Production Order Final Costing Report

BUSINESS VALUE / REQUIREMENT

Ability to control and properly report production cost is one of the crucial things in manufacturing. When a product is produced with multi-level production orders it is hard to recognize proper costing structure, eventhough all information is available.

Final Costing report gathers costs through multi-level production orders and reports costs in a structure which is understandable to business users.

Report presents and explains complete cost structure also for complex multi-level produced products.

Final costing report brings following information:

- Detail quantity and costing information for all production orders involved in production of monitored product.

- Comparison between planned and actual costs - for each level and production order involved

- Accumulated material costs divided from capacity costs

- Accumulated costs per production order and its level (where monitored product represents level 0).

Producton Order - Final Costing Report

-

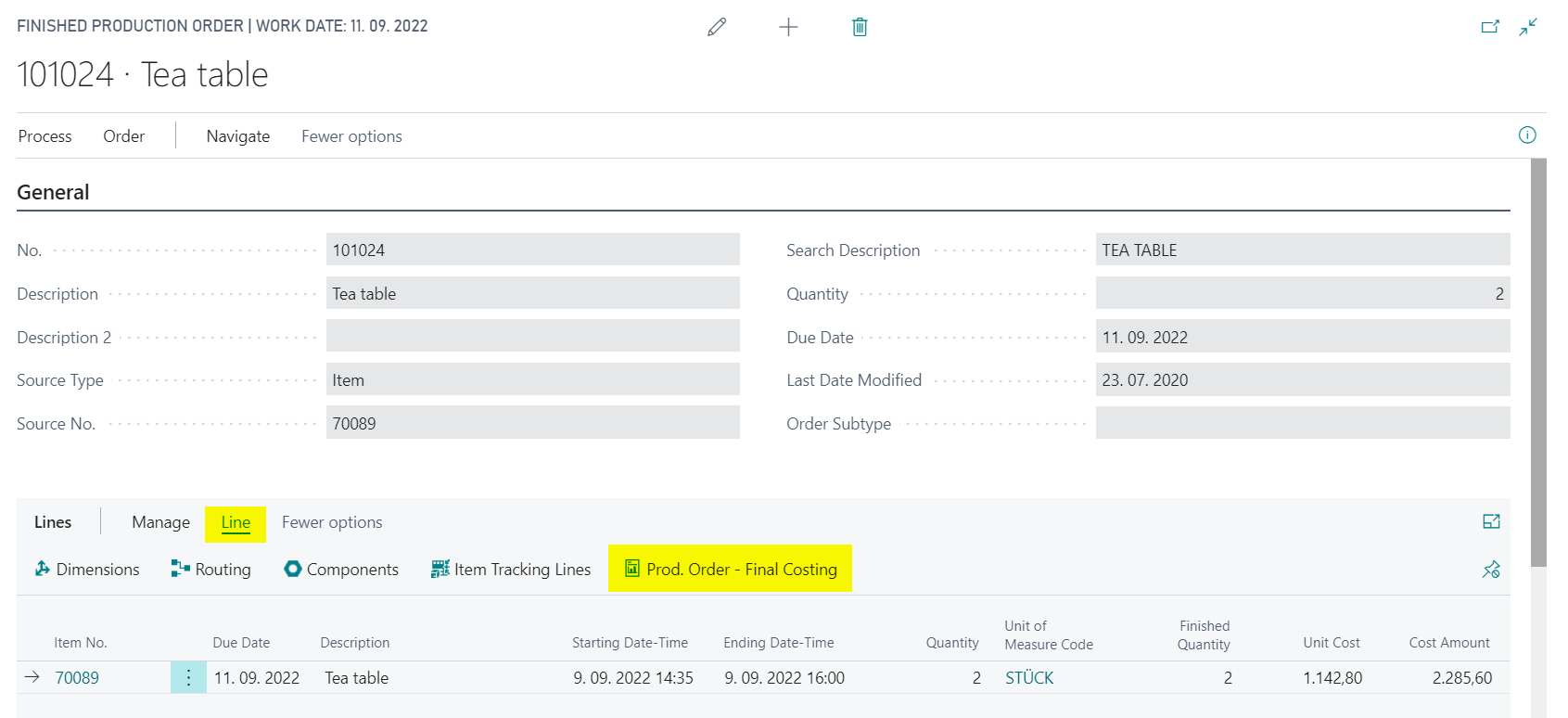

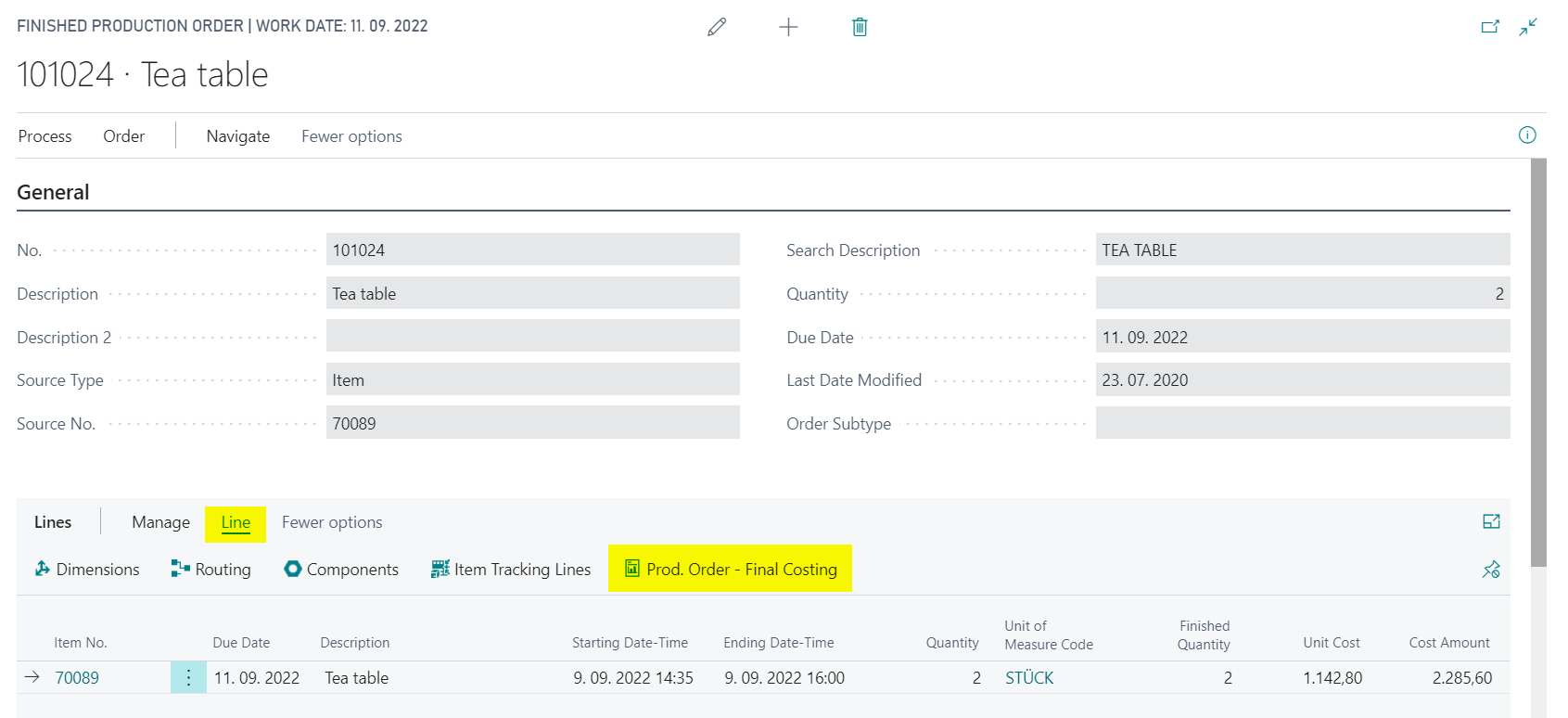

Open Finished Production Order Card with an Item which shall be analyzed.

-

Select Production Order Line and puch a button Line | "Prod. Order - Final Costing".

