Production of each product is described with its Production Bill of Material and production steps named Production Routing. Routing describes sequence (serial, parallel or combination of both) of required steps named Operations. Each Operation is performed by/in its primary capacity. Standard BC supports description of primary capacities with Machine Centers and Work Centers.

There are often operations where also alternative capacities are required to perform operation. Personnel and Tools are those alternative capacities in most cases. Sometimes Tools or Personnel capacities availability is production bottleneck (production capacity constraint), so it must be carefully planned. Standard BC functionality offers a possibility to add rough description of required Personnel, Tools and Quality Measures for each Operation, but there is no accurate parameters available to describe those requirements in a way appropriate for production planning.

Personell and Tools Planning and Posting functionality brings ability to: - describe each Operation with quantified parameters of required Personnel and Tools to perform Operation. - describe Personnel and Tools requirements on detailed (specify requirements for each instance) or more rough level (quantities only). - define required Properties / Skills for each Personnel and Tools instance involved in Operation. - link each Operation Tool or Person with a Resource and a capacity center (Machine or Work Center). - export Production Routings, including Personnel and Tools requirements, for external scheduling and import scheduled results back (will be added in Wave 2). - post Tools and Personnel capacity costs and contribute to more accurate product costing (will be added in Wave 2).

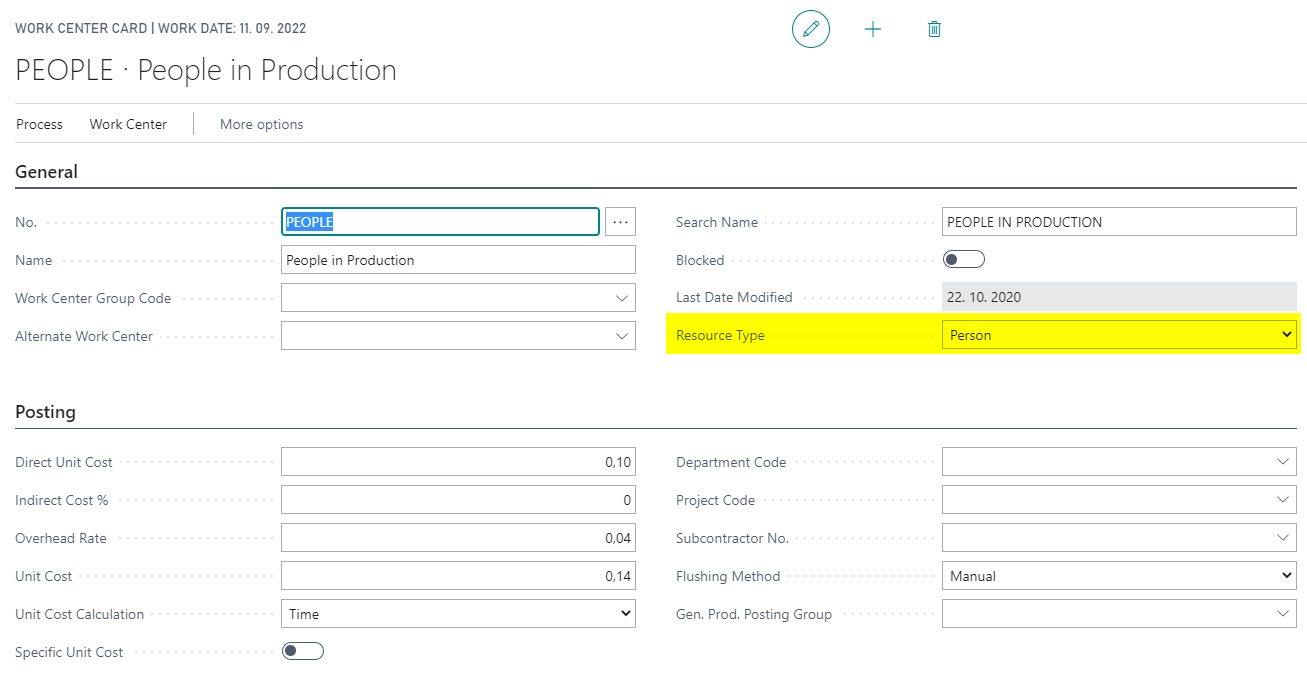

Special Machine Centers and Work Centers can be prepared to represent Personnel and Tools manufacturing capacities. New field "Resource Type" has been added to Machine and Work Center to specify which type of resources it represents: - Person - represents Personnel - Machine - represents Tools

