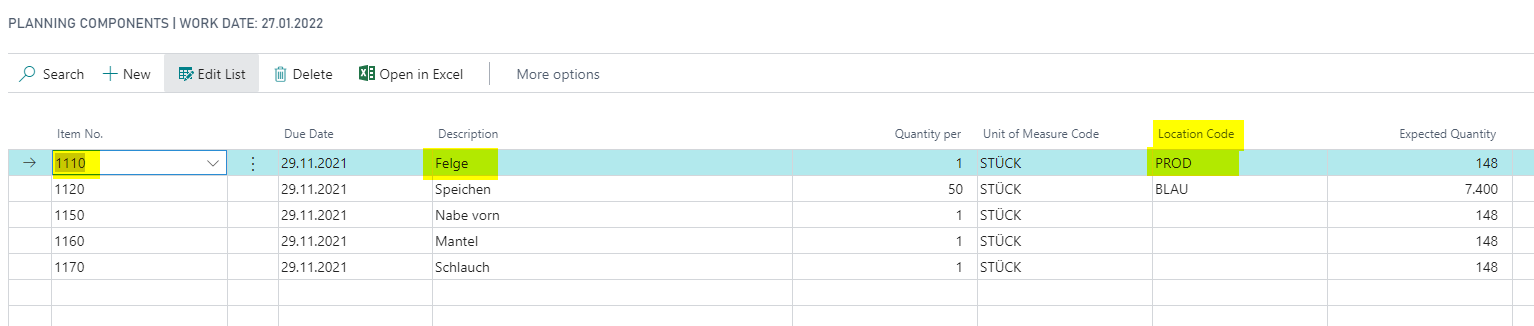

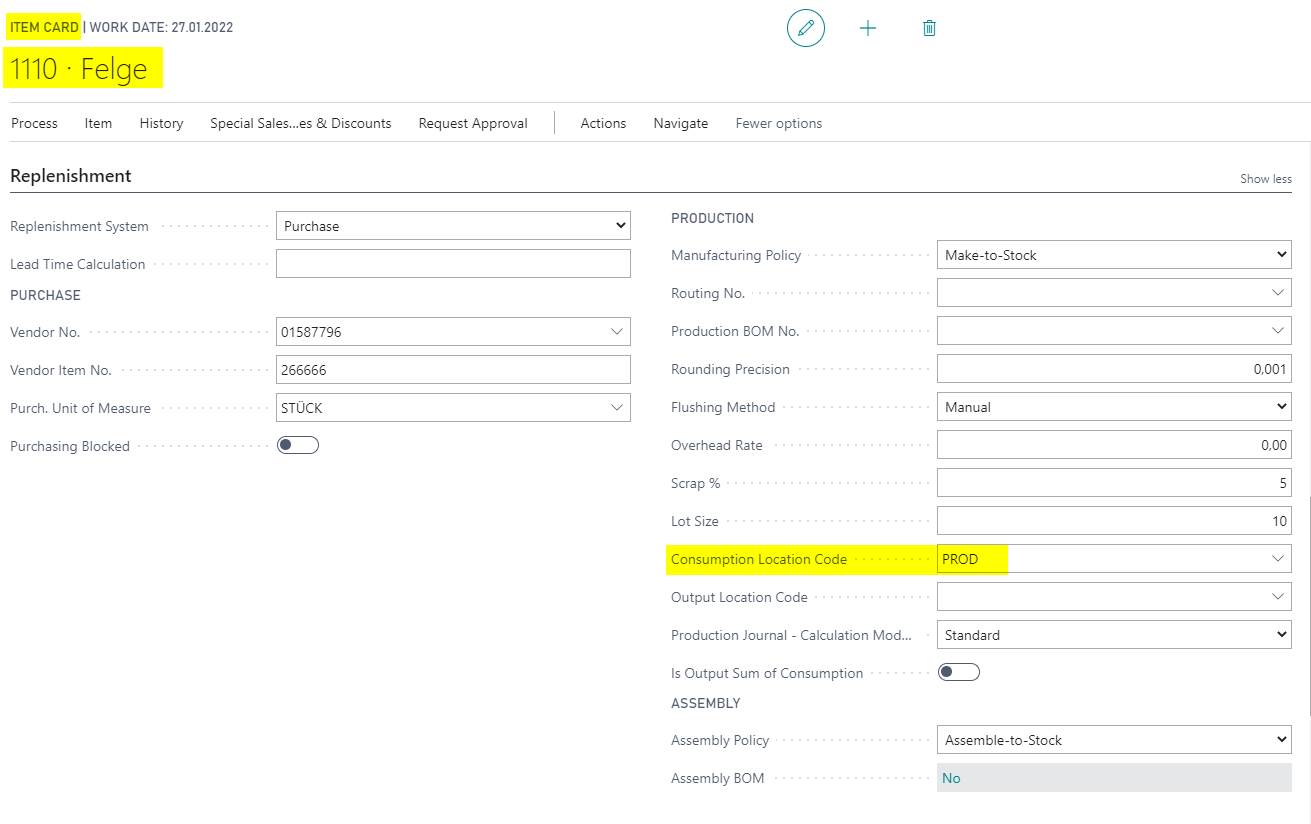

Transfer of Location Codes from Item to BOM and Production Journal functionality enables that Consumption Location Code is transferred from Item Card to Production BOM Lines and from there to Location code in Production Journal Lines.

It also enables that Output Location Code is transferred from Item Card to Production Journal Lines. Both fields are also used for planning.

In standard solution location codes on Production BOM and on Production Journal needs to be entered manually, which is time consuming and offers more opportunities for mistakes. Location code defulting therefore reduce user caused mistakes and improves user experience due to a fact that certain data is provided automatically and there is no need for manual entry, but there still exists possibility to manually change location code if required.

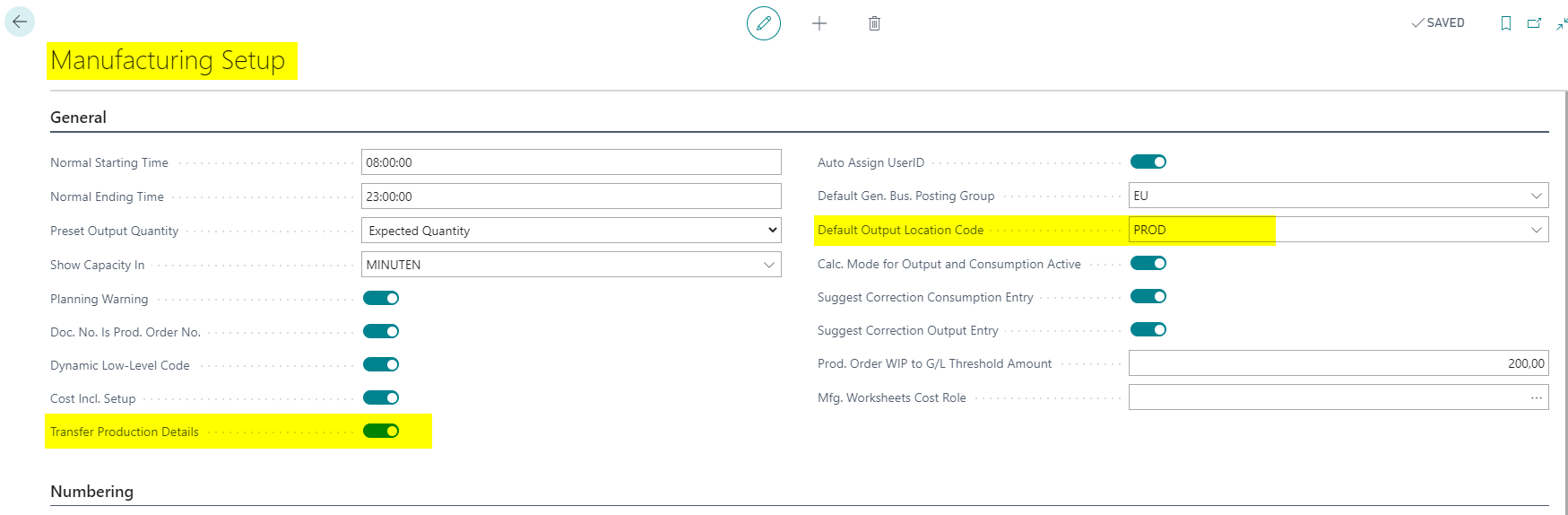

To enable prepayments functionality you need to set some fields on the table Manufacturing Setup.