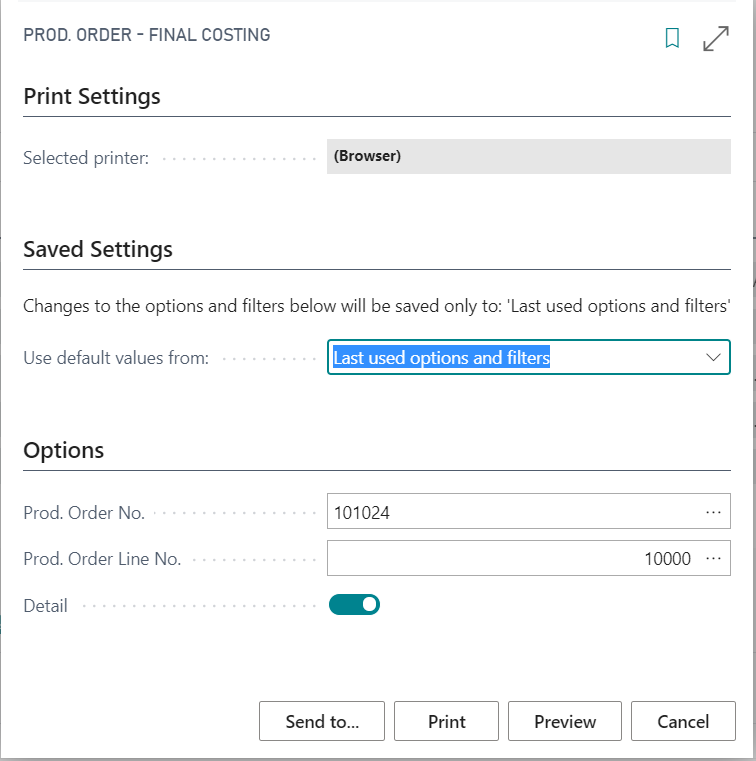

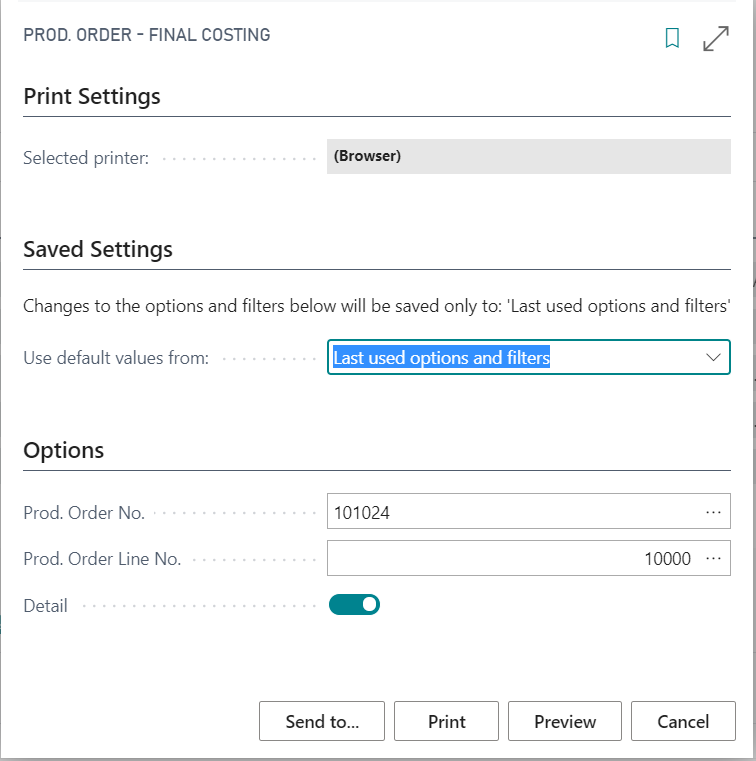

- Report Request page is shown. Define if report details shall be shown. If Detail is activated, report will present detailed analysis for each production order included in production of monitored product. Otherwise only a summary page will be presented.

Push Print or Preview button.

- Report is presented.

