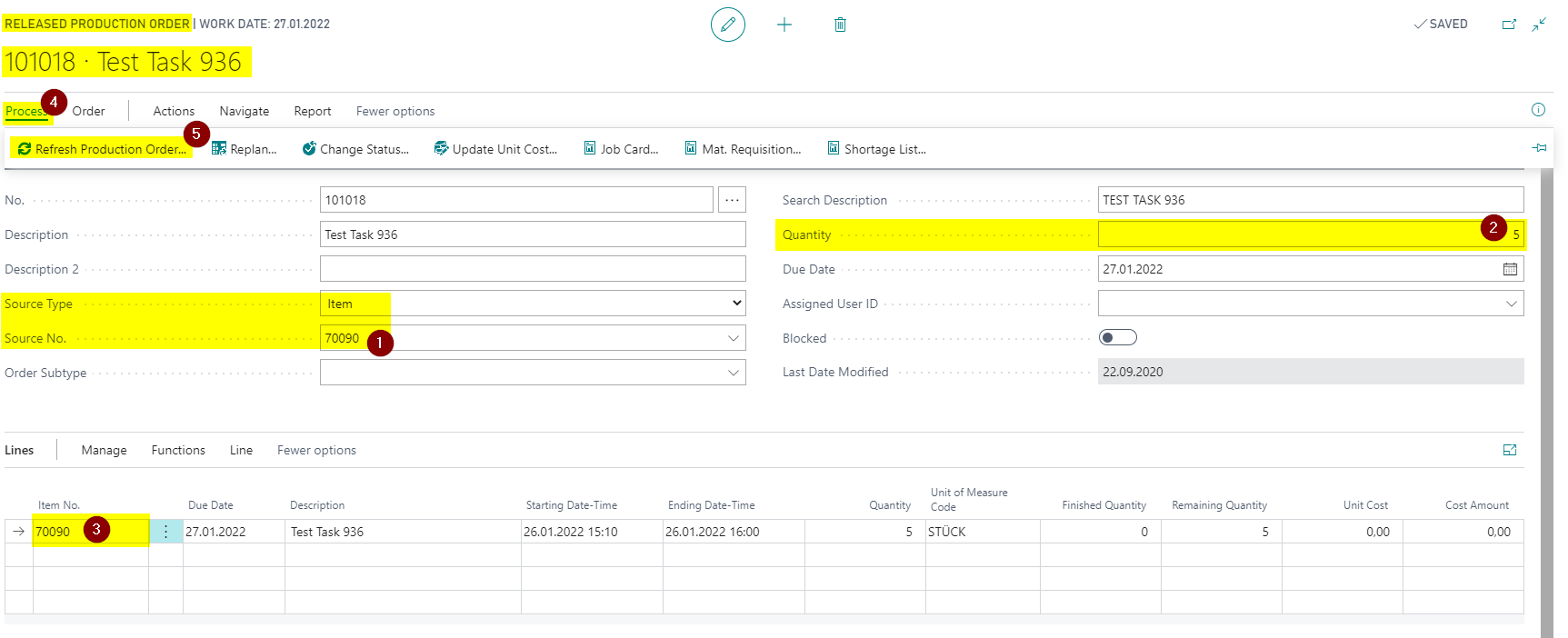

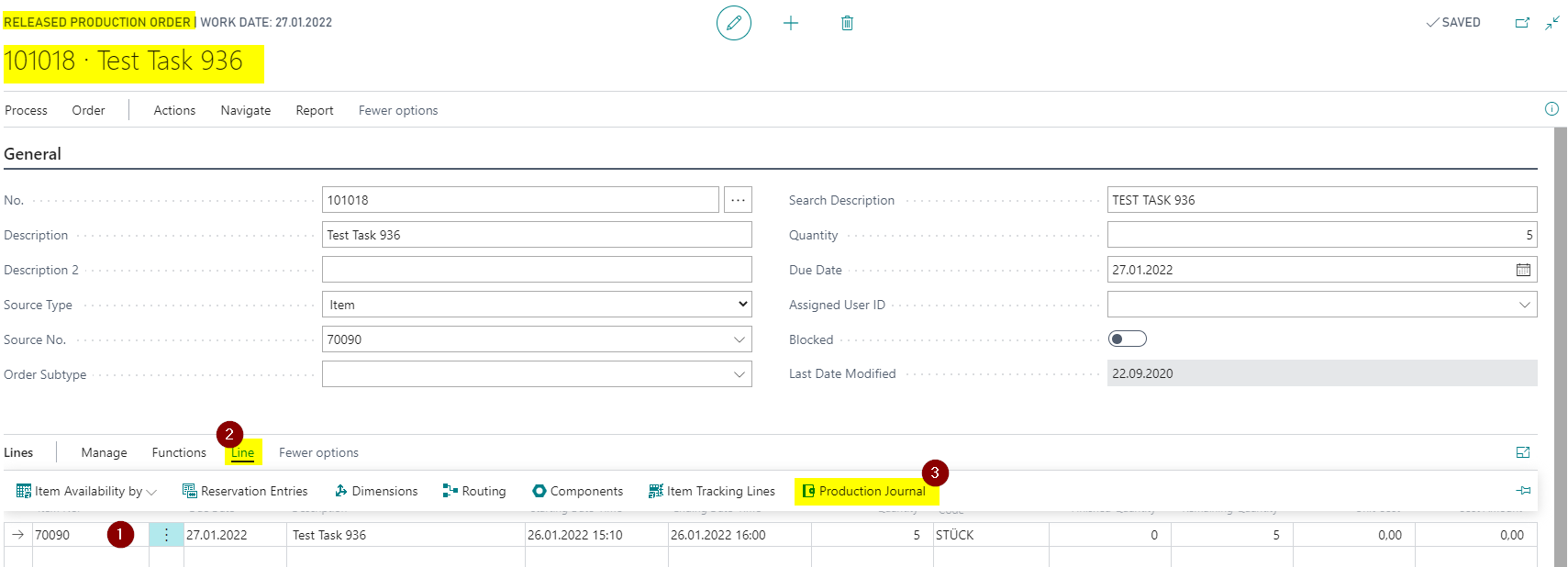

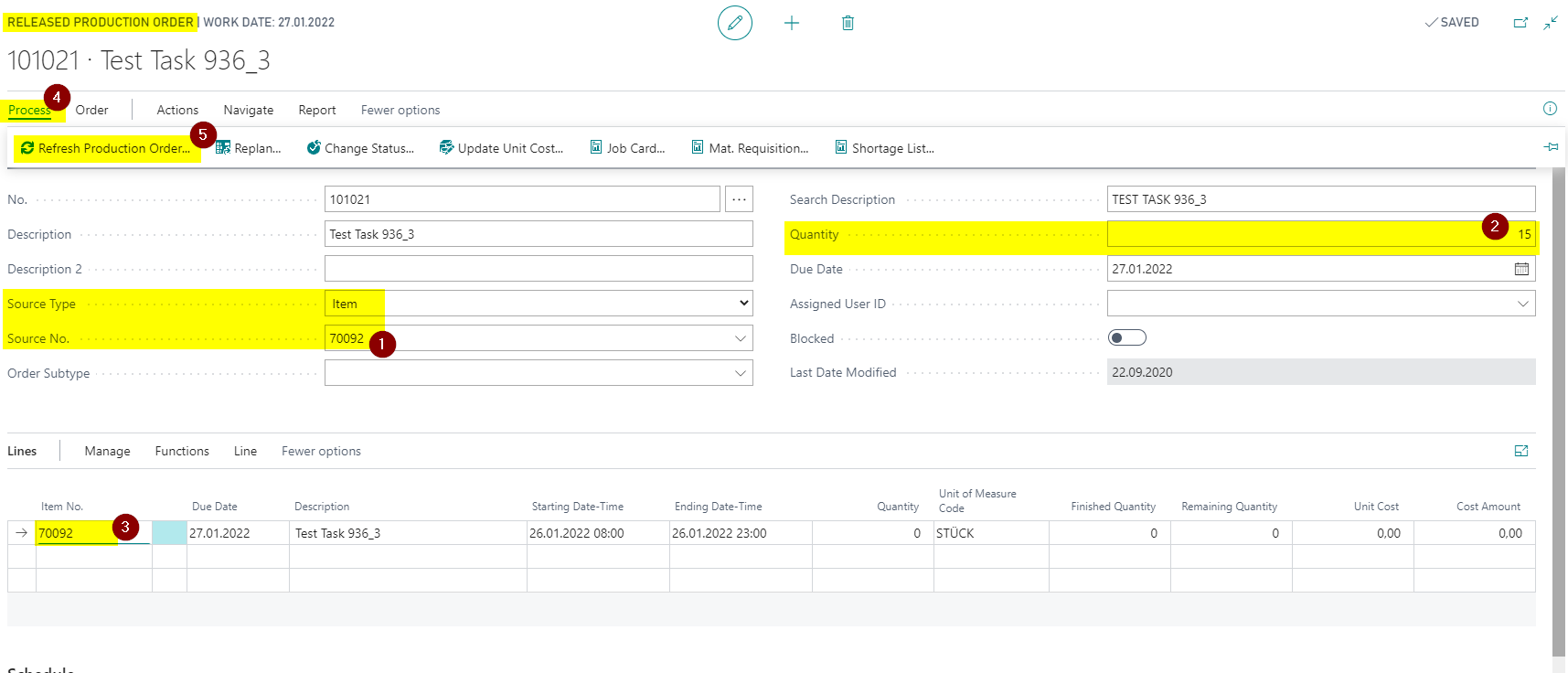