Machine and Work Centers respresenting Personnel and Tools can have Unit Costs defined as any other Machine or Work Centers.

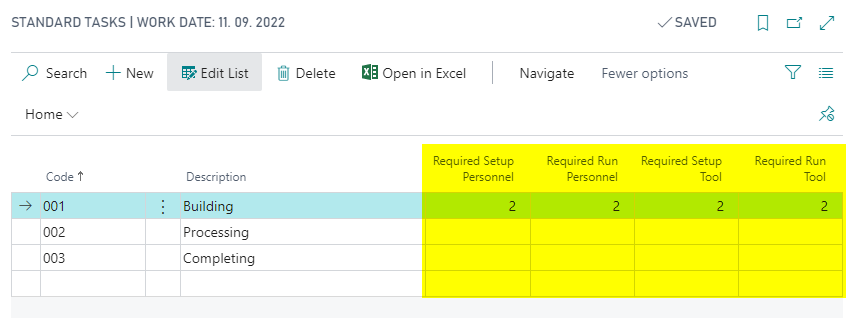

[Standard tasks] (https://docs.microsoft.com/en-us/dynamics365/business-central/production-how-set-up-standard-routing-lines) simplifies the creation and maintenance of routings.

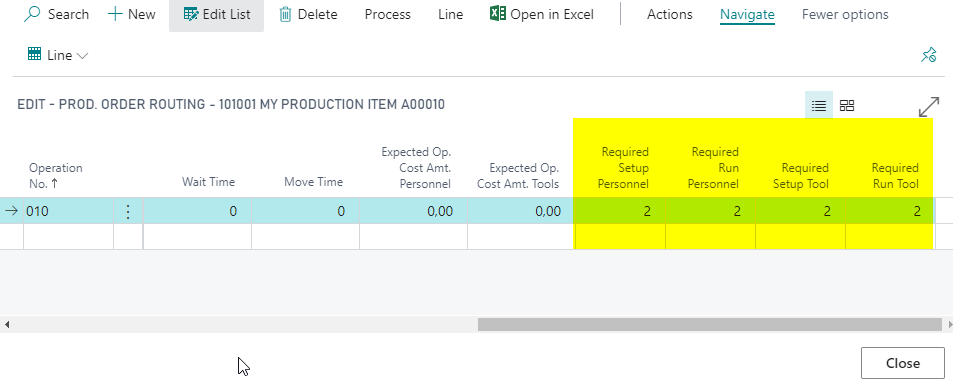

New fields are added to Standard Task record: - "Required Setup Personnel" - specifies number of people required for Operation Setup. - "Required Run Personnel" - specifies number of people required for Operation Run. - "Required Setup Tool" - specifies number of tools required for Operation Setup. - "Required Run Tool" - specifies number of tools required for Operation Run. Those fields need to be maintained manually at the moment, but it is planned that values will be automatically defaulted (based on subordinate records - Standard Task Personnel and Tools) in future releases and then user will stil have ability to update them.