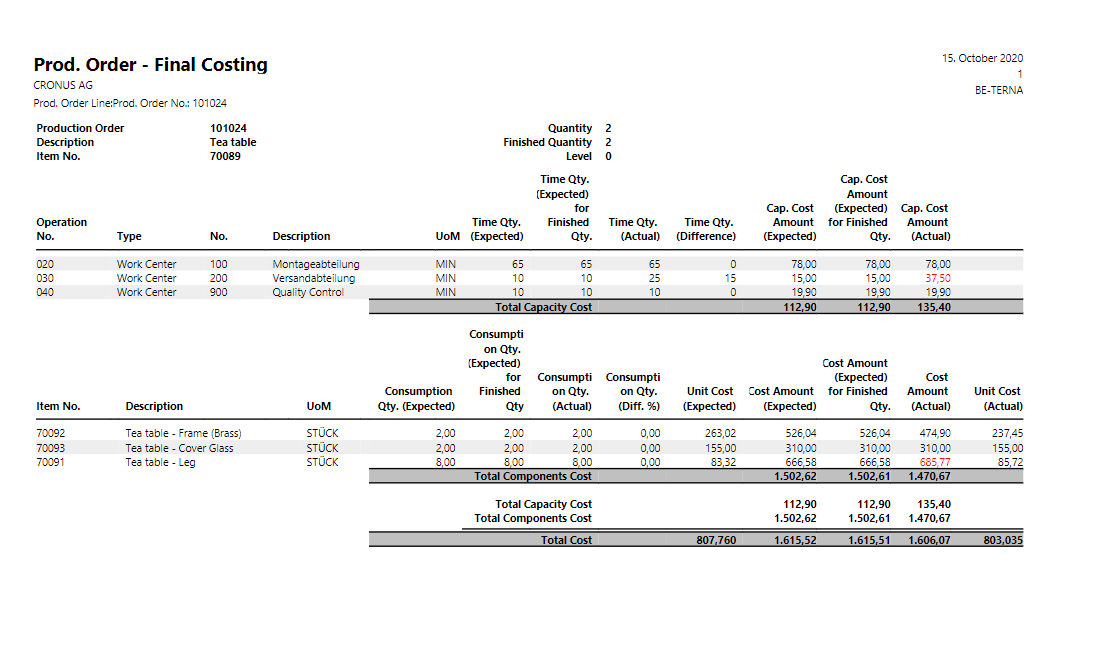

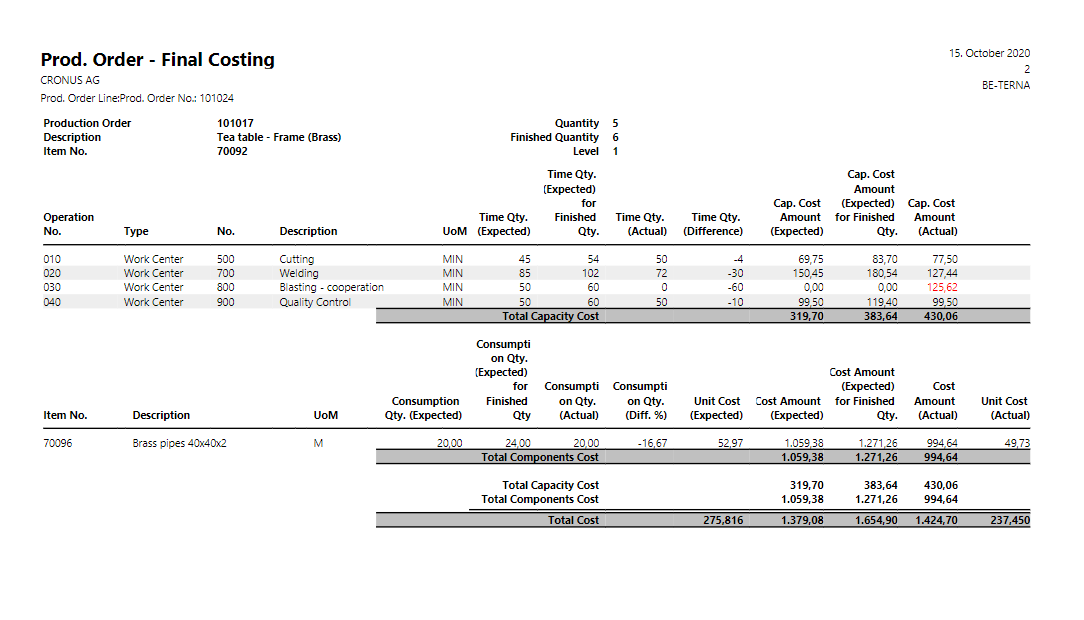

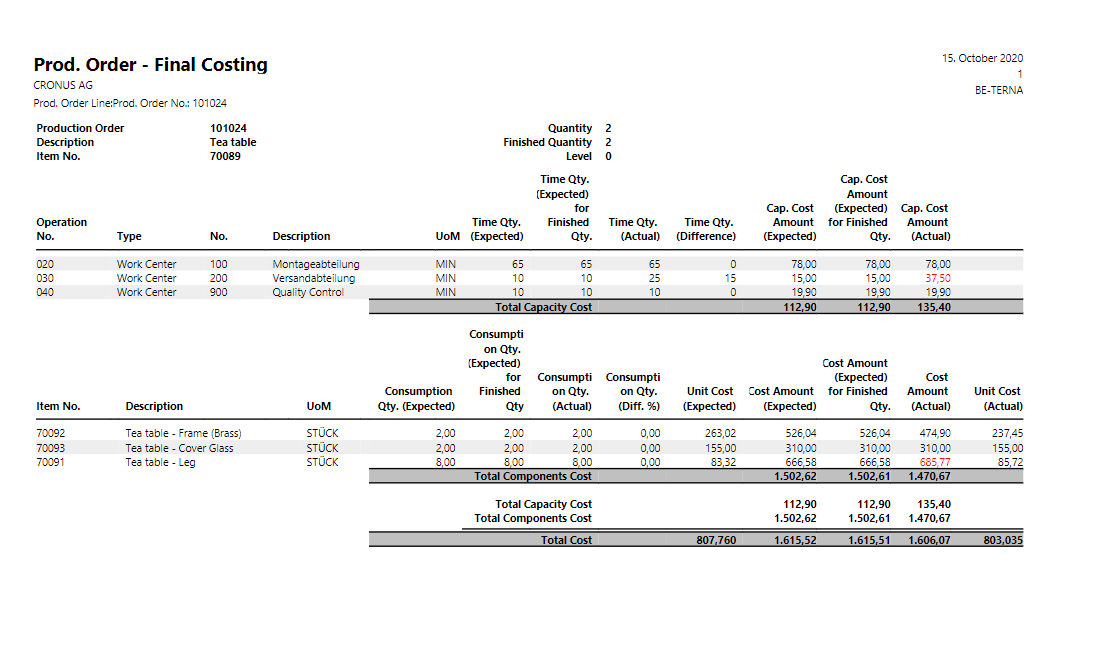

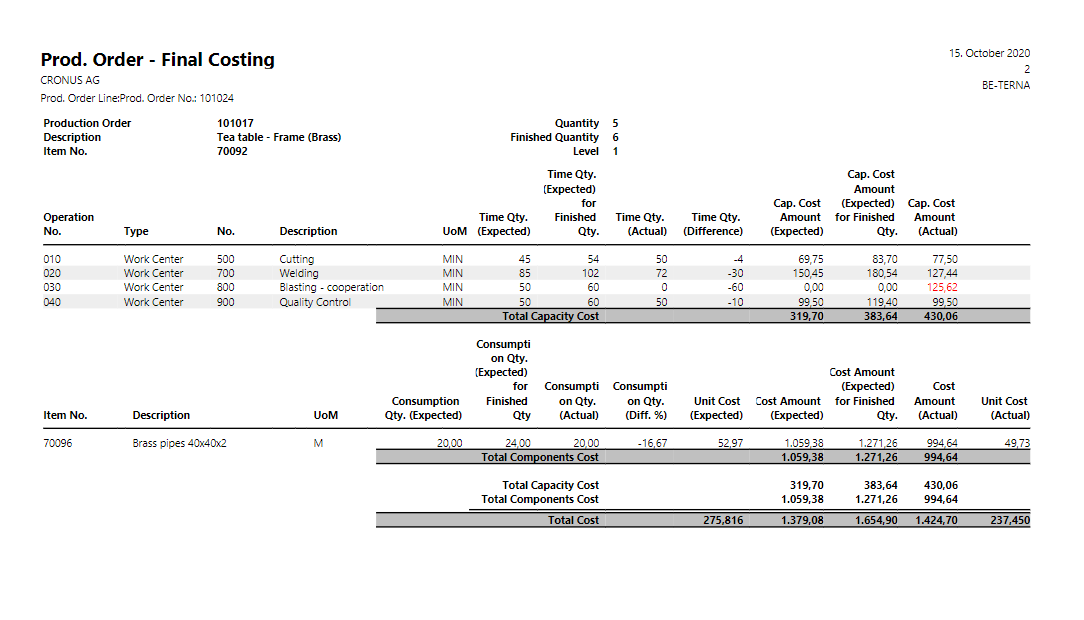

Production Order detail pages describe each production order included in production of monitored product.

Level 0 Production Order details

First Level 1 Production Order details

Production order detail print header contains following data:

- "Production Order No."