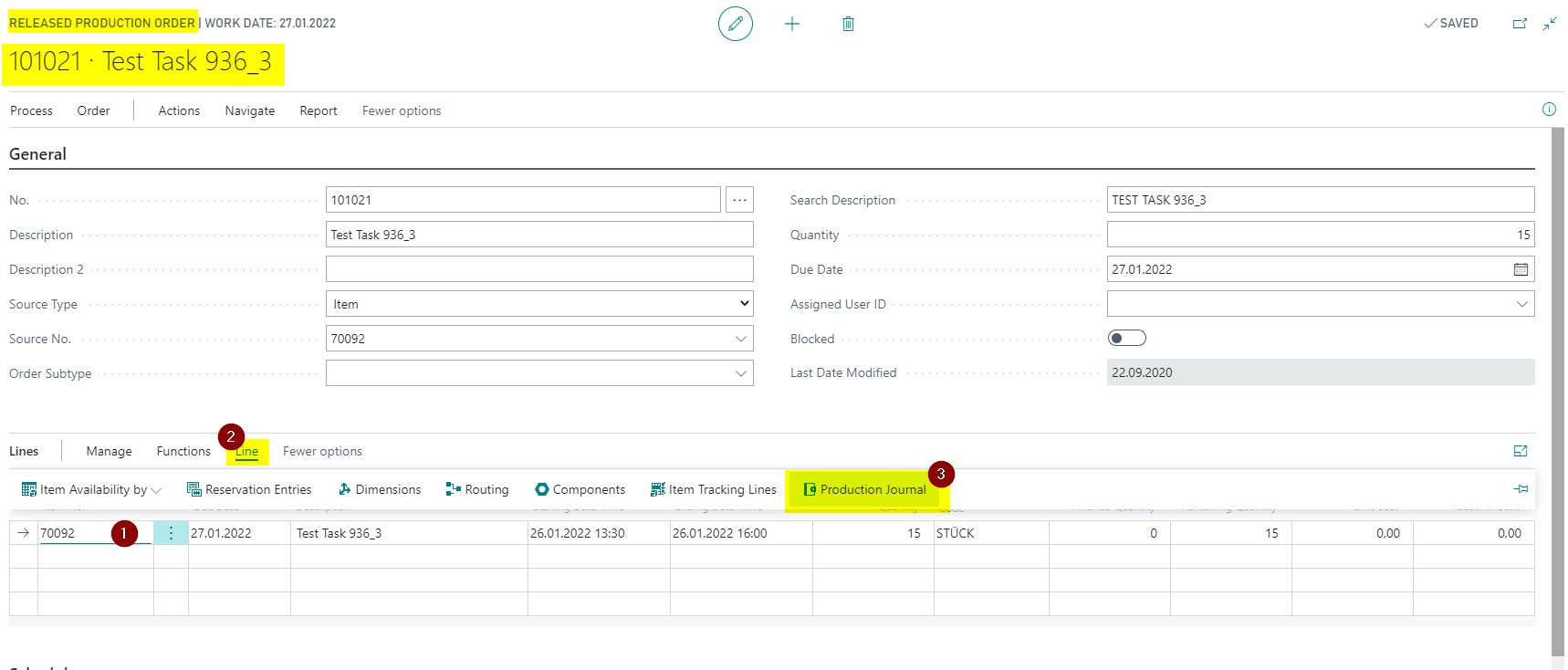

- Open Released Production Order:

- Select created Item in Source No. and enter Quantity.

