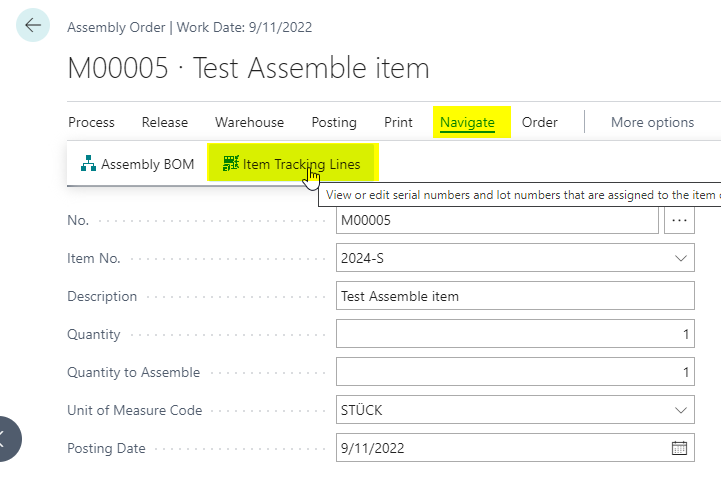

In some companies it is required that a lot, serial or package no. of a certain component transfers its item tracking information to the output item that is produced with a production order or assembly order.

Since in standard solution there is no feature to support this, we introduced a feature. This feature enables the automatic transfer of a lot, serial or package no. of a main component to the tracking information of the output item in a production or assembly order.

To enable this functionality, you will have to set up an item tracking code. This item tracking code will be used to configure main and output item.

![]()

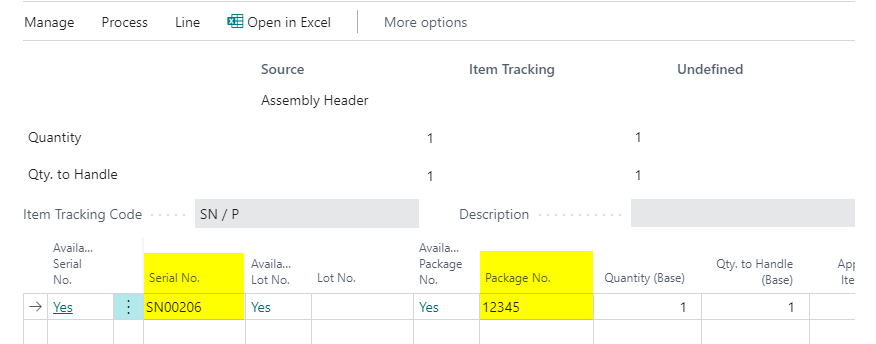

Select Option transfer from Main Component for field Automatic Lot No. from

![]()

Or Automatic Package No. From

Notice: For the configuration of the Item Tracking Code only the following combinations are allowed

The setup "Transfer from Main Component" for both of the fields "Package No." and "Lot No." in the same Item Tracking Code is at the moment not supported in this combination.

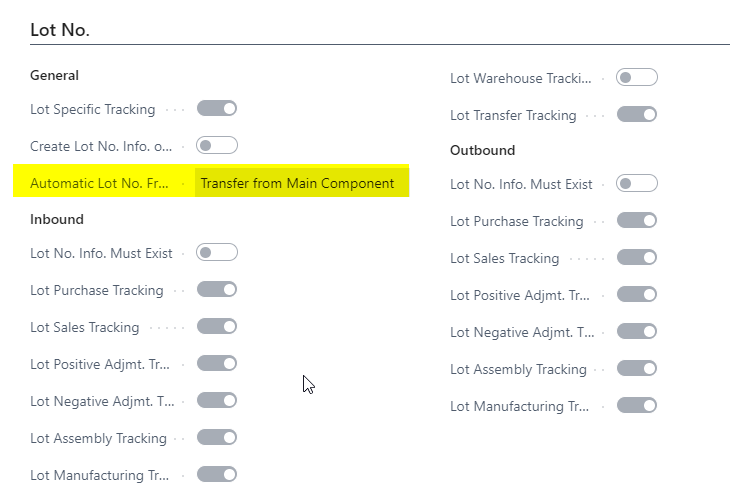

Now you have to configure your main item with the tracking code you chose

![]()