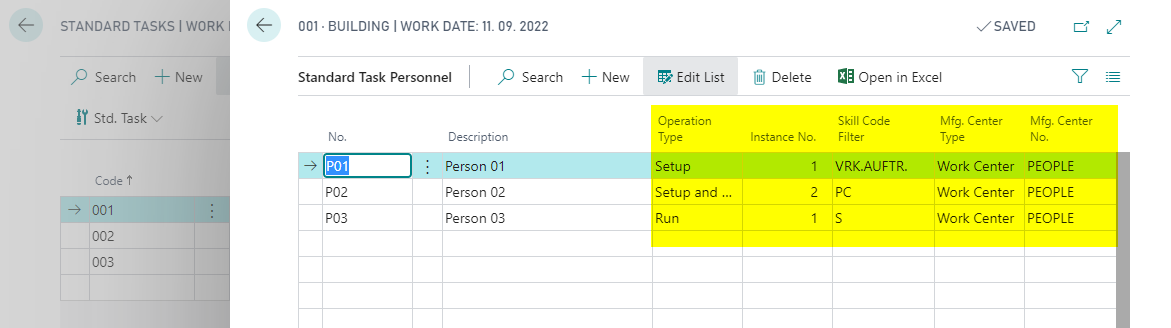

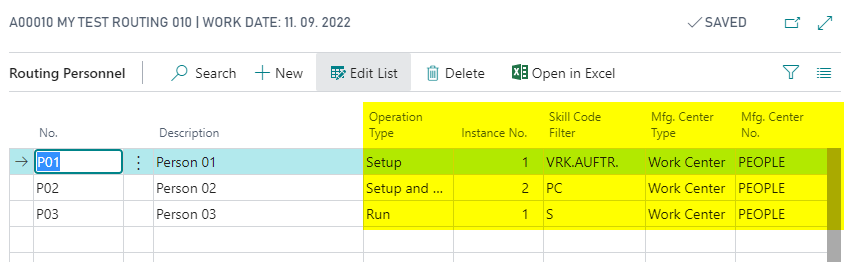

Standard Task Personnel and Tools bring ability to link Personnel and Tools with Standard Task.

New fields are added to Standard Task Personnel and Tools records: - "Operation Type" - specifies in which part of Operation Person or Tool will participate: - Setup - specifies that this Instance of Person or Tool will participate in Setup part of Operation only. - "Setup and Run" - specifies that this Instance of Person or Tool will participate in Setup and Run part of Operation. - Run - specifies that this Instance of Person or Tool will participate in Run part of Operation only. - "Instance No." - specifies Instance number of Person or Tool inside "Operation Type" (Setup or Run) - "Skill Code Filter" - specifies which Skill Person or Tool must have to be able to perform task. Only one Skill is allowed in current functionality. Skills are specified as Service Management Resource Skills. - "Mfg. Center Type" - specifies which manufacturing capacity type will be used for capacity costing and posting (Machine Center or Work Center). - "Mfg. Center No." - specifies which manufacturing capacity will be used for capacity costing and posting. Depends on selection in "Mfg. Center Type".