Open Manufacturing Setup.

Set field Transfer Production Details on General FastTab to enable functionality.

Set field "Def. Output Location Code"

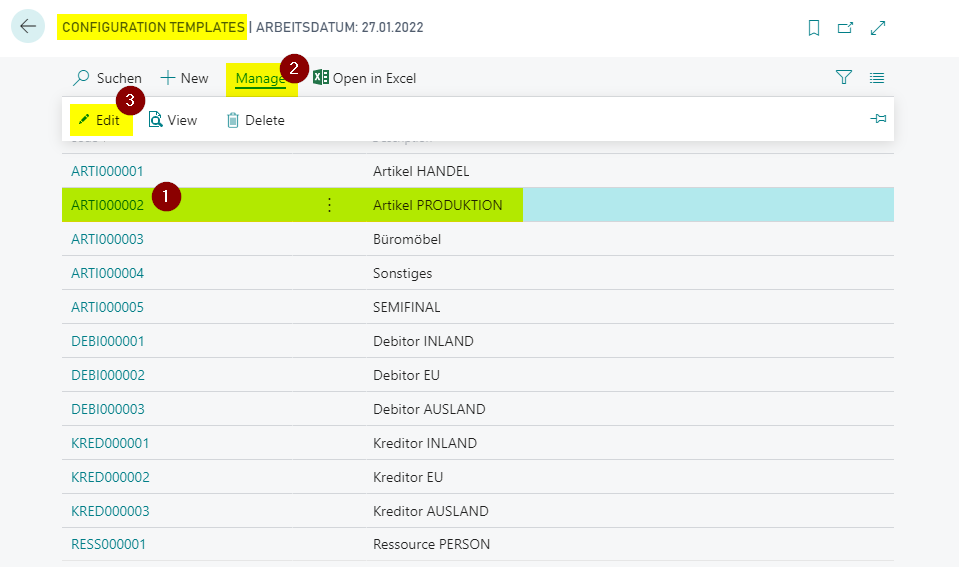

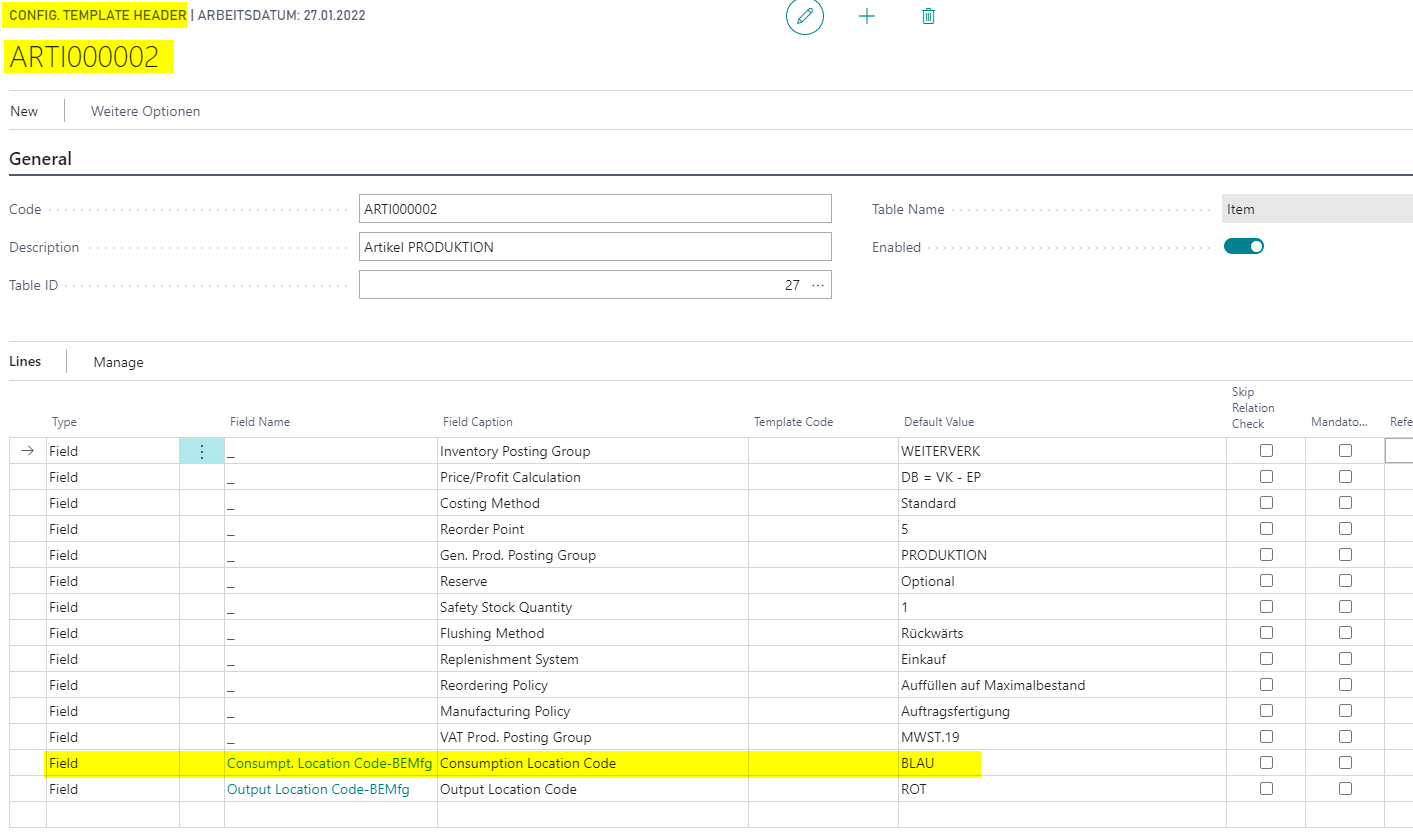

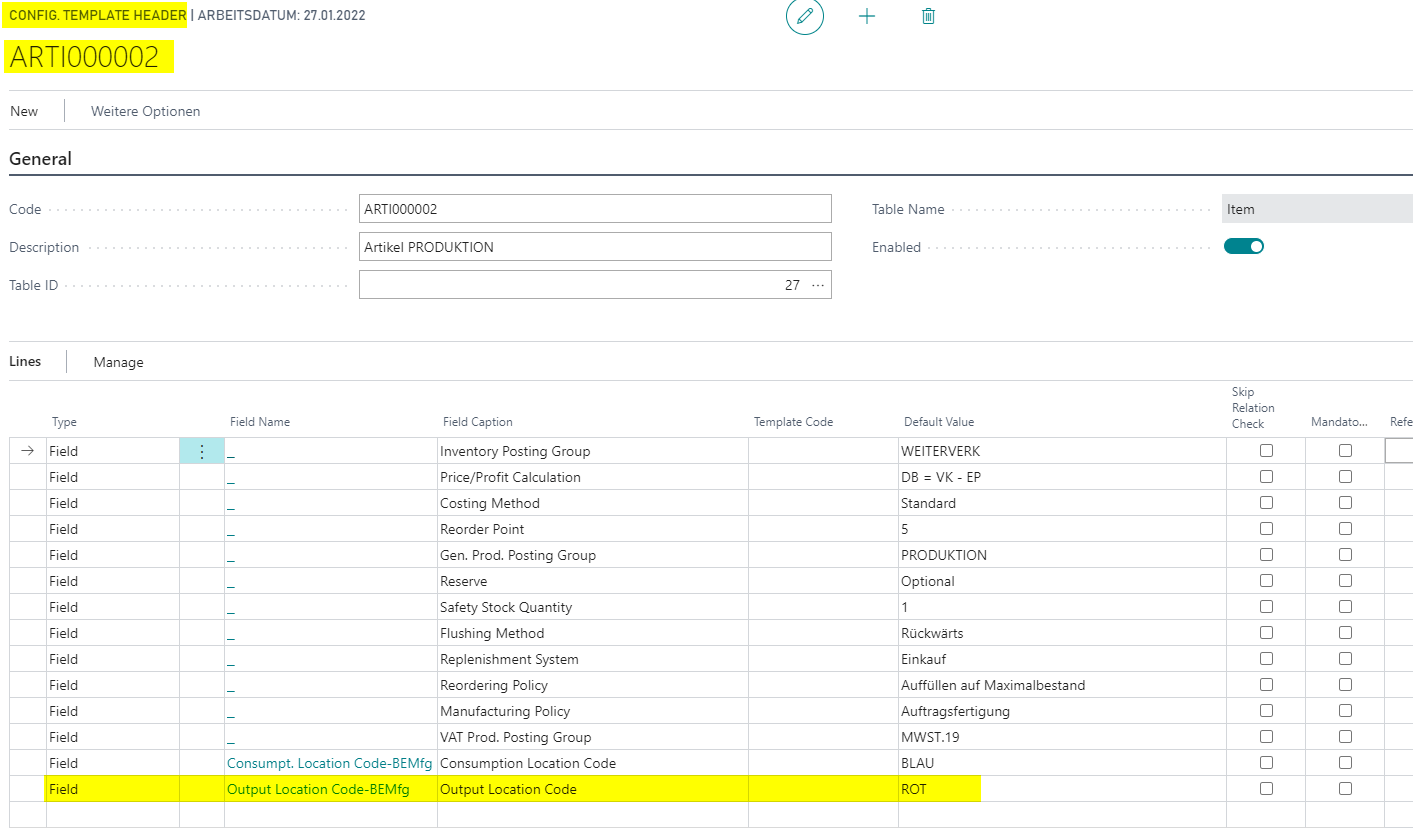

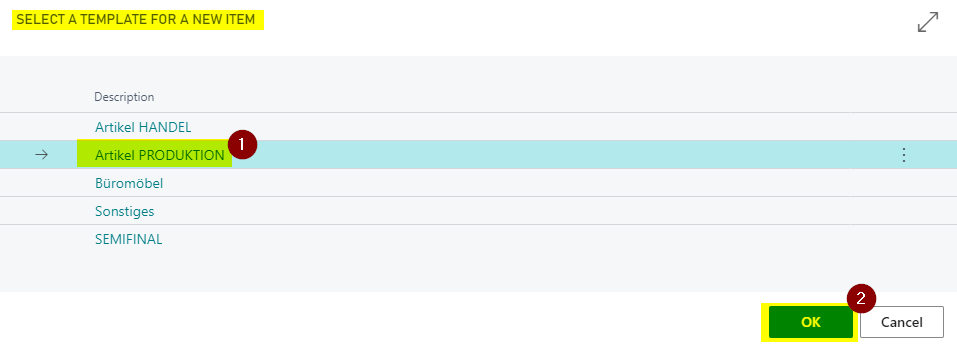

You can define default setup on Configuration Templates for the Item Template that can be used when creating new items.

Open Configuration Templates.

Choose the Item Template that have to be defined.