- Select Item in Production Order Line.

- Push button Refresh Production Order in Process ribbon.

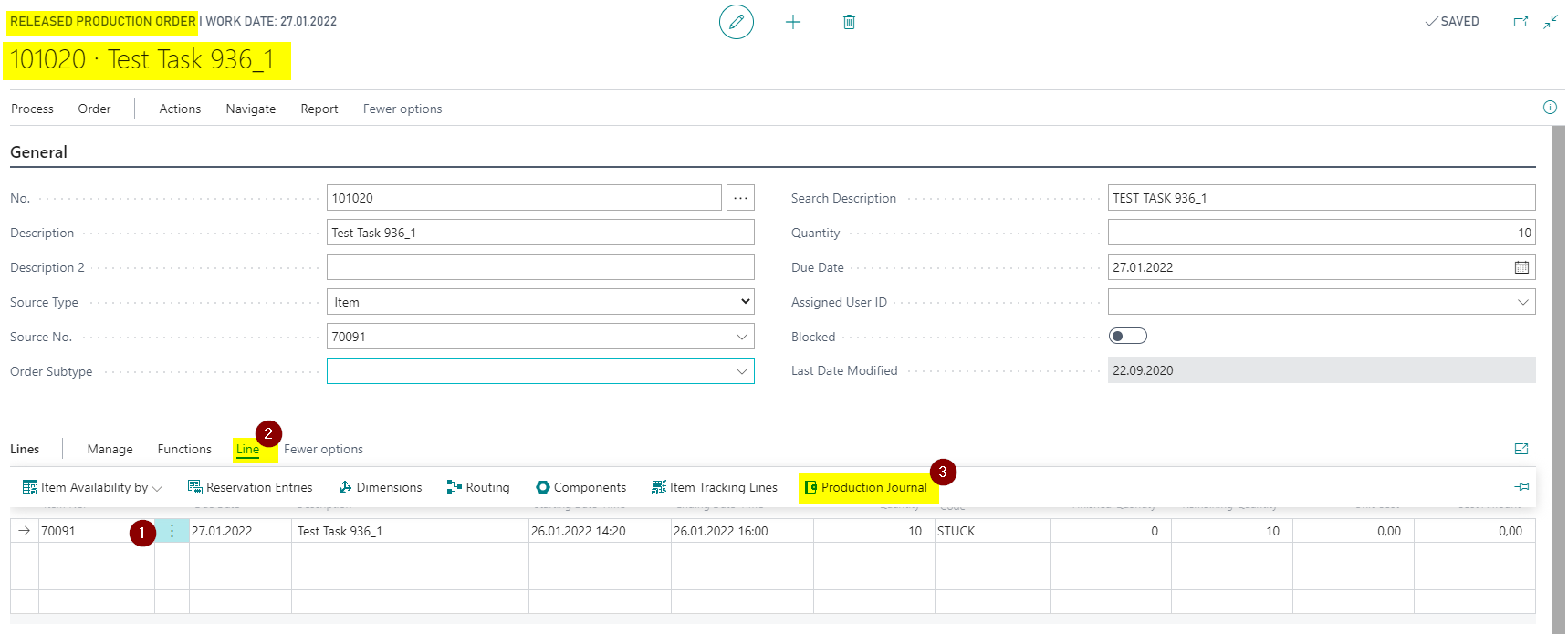

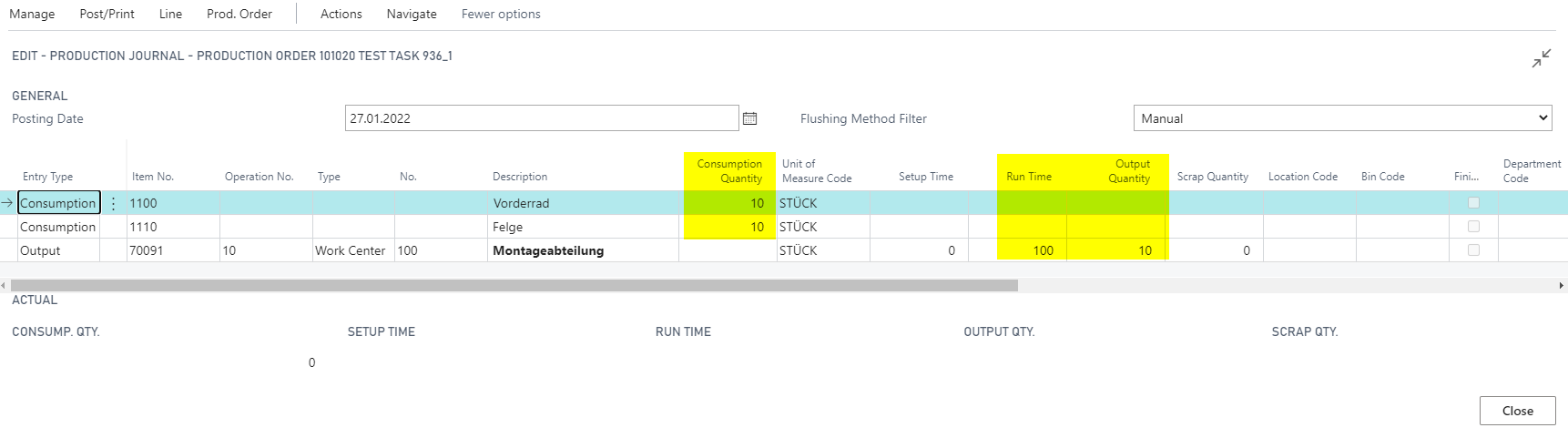