- Description from "Production Order Line"

- "Item No." from "Production Order Line"

- Quantity from "Production Order Line" = planned Quantity

- "Finished Quantity" from "Production Order Line"

- Level from Production Order hierarchy, where monitored product presents Level 0, its components (Semifinished products consumed for monitored product production) production Level 1 and so on.

Production Order Routing lines section contains following data:

- Operation No.

- "Capacity Type" from Routing Line ("Work Center" or "Machine Center")

- "Capacity No."

- Description from Routing Line

- "Unit of Measure Code" from Routing Line

- "Time Qty. (Expected)" represents "Expected Capacity Need" for complete planned capacity.

- "Time Qty. (Expected) for Finished Qty." which represents "Expected Capacity Need" multiplied by "Finished Quantity" divided by

planned Quantity ("Production Order Line".Quantity)

- "Time Qty. (Actual)" represents complete posted time for operation in production order line - for "Finished Quantity".

- "Time Qty. (Difference)" represents difference between previous two columns (for "Finished Quantity")

- "Capacity Cost Amount (Expected)" which represents "Expected Operation Cost Amount" from Routing Line (for planned Quantity)

- "Capacity Cost Amount (Expected) for Finished Quantity" which represents "Expected Operation Cost Amount" from Routing Line multiplied by "Finished Quantity" and divided by planned Quantity.

- "Capacity Cost Amount (Actual)" which represents complete Capacity cost posted for operation in Prodcution Line (for "Finished Quantity").

Production Order Component lines section contains following data:

- "Item No." from "Production Order Component Line"

- Description from "Production Order Component Line"

- "Unit of Measure Code" from "Production Order Component Line"

- "Consumption Qty. (Expected)" represents "Expected Qty." from "Production Order Component" line.

- "Consumption Qty. (Expected) for Finished Quantity" represents "Expected Qty." from "Production Order Component Line" multiplied by "Production Order Line"."Finished Quantity" divided by planned "Production Order Line".Quantity.

- "Consumption Qty. (Actual)" represents total consumed Quantity of "Item No." for "Production Order Line" (for "Finished Quantity").

- "Consumption Qty. (Diff. %)" is calculated as difference between "Consumption Qty. (Actual)" - "Consumption Qty. (Expected) for Finished Quantity" divided by "Consumption Qty. (Expected) for Finished Quantity".

- "Unit Cost (Expected)" represents "Unit Cost" from "Production Order Component" line.

- "Cost Amount (Expected)" represents "Cost Amount" from "Production Order Component" line ("Unit Cost" multiplied by "Consumption Qty. (Expected)" in "Production Order Component" line).

- "Cost Amount (Expected) for Finished Qty." is calculated as "Cost Amount (Expected)" (previous column) multiplied by "Production Order Line"."Finished Quantity" divided by "Production Order Line".Quantity.

- "Cost Amount (Actual)" represents sum of "Cost Amount (Actual)" from posted "Item Ledger Entry" consumption entries related to "Production Order Component" line.

- "Unit Cost (Actual)" is calculated as sum of "Item Ledger Entry"."Cost Amount (Actual) divided by sum of "Item Ledger Entry".Quantity for posted consumption entries.

