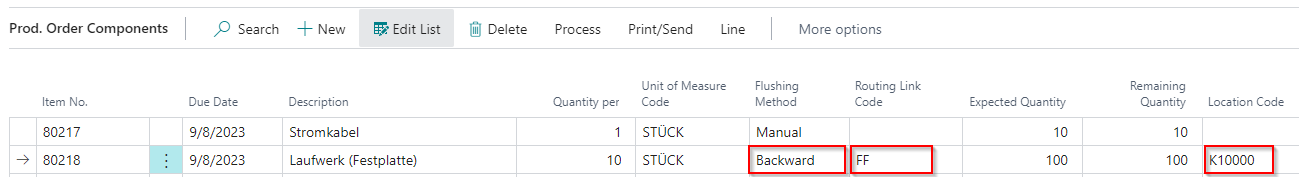

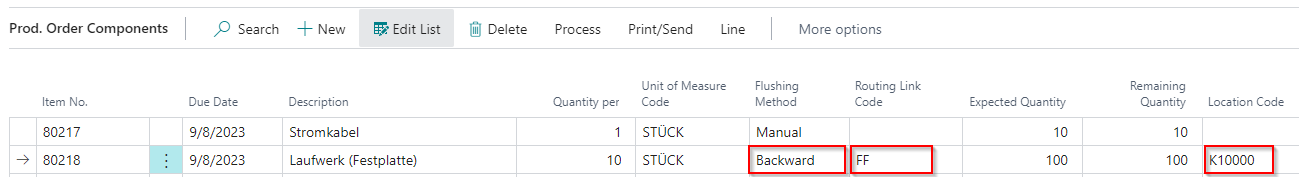

In the case of automated consumption posting in production, especially when components are linked with a Routing Link Code to an operation and with the Flushing Method Backward, transaction aborts can occur if the stock level is too low, which can hinder speedy operation. In this case the stock level would have to be corrected and the output adjusted.

The following section describes the consumption with insufficient stock.

..

..

There is now

- an output for the 2 excepted pieces

- the existing (insufficient) stock of 5 pieces from location K10000 is used up

- the pending consumption of 15 pieces is registered

Note: You can get there from the released production order through Related, Order, Consumption Pending Entries.

Note: You can get there from the released production order through Related, Order, Consumption Pending Entries.

If there is a production order with pending consumption and status = open - the production order can´t be closed - the setting in the location can´t be turned off

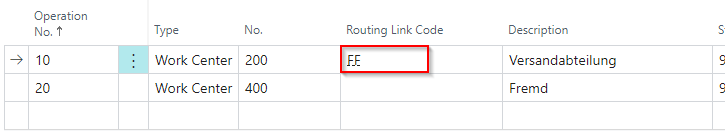

Note: The following calculations and processes are only carried out for components that are to be posted backwards due to a routing link code. Other consumption postings are not affected.

If an automatic component consumption is to be posted based on an output, before the consumption posting: - the current stock level is calculated on the location of the component row - this stock is compared with the component quantity to be posted automatically - If the current stock level is lower than the component quantity to be posted, it will calculate pending quantity = component quantity to be posted - current stock - The program registers the pending quantity in an open entry for pending consumption

| Field | Content | Description |

|---|---|---|

| Entry No. | Integer | Each pending consumption has a unique Entry. No. |

| Consumption Status | Option | The program saves entries with the following options: Pending, Posted, Canceled. The field documents the original creation of the entry: Pending - automatically generated when quantity is reduced, Posted - Registration of a subsequent booking, Canceled - Cancelation of a reduction item. |

| Item No. | Code | Item No. of the component |

| Variant Code | Code | Variant Code of the component |

| Parent Entry No. | Integer | In case of a cancellation, (Consumption Status = Canceled) the field shows the Entry. No. of the pending item that was cancelled. |

| Posting Date | Date | Date where the post was established: Pending - The posting date of consumption, Posted - Date of the subsequent consumption posting, Canceled - Cancellation date. |