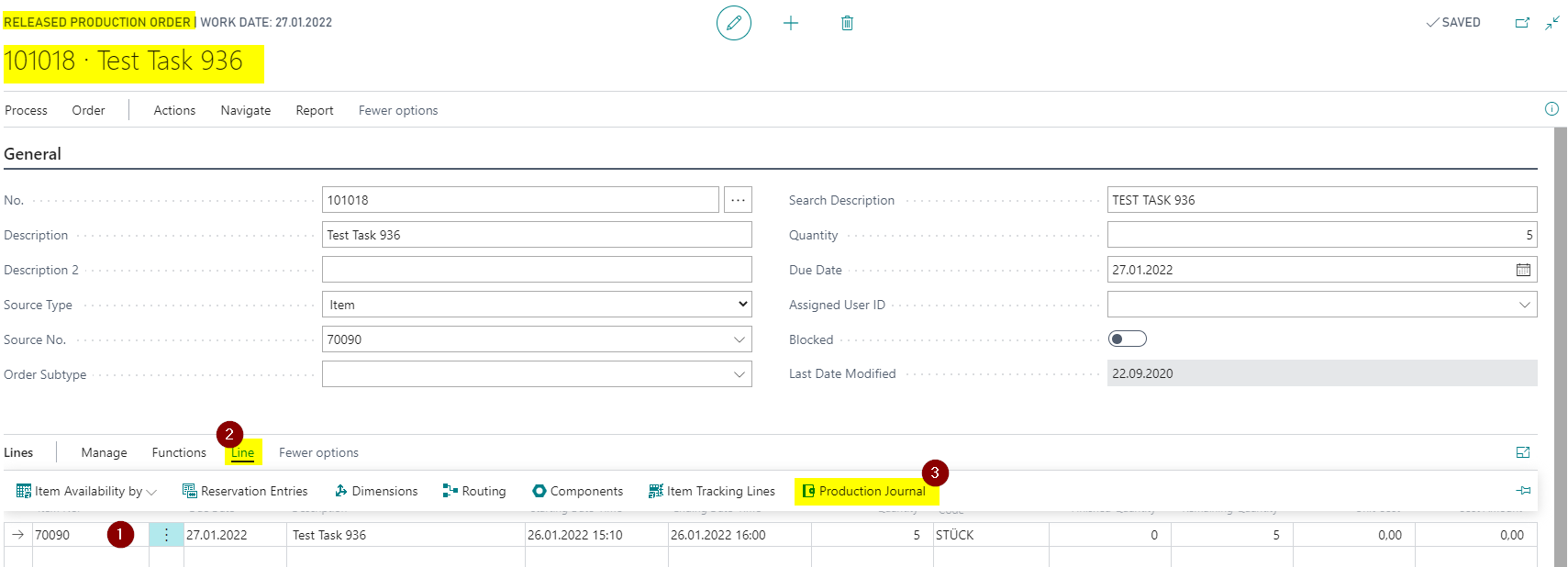

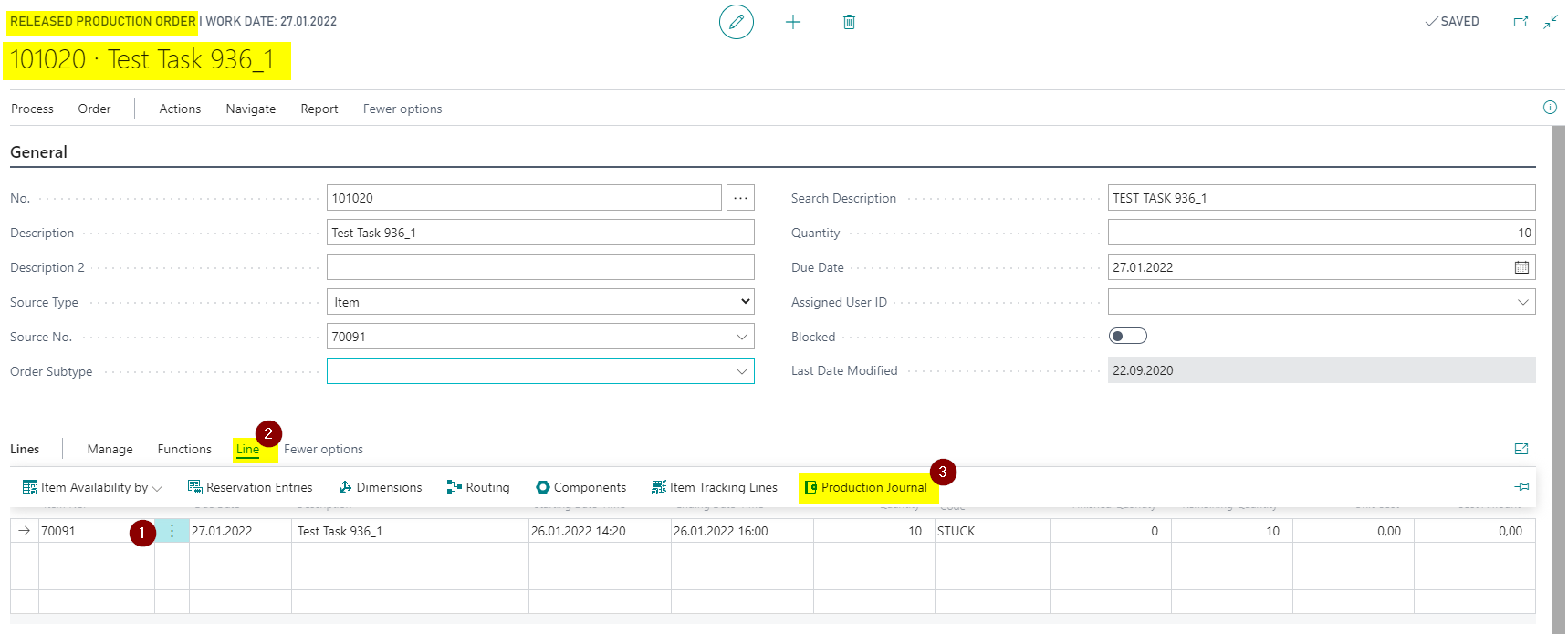

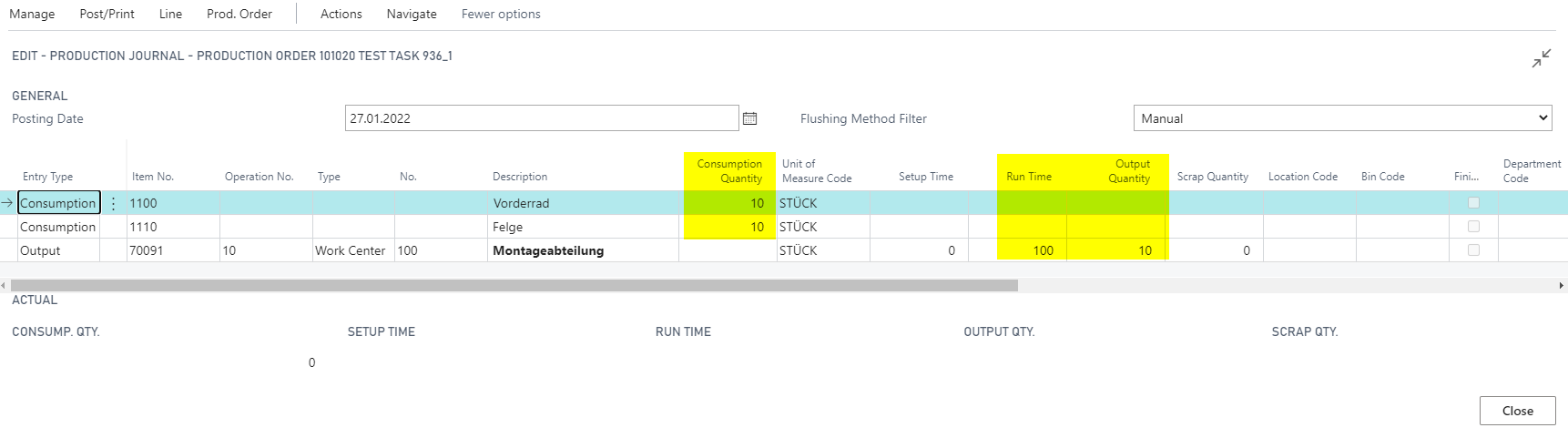

- Open Production Journal by choosing button Production Journal on Lines/Line Tab.

