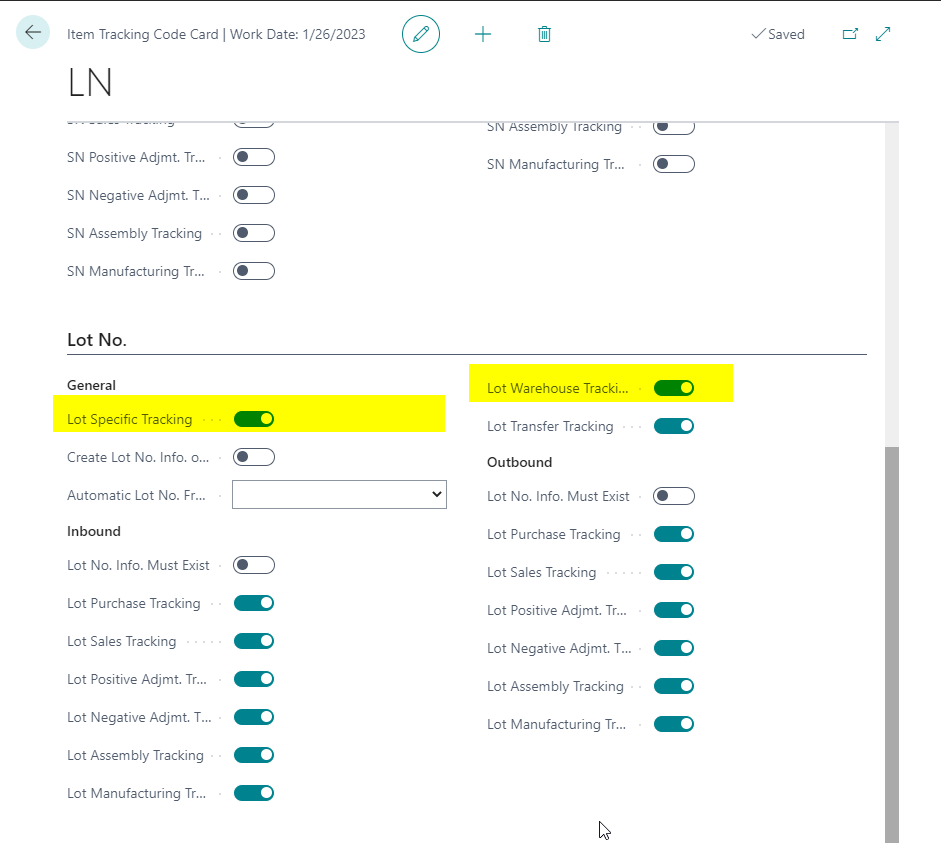

In some companies it is required to have a very specific tracking of the component Lot No. that you use to produce a product that also must be tracked with a Lot No.

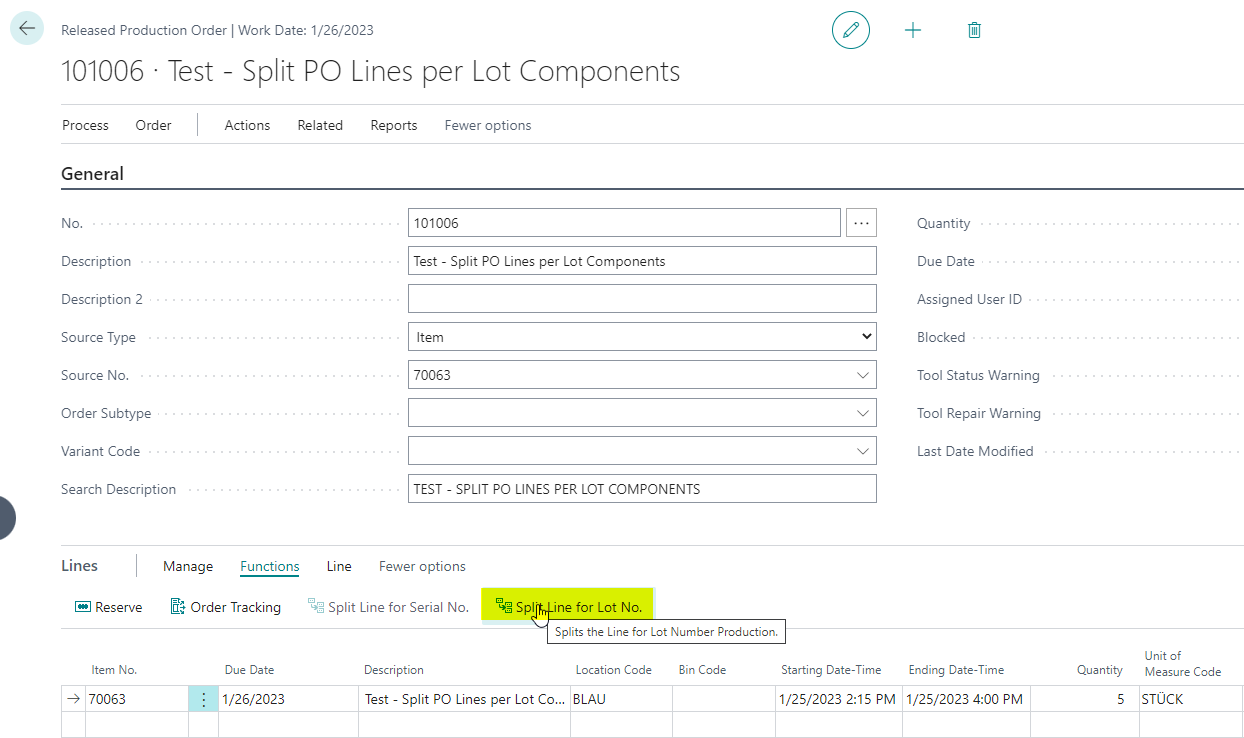

If you use one production order line in your production order there is moments where you might need to assigne a new Lot No. in the mittle of one production order. If this is the case you can achive better analytics creating a new Production Order Line for each different Output Lot No. This can be done manually or by using the function "Split Line for Lot No." that was introduced in order to make things easier for you.