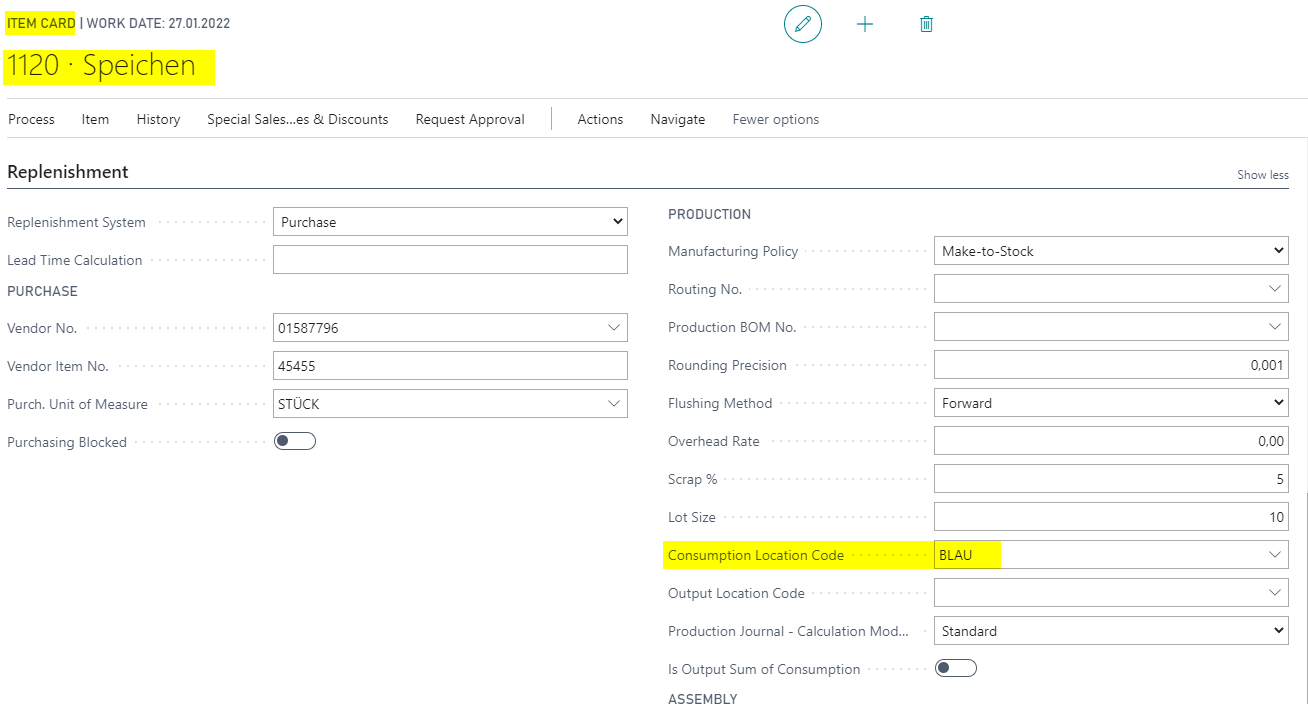

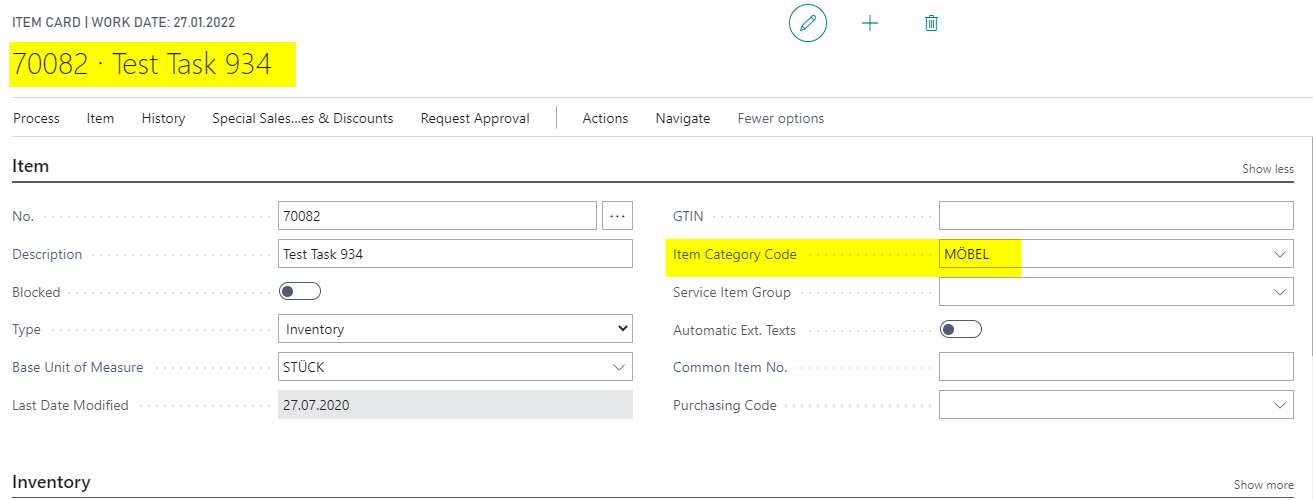

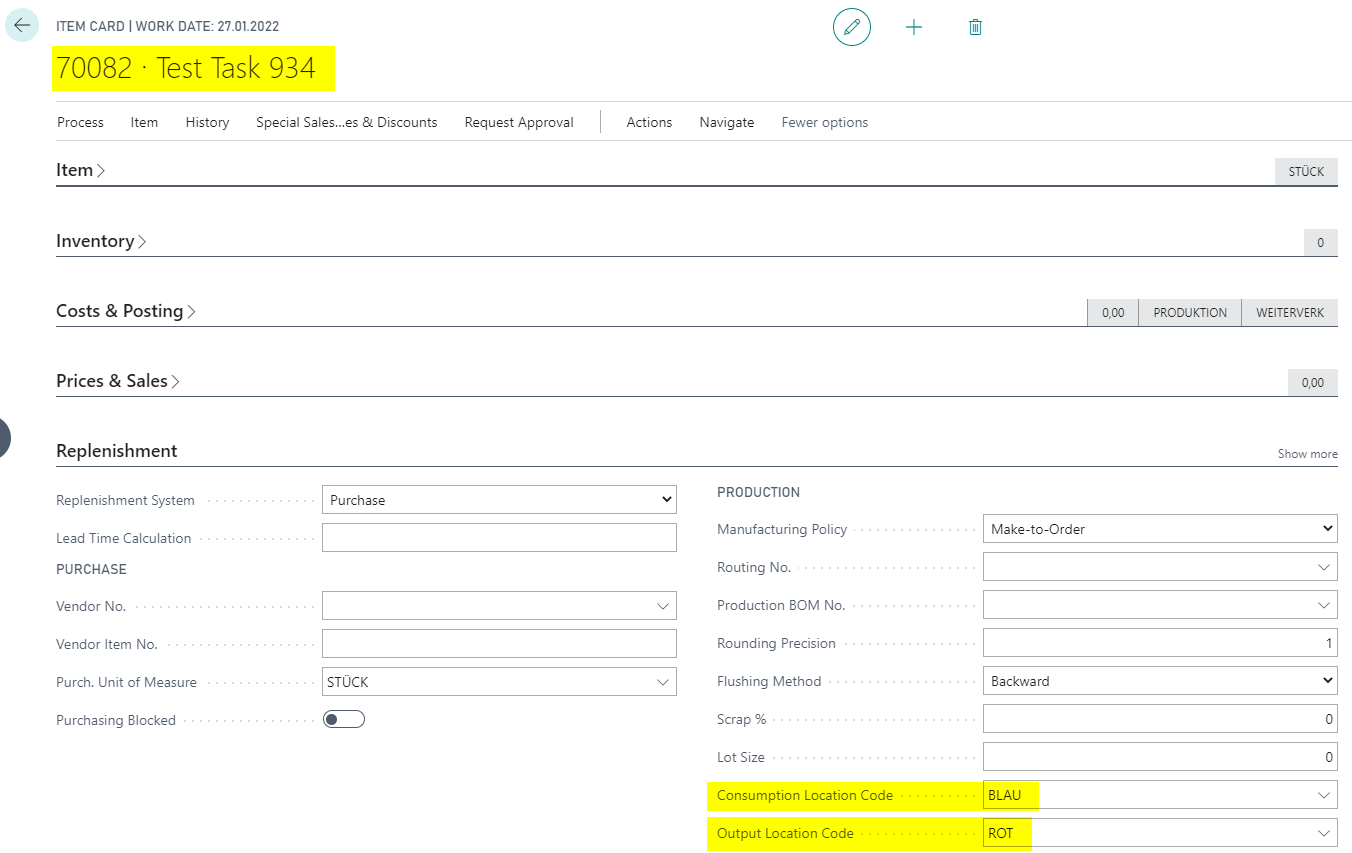

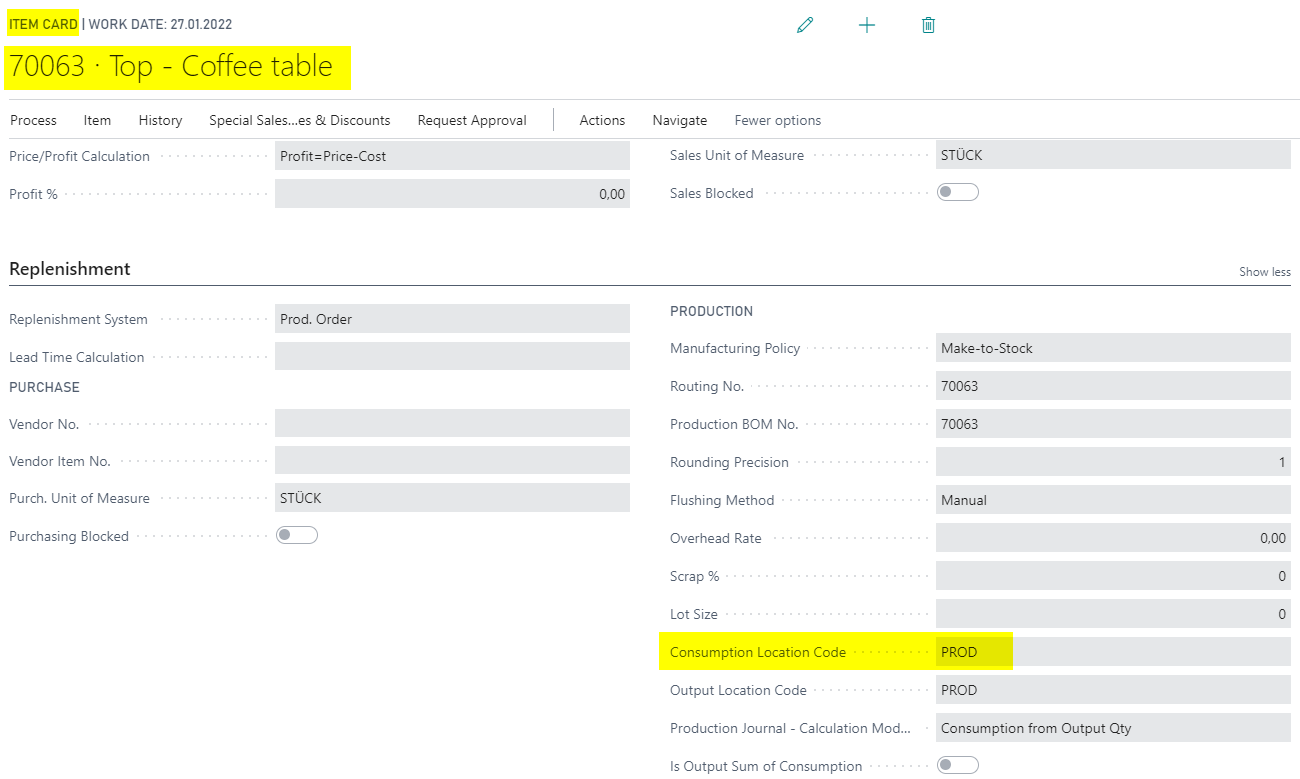

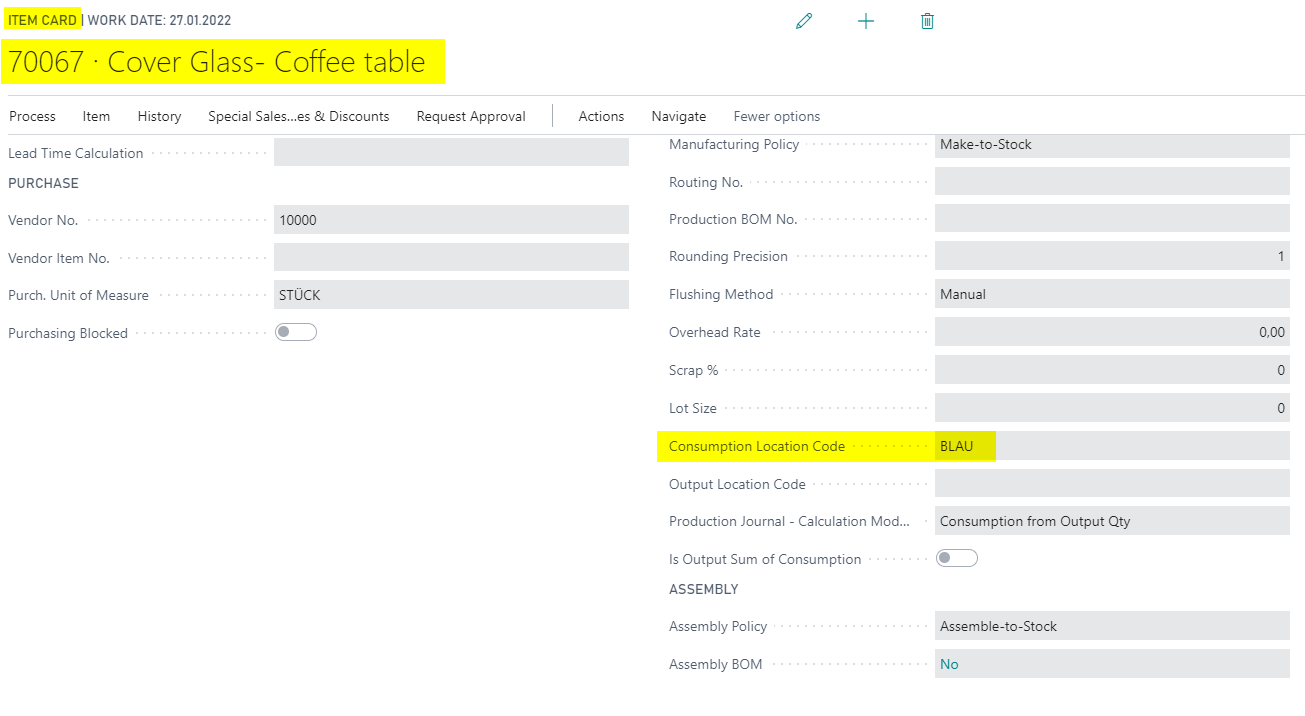