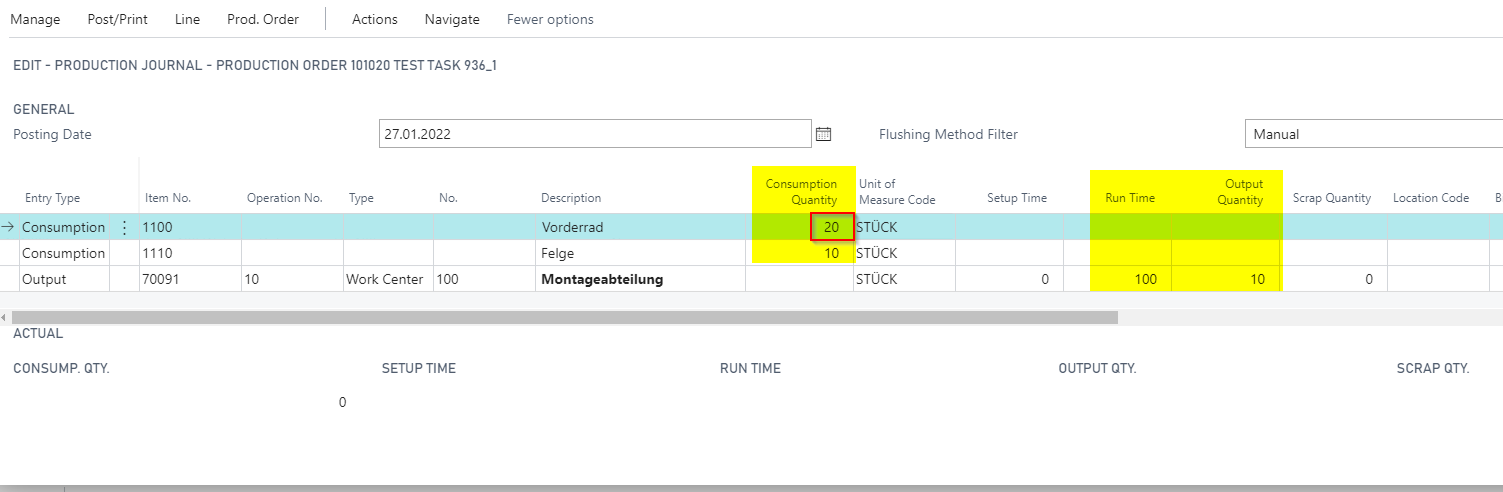

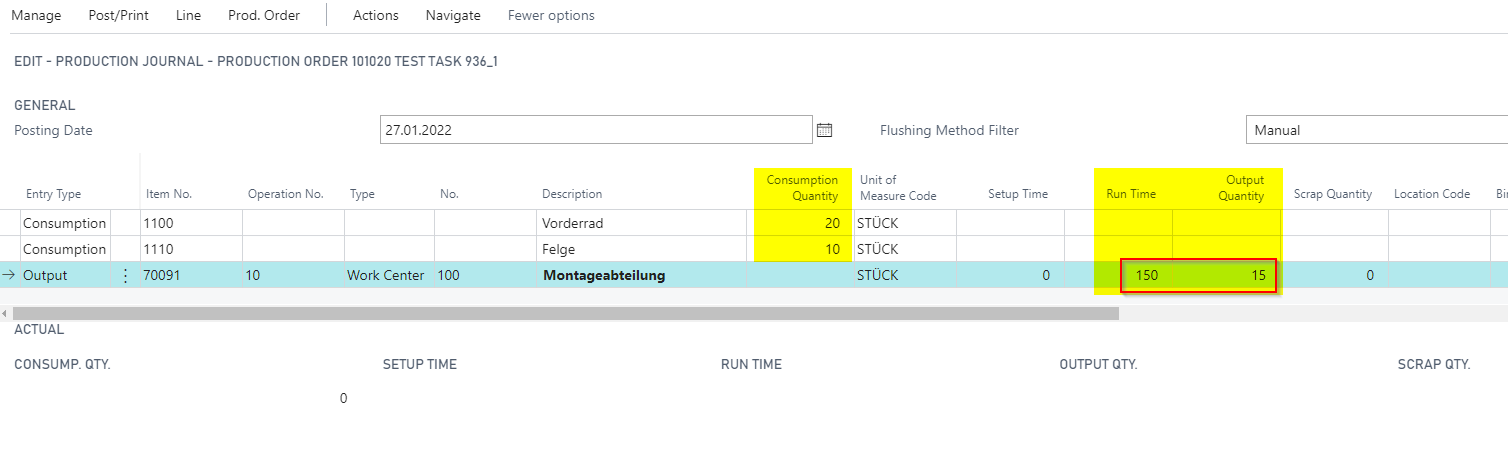

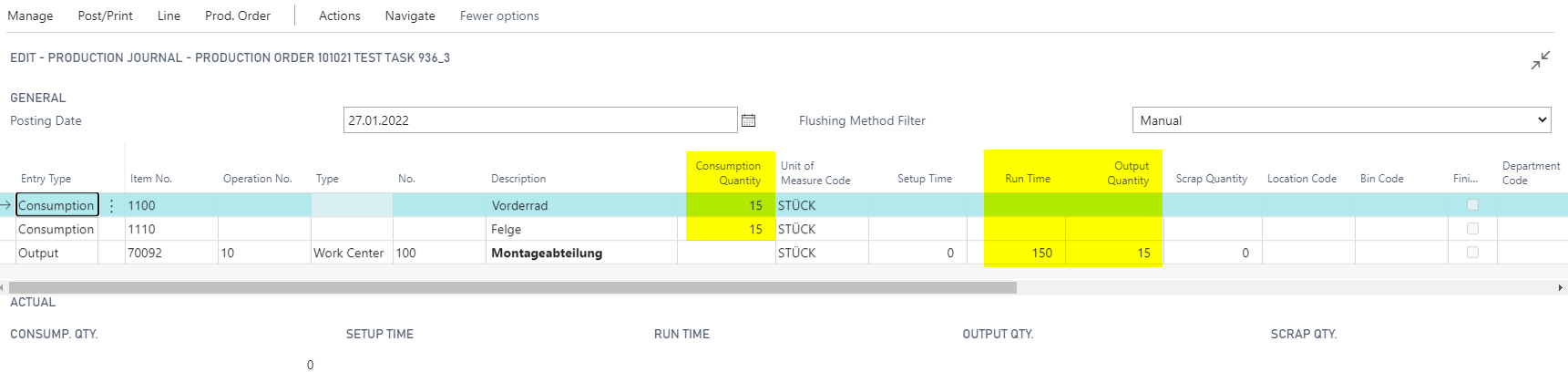

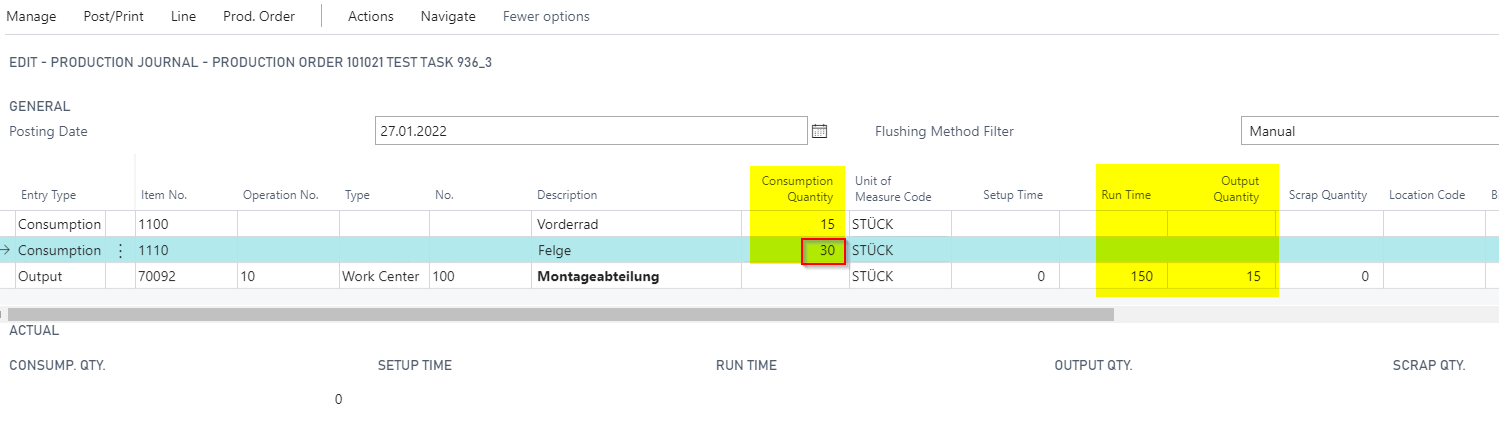