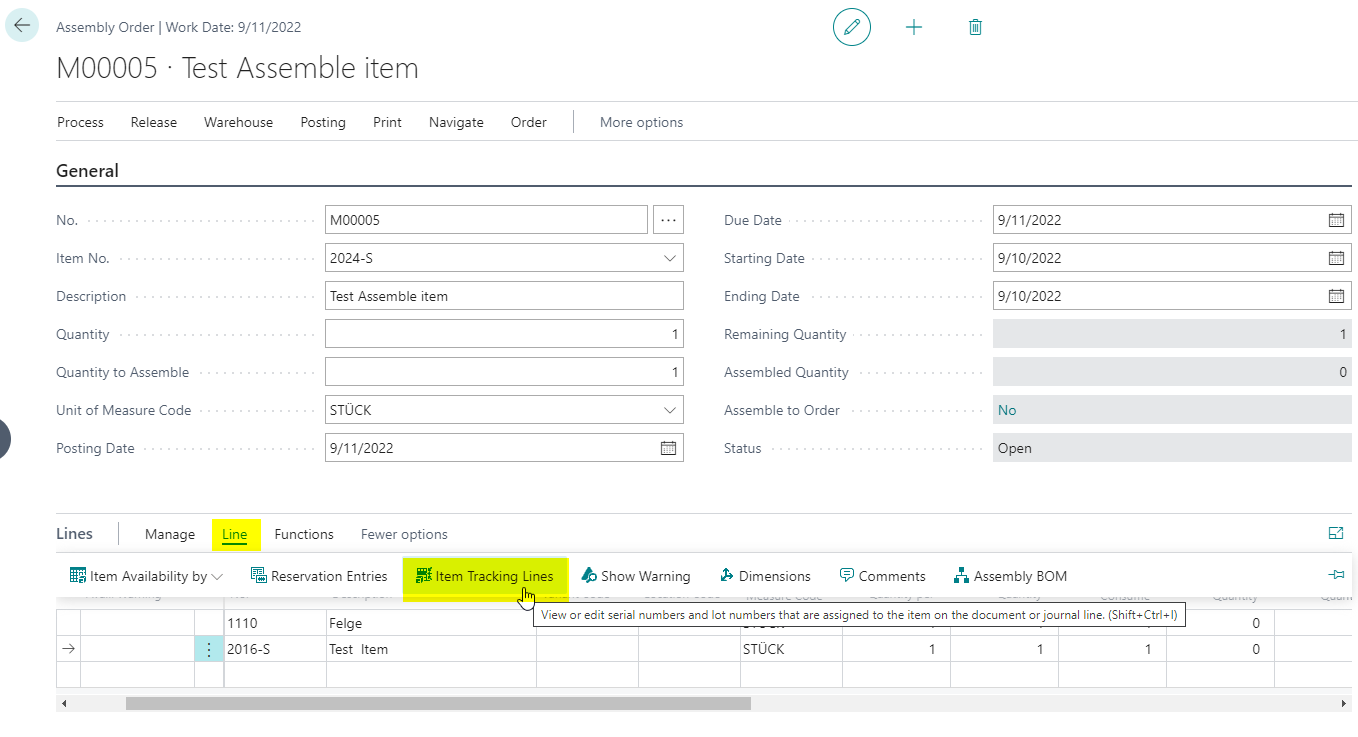

make sure you also set your item tracking code for your consumption item. In Addition to that it is necessary to mark one component of your Production BOM or Assembly BOM as main item from which the tracking information should be transferred to the output item

![]()

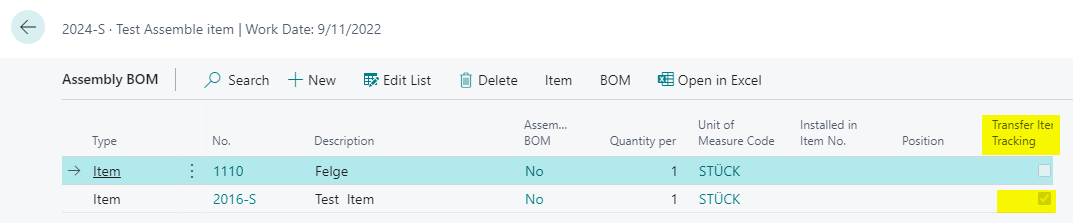

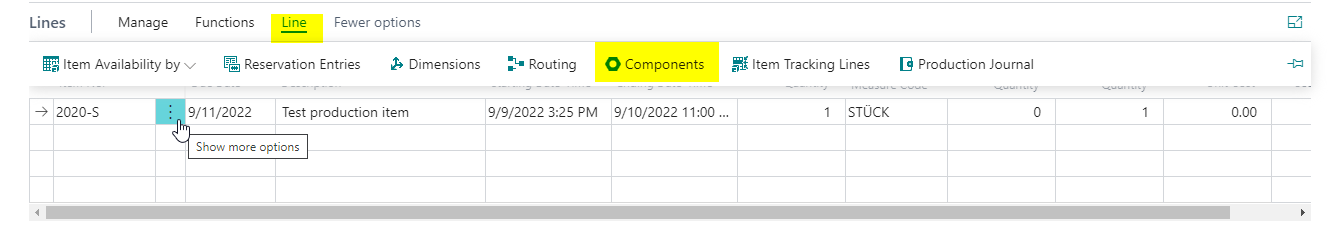

The transfer of tracking information begins after consumption is posted

Open Consumption Journal and select the production order

Create a new line for the created production order in the consumption journals

Post consumption journals line

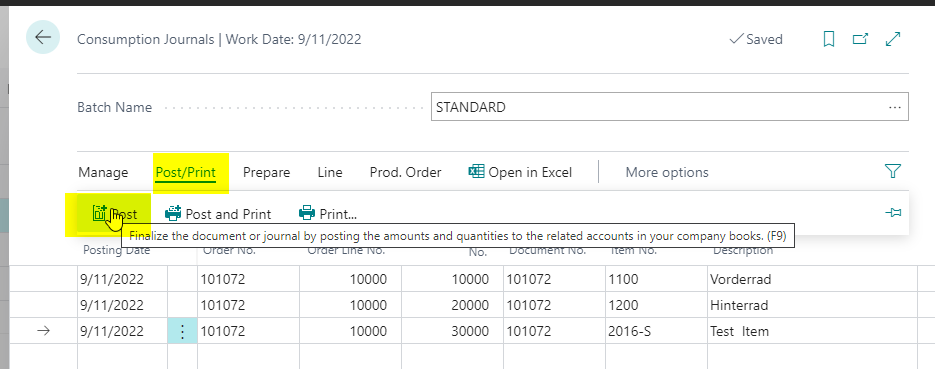

Go back to your production order and check item tracking lines of output item

![]()

Select the main item and open Item Tracking Lines

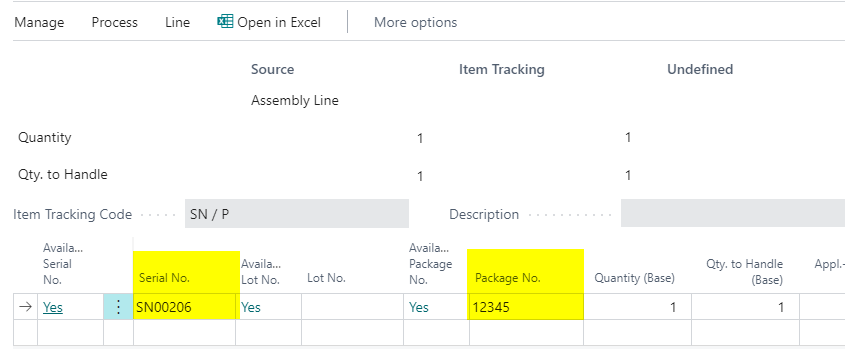

Select an entry for the component

To transfer item tracking information into the output item you must activate the validate trigger in the file Quantity to Consume.

Finally, you may want to check if tracking information was transferred to the output item