Field Consumption Location Code on Replenishment FastTab is transferred from Item Template. The field is used when an item is transferred to Production BOM lines or Production Journal.

Field Output Location Code on Replenishment FastTab is transferred from Item Template. The field is used when an item is transferred to Production Journal.

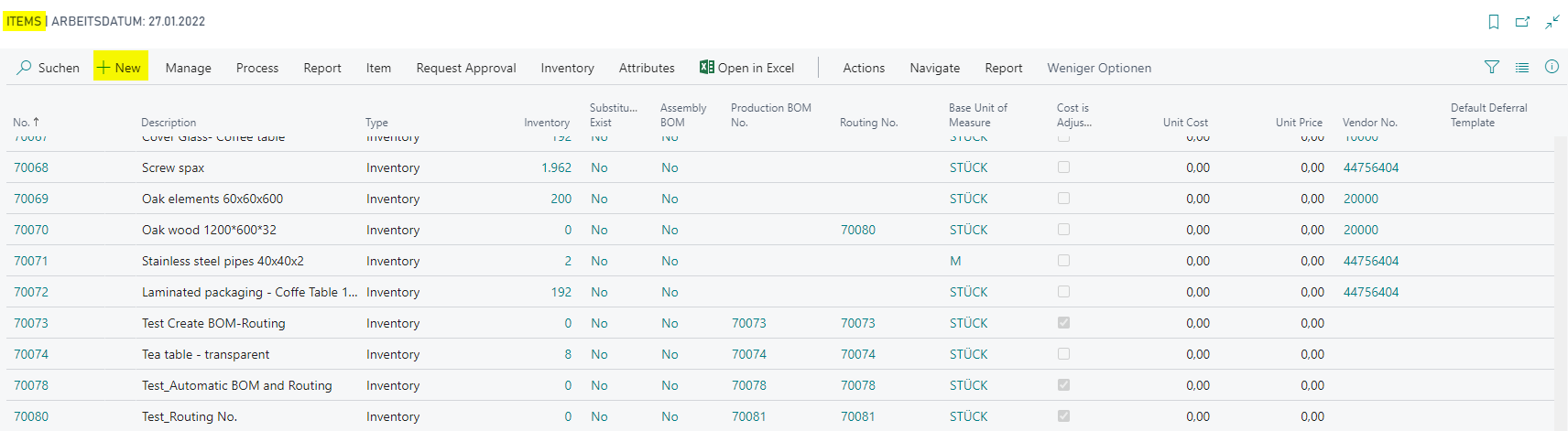

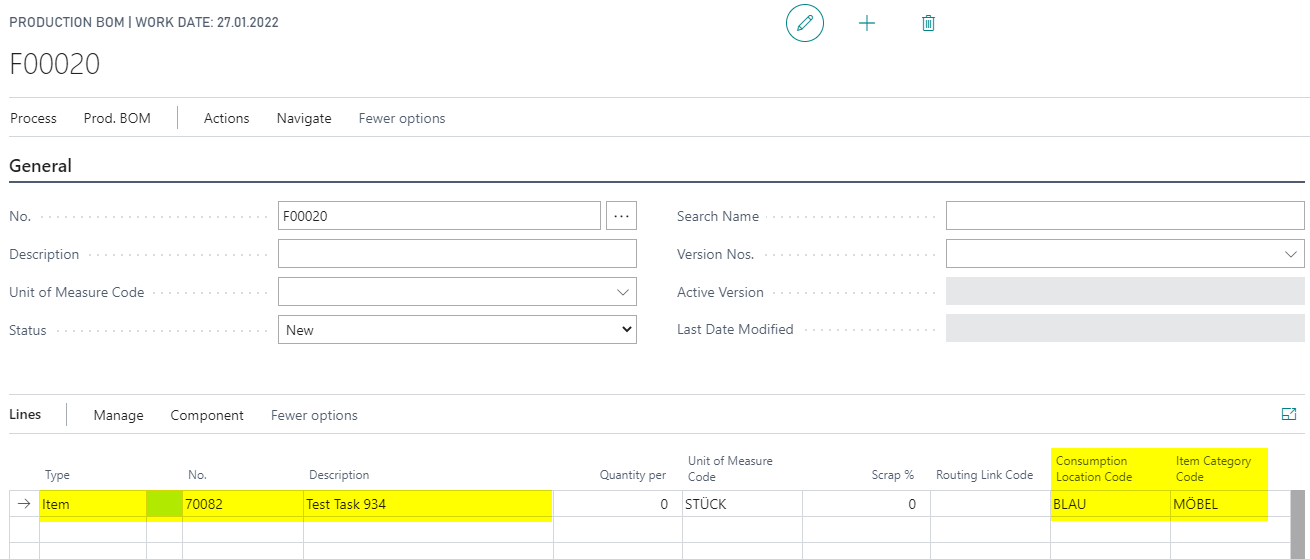

Open Production BOM.