While Splitting, Routing, Components, Reservation, Picking and Item Tracking Information will be taken into account

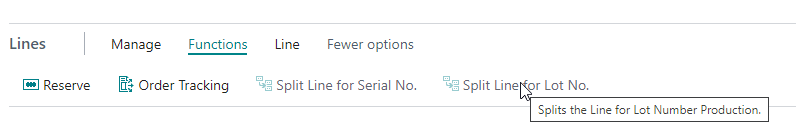

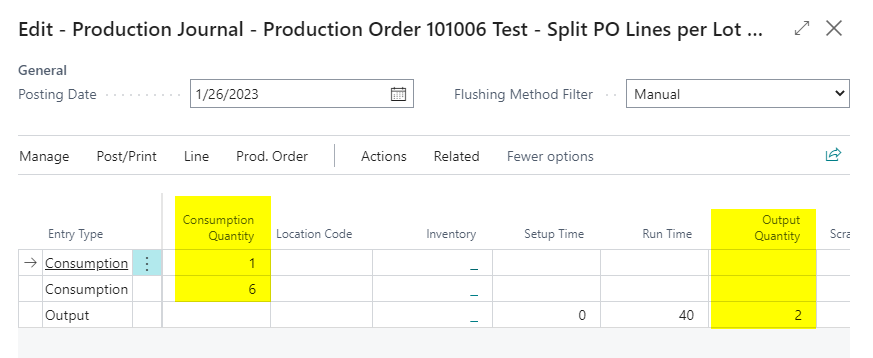

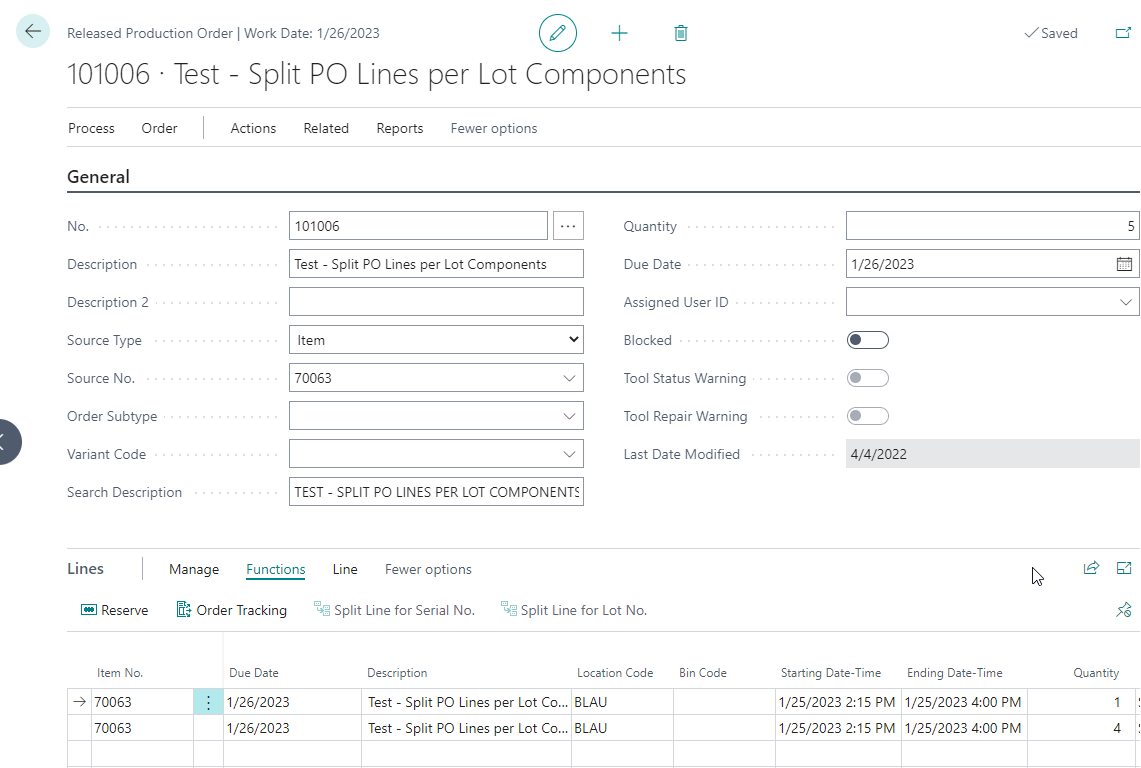

Now that all settings are done it is time to use the split feature. You will notice that the function ""Split Line for Lot No." is not available at first. This is only available after posting a partial production output.

Eventually after posting production output you will have to refresh page using F5 that you can actually use the function "Split Line fot Lot No."

After splitting lines for Lot No. you will see that a new line with the unfinished quantity was created. You can now repeat the process and post the corresponding output quantity for the second line having into account another Lot No. for components or your output.

Routing, Components, Reservation, Picking and Item Tracking Information will be transfered to the new line