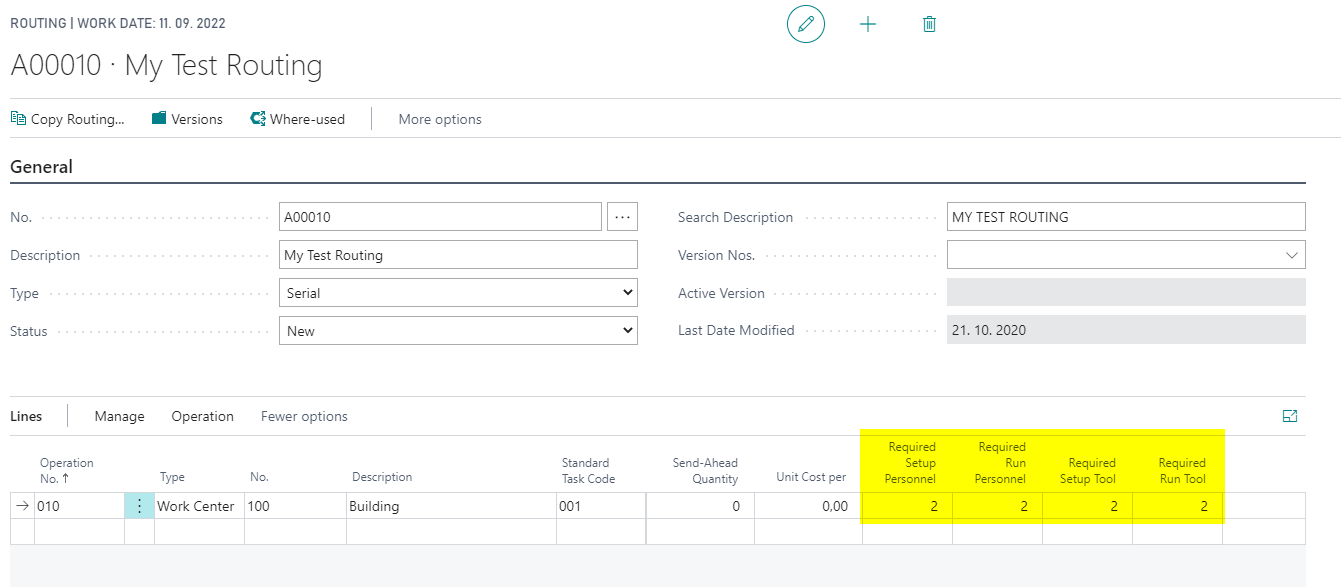

Manufacturing companies use routings to visualize and direct the manufacturing process. Routing is the basis of process scheduling, capacity scheduling, scheduled assignment of material needs, and manufacturing documents. Personell and Tools Planning and Posting functionality brings new fields and possibilities to Routing definition.

Fields which were added to Standard Task are also added added to Routing Line. Fields which were added to Standard Task Personnel and Tools are also added to Routing Line Personnel and Tools. When user enters "Standard Task Code" on "Routing Line" those fields are transferred.

Field values can be manually changed after being populated with defaults from Standard Task.

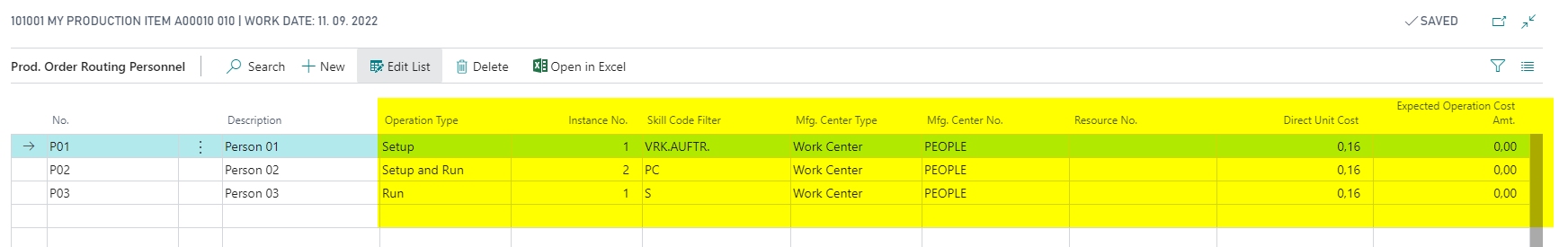

When Production Order is Refreshed, Production BOM details are written to "Production Order Components" and to-produce Item Routings to "Production Order Routing". New fields added with Personell and Tools Planning and Posting functionality are transferred to new fields added to "Prodcution Order Routing Line" and its Personnel and Tools subline.

"Prodcution Order Routing Line Personnel" and Tools subpage

Additional fields in comparison to "Routing Line Personell" and Tools are added: - "Direct Unit Cost" - specifies "Unit Cost" from selected "Mfg. Center No." which represents a Person or Tool. - "Expected Operation Cost Amt." - specifies total expected cost amount based on "Direct Unit Cost" and time required to perform Setup and Run operations for complete planned quantity. - "Resource No." - specifies a Resource which is planned to perform specific task for the operation. "Resource No." can be picked manually or specified by external Adavanced Planning and Scheduling (APS) engine.