Choose Type Item and enter Item No.

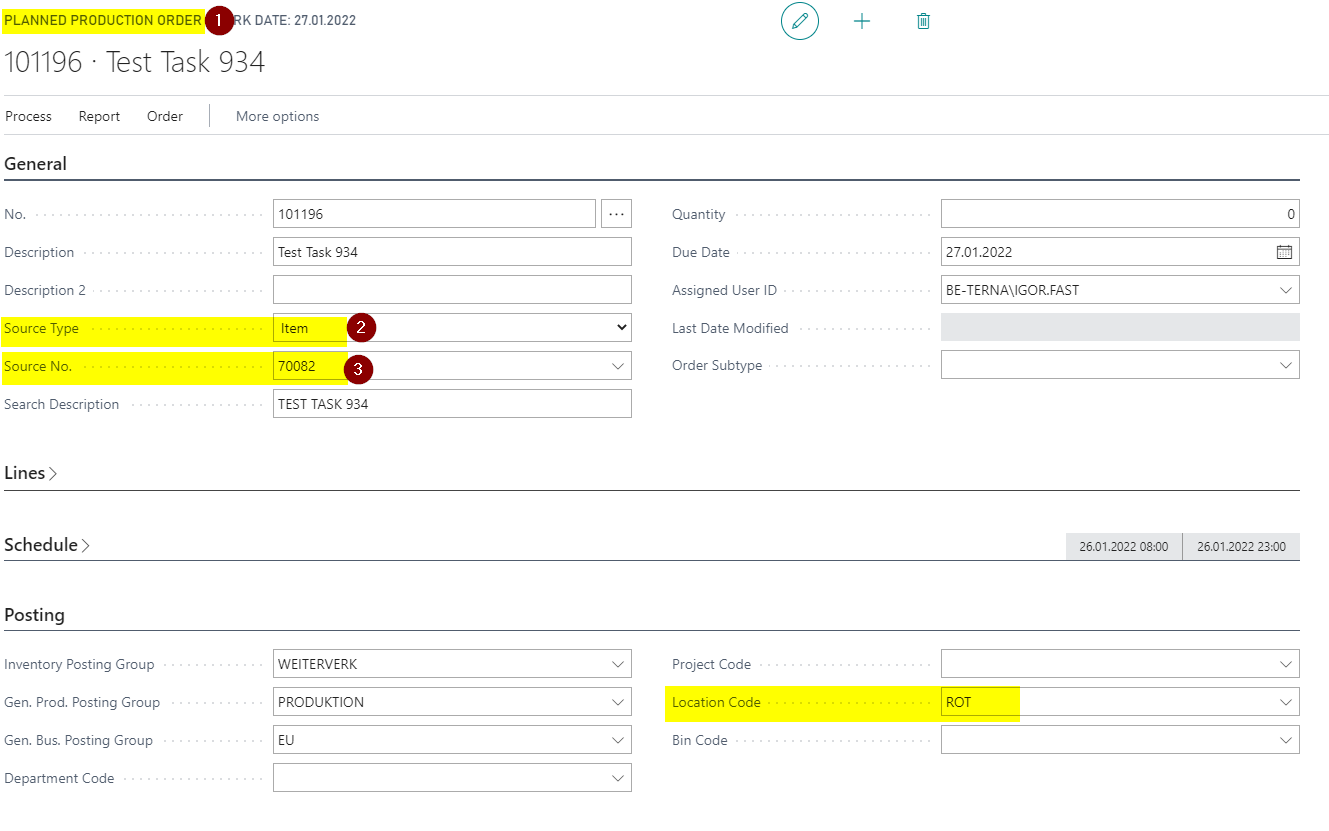

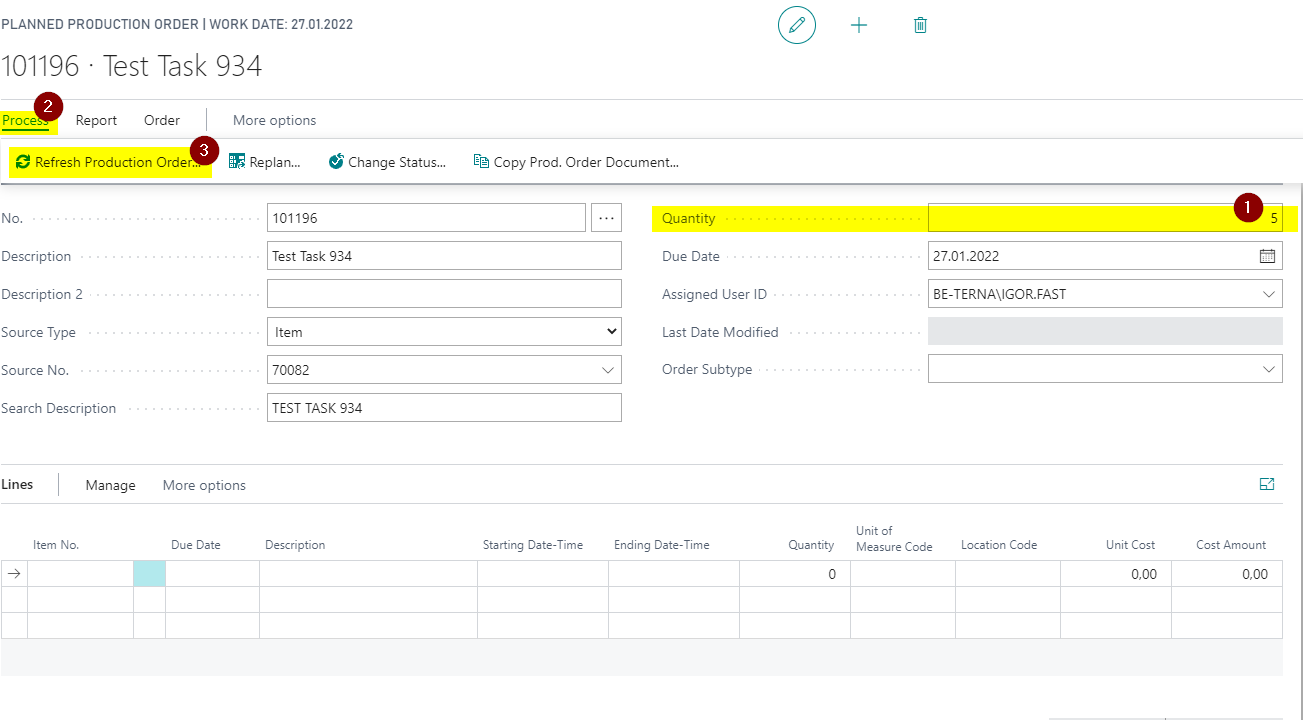

Open Production Order (of any Status: Simulated, Planned, Firm Planned, Released).

Choose Source Type: Item.

Choose Item No. in field Source No.

