With this function you can also use the logistical functions of the BC standard (warehouse put-aways, inventory put-aways) for subcontracting production once the external manufacturer returns the processed parts.

This means that put-aways no longer have to be posted via the delivery function of the purchase order. You thus achieve a standardized procedure both for item purchase and for the delivery of subcontracted production.

Since logistics is associated with item movements, the subcontracted operation should be the last operation in the routing. Only in this case can the put-away be set up after the warehouse receipt.

In the case of a "non-final" subcontracting operation, the warehouse receipt also posts the "received quantity" in the purchase order. However, the posted warehouse receipt is then immediately marked as "completely picked" and no warehouse put-away is created. A transport of the delivered unfinished work to the next work center must be organized manually and is not supported by the program.

In order to use the advanced features, you must configure the logistics setup on the location card as supported by BC Standard. This includes the setup of the warehouse employees for the assigned locations.

No further setup is necessary.

Warehouse receipts are set up the same way as in BC Standard. The posting of the warehouse receipts is done the same way as the warehouse receipts of item orders.

Attention:

If the operation in the production order is linked via routing link to components that are to be posted backwards, the posting may be aborted when the warehouse receipt is posted if there is not enough stock of the component. Therefore you should:

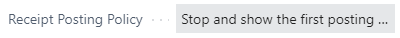

- set up the Warehouse Setup so it stops after the first posting error and the posting is aborted

- or use the function Pending consumption postings

- or use the function Pending consumption postings

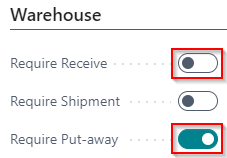

For a last subcontracting operation, BC establishes a warehouse put-away if you have activated the two-step logistics.

You can make the put-away in the same way as it is provided in BC logistics.

If you have deselected require receive in the storage location, but selected require put-away

then BC will create a inventory put-away for you if the subcontracting operation is the last operation in the routing of the production order. You can register the inventory put-away as usual.

then BC will create a inventory put-away for you if the subcontracting operation is the last operation in the routing of the production order. You can register the inventory put-away as usual.

"Non-final" subcontracting operations are not supported by inventory put-away.

Recommendation: The combination of "non-final" subcontracting operation and inventory put-away should be excluded.