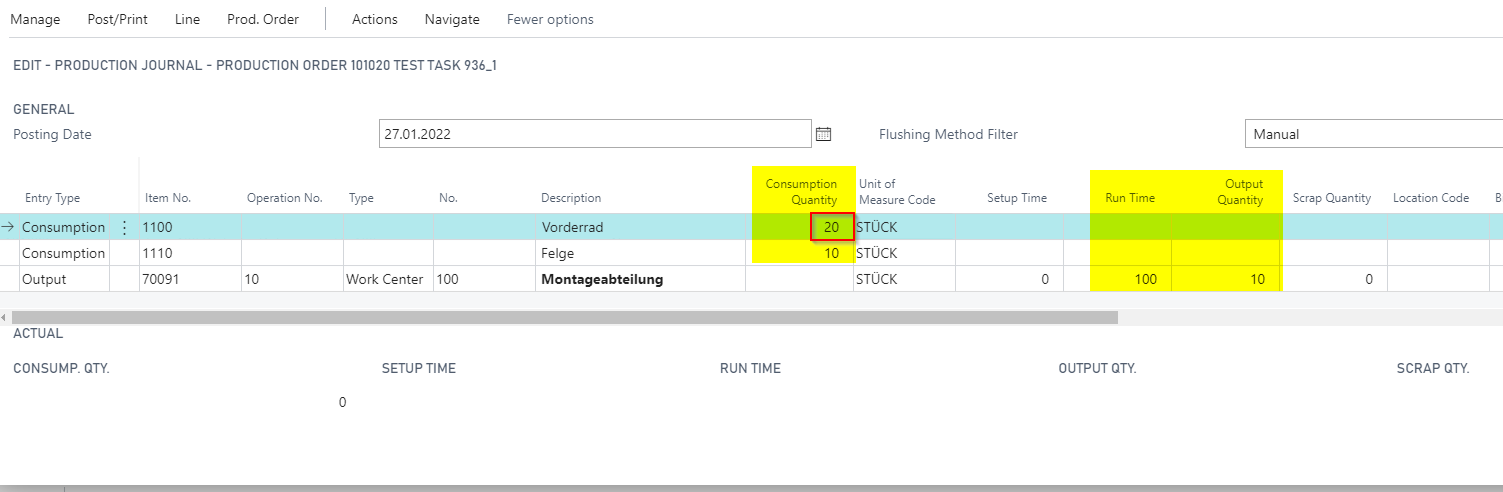

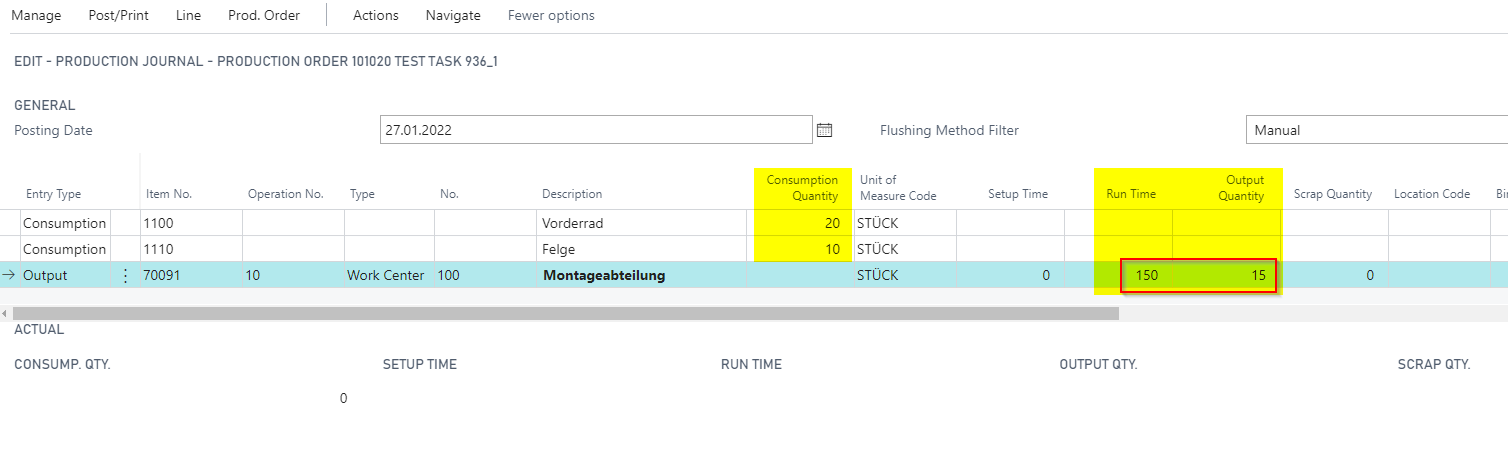

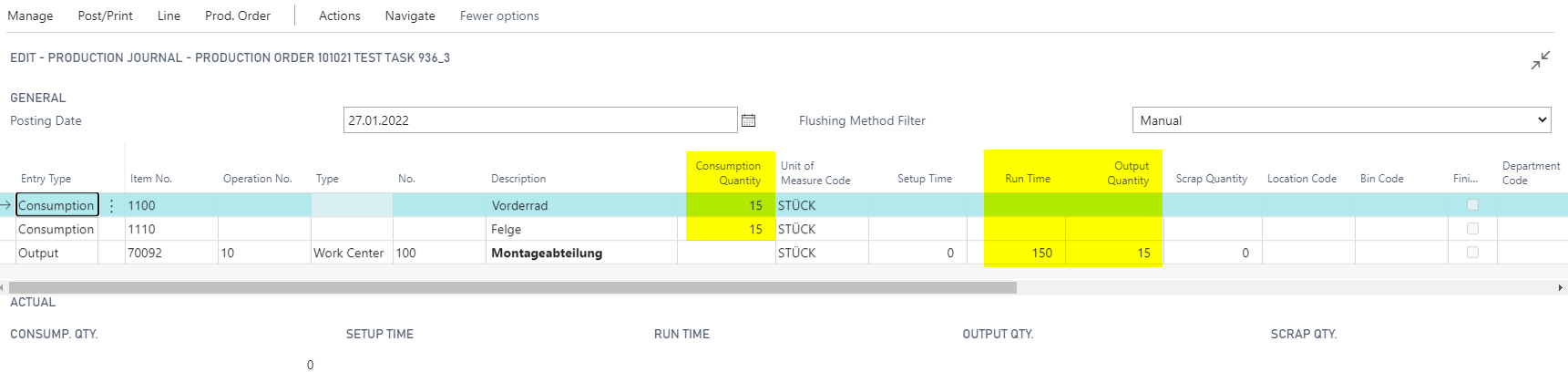

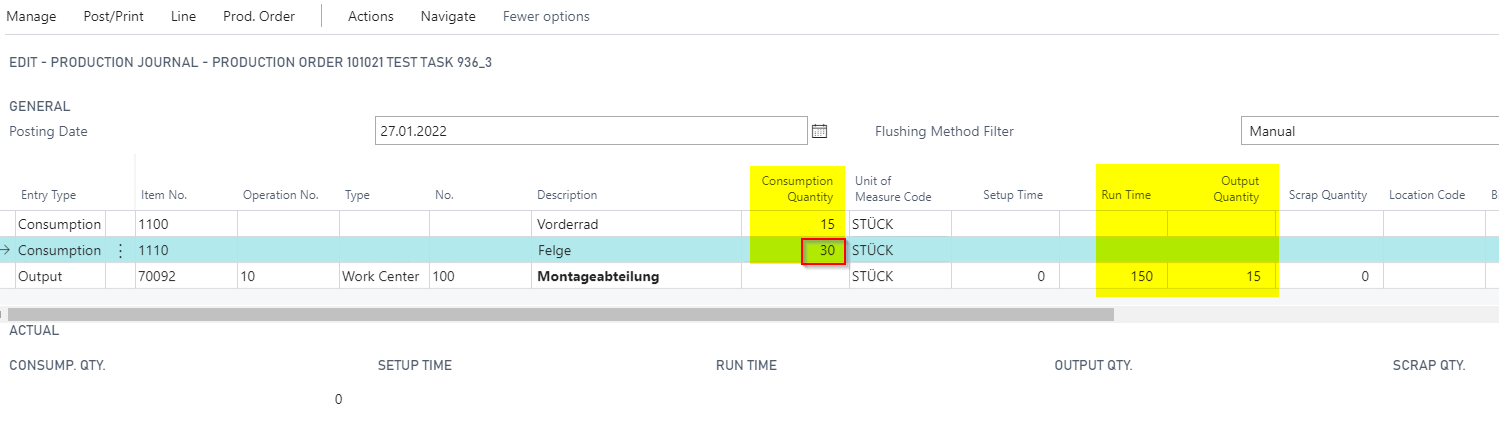

- Enter Consumption quantity:

- Field Output quantity on Production Journal will be recalculated as SUM of Consumption lines with Items that are marked as Is Output Sum of Consumption on Item Card.