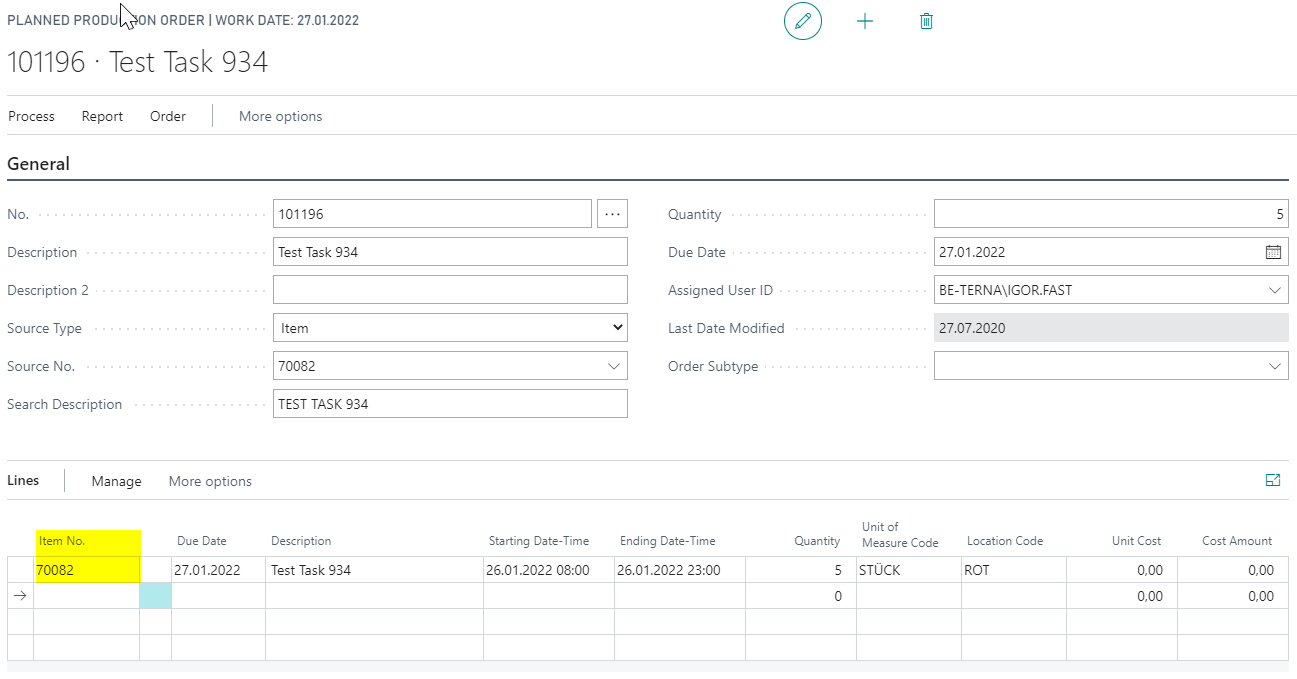

Field Location Code is transferred from the field Output Location Code on Item Card.

Enter Quantity.

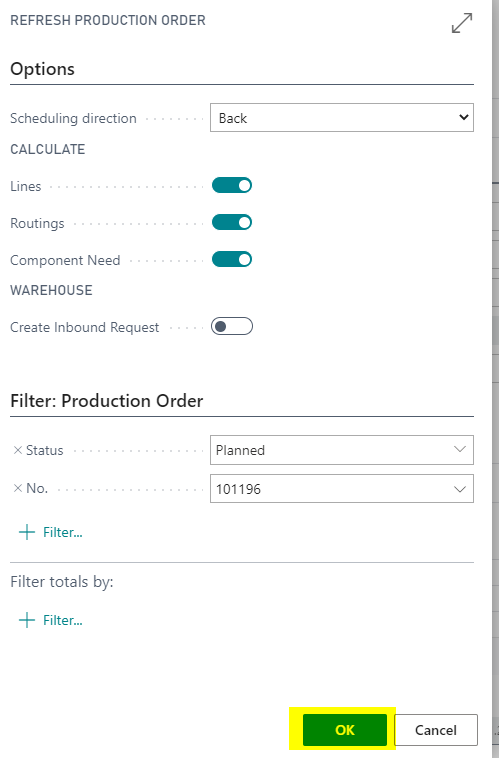

Choose button Refresh Production Order on Home Tab and choose button OK.

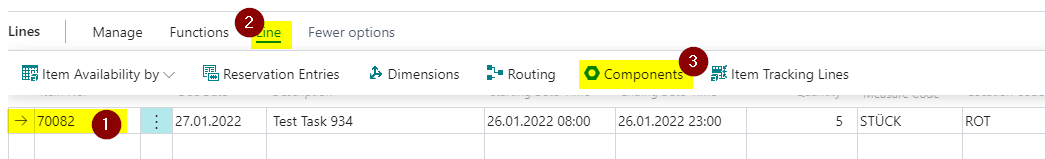

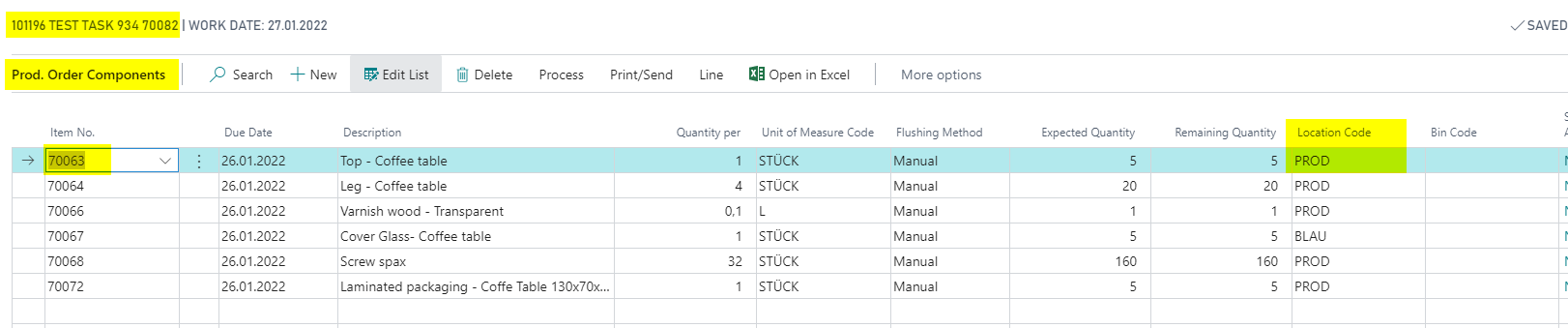

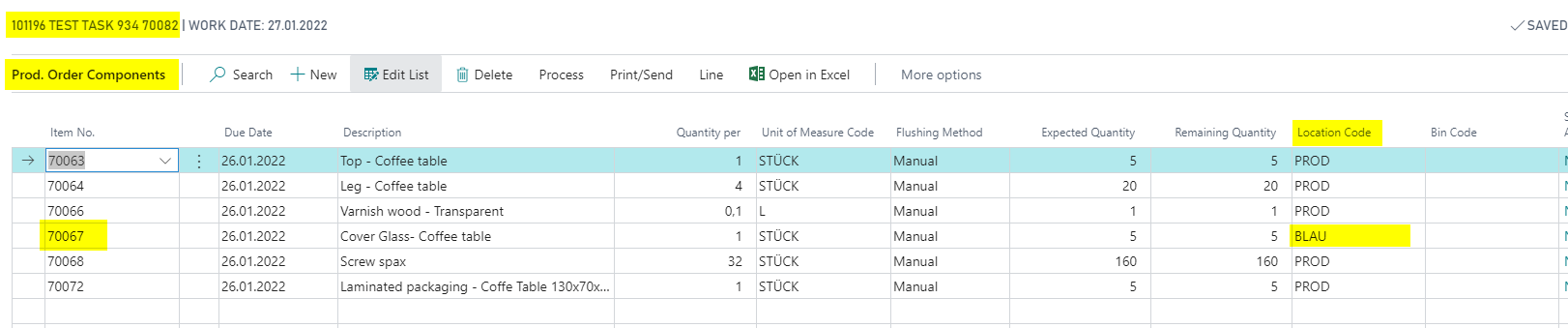

Open Production Order Components.