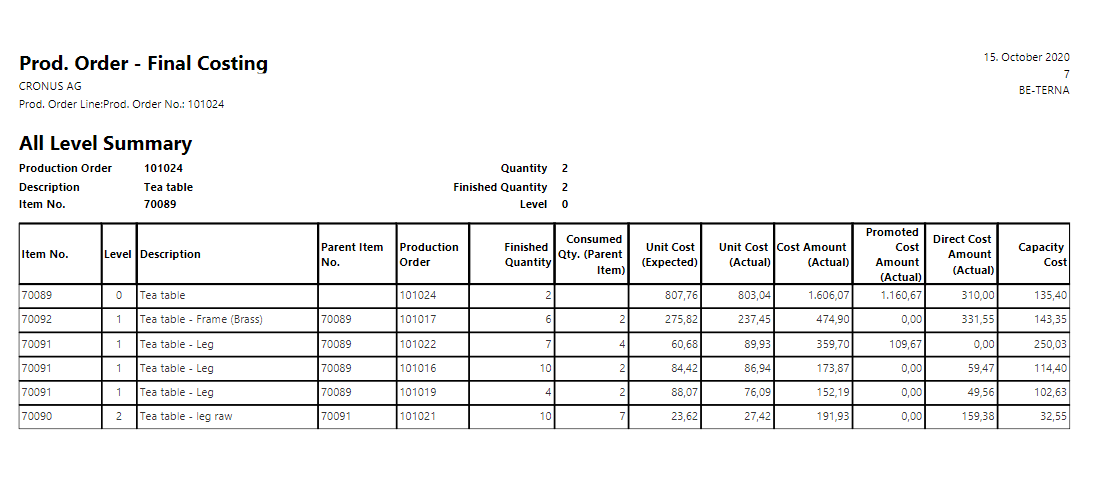

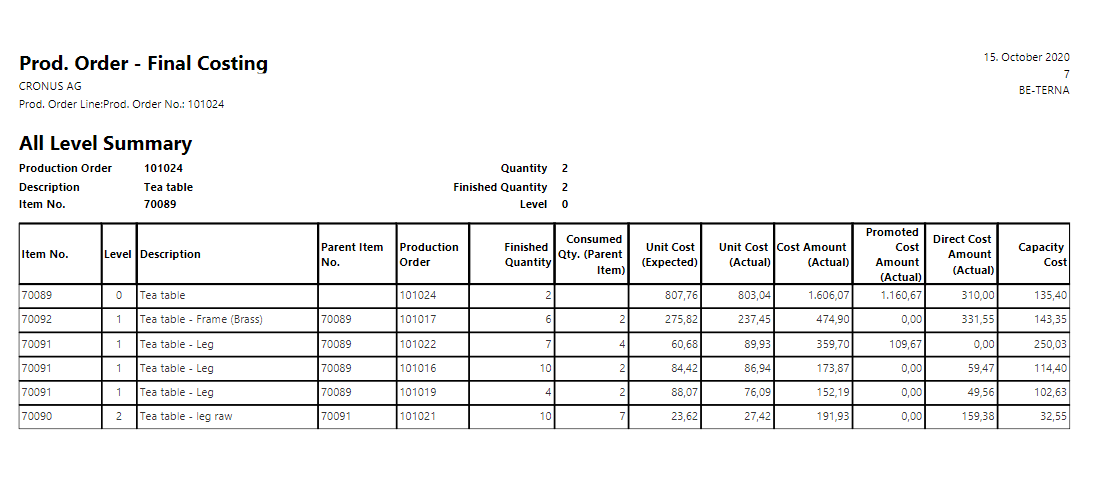

All Level Summary page contains aggregated data from all detail pages.

Data is aggregated by Production Orders and ordered by Level in production hierarchy.

Header part of page contains same data as Level 0 detail page.

Table below contains one line for each Production Order presented in previous pages.

Following columns in table are directly transferred from Production Order detail page (header part)

- "Item No."

- Level

- Description

- "Production Order"

- "Finished Quantity"

Field "Parent Item No." is presented according to production order hierarchy (into which product an item has been consumed).

Field "Consumed Qty. (Parent Item)" represents a Quantity which has been consumed to higer level product (out of "Finished Quantity"). This parameter is important to understand ratio of transferred cost from lower to higer level (Rolled-up = Promoted Cost Amount (Actual)").

Field "Unit Cost (Actual)" is transferred from a "Total Cost" aggregate in Production Order detail page for specific Production Order.

Field "Cost Amount (Actual)" is claculated as product of "Unit Cost (Actual)" and "Consumed Qty. (Parent Item)"

Field "Promoted Cost Amount (Actual)" represents sum of "Cost Amount (Actual)" of consumed semifinished products produced by lower levels Production Orders. This cost is a combination of material and capacity costs on lower levels. Next rows are explaining this amount (split to material and capacity cost).

Field "Direct Cost Amount (Actual)" represents sum of "Cost Amount (Actual)" of consumed materials which were not produced by Production orders (direct consumption on this level).

Field "Capacity Cost" represents capacity cost directly used for this prodcution order - to produce "Consumed Qty. (Parent Item)".

How to properly understand aggregates?

Field "Cost Amount (Actual)" in each line is sum of fields "Promoted Cost Amount (Actual)", "Direct Cost Amount (Actual)" and "Capacity Cost" in same line.

Sum of fields "Promoted Cost Amount (Actual)" for specific Level is sum of fields "Cost Amount (Actual)" from all lines with Level + 1.