- Field Run Time on Output Production Journal Line will be recalculated according to Routing Line.

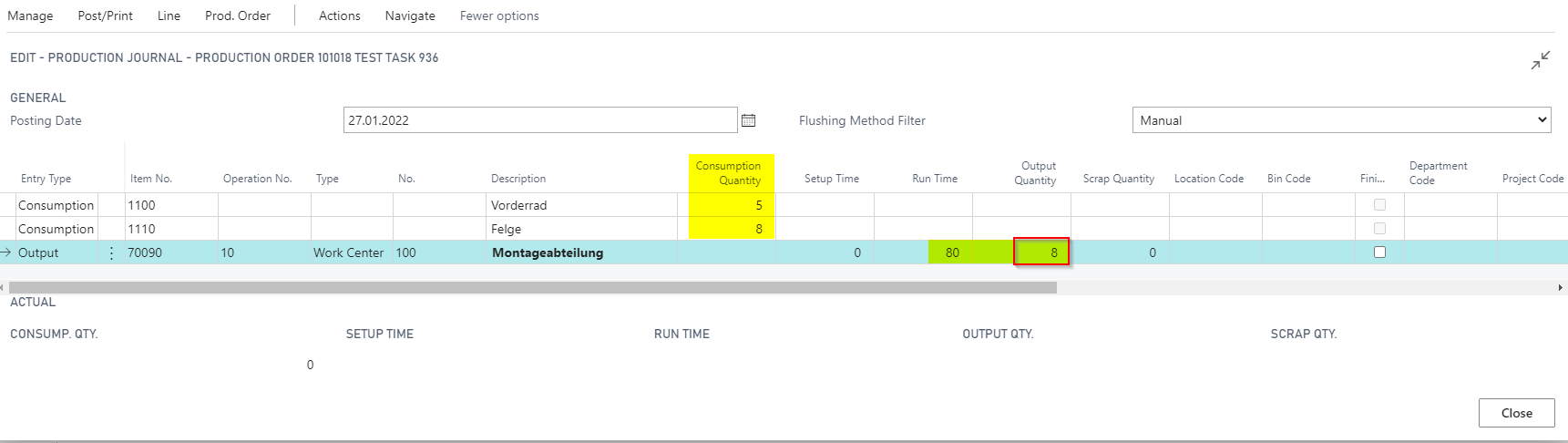

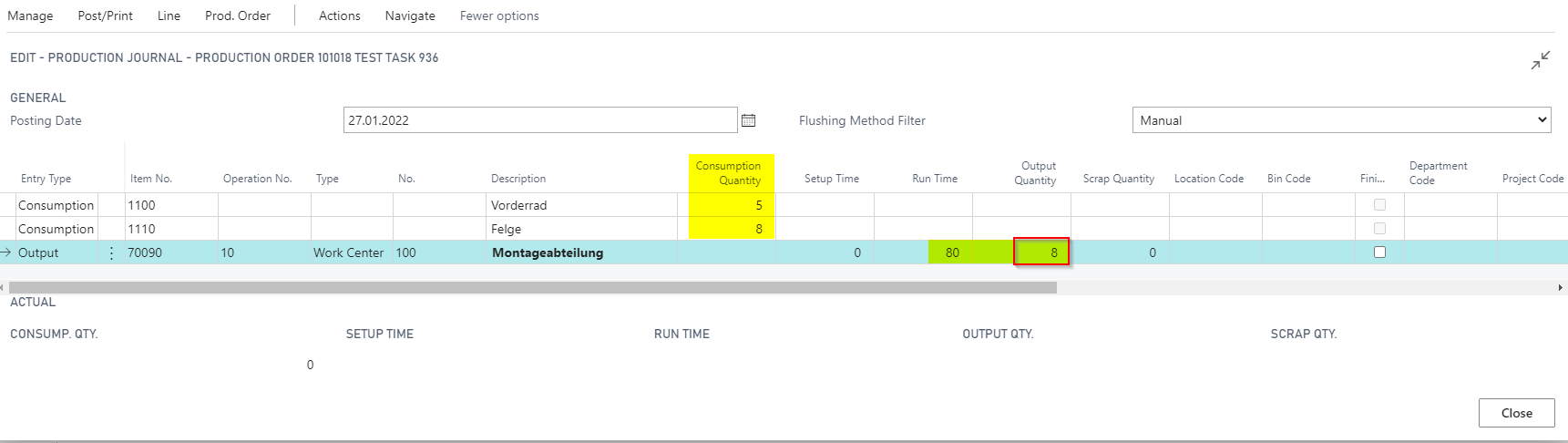

- Enter Output quantity:

- Field Consumption quantity on Production Journal will not change.

- Field Run Time on Output Production Journal Line will be recalculated according to Routing Line.

Production Order with Consumption from Output Qty option on Item Card

- Open Released Production Order:

- Select created Item in Source No. and enter Quantity.

- Select Item in Production Order Line.

- Push button Refresh Production Order in Process ribbon.

- Open Production Journal by choosing button Production Journal on Lines/Line Tab.

- Enter Consumption Quantity:

- Field Output Quantity on Production Journal will not change.

- Field Run Time on Output Production Journal Line will not change.

- Enter Output Quantity:

- Field Consumption Quantity on Production Journal will be recalculated according to the Prod. Order Components.

- Field Run Time on Output Production Journal Line will be recalculated according to Routing Line.