Choose Item No. Field, Location Code is populated with field Consumption Location Code from Item Card.

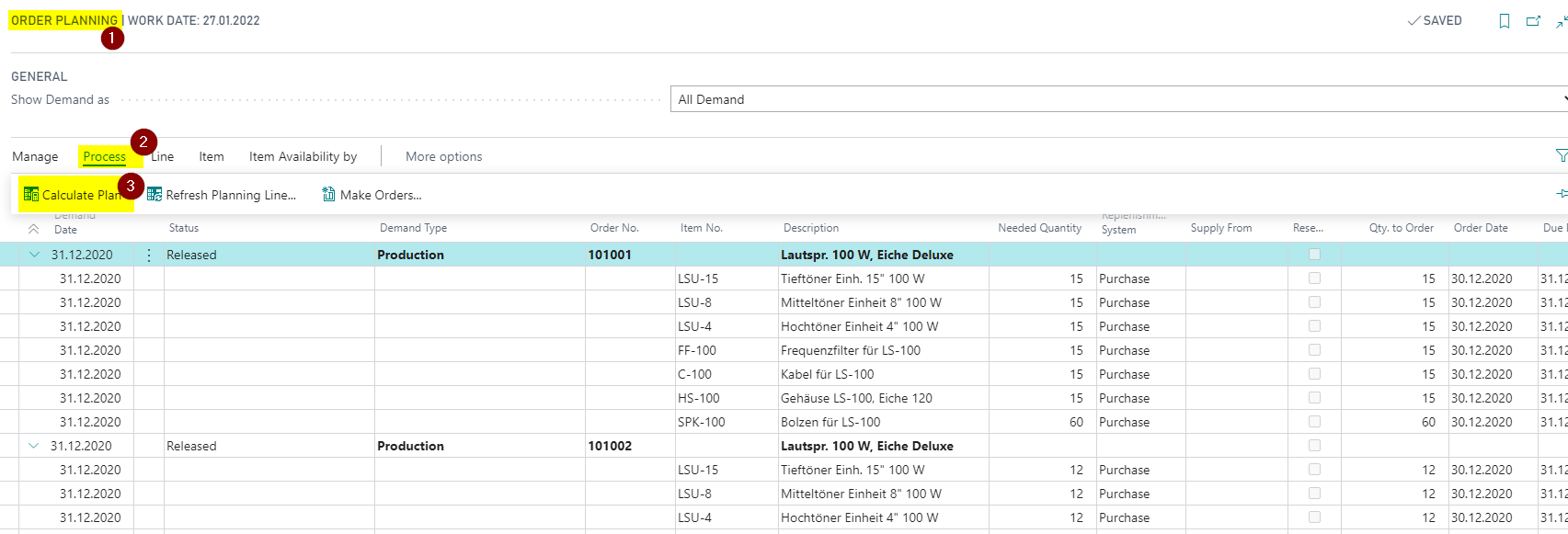

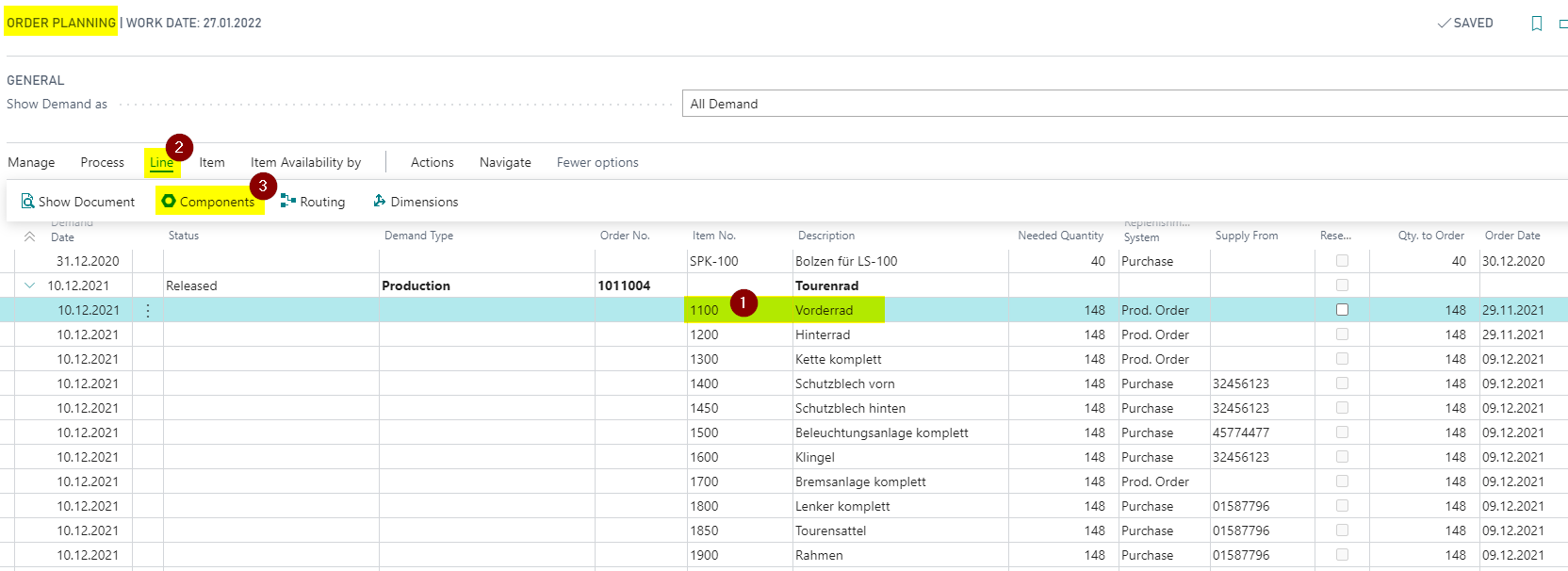

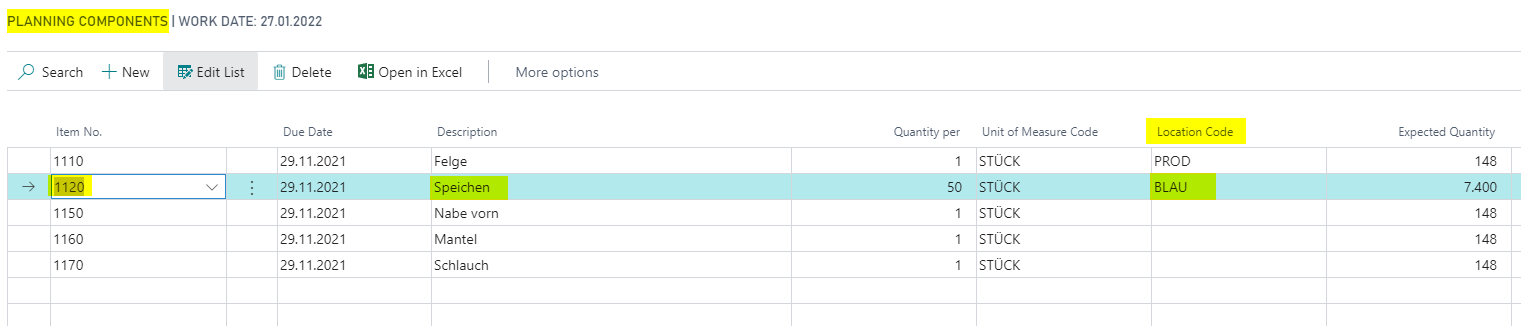

Open Order Planning.

Choose button Calculate Plan on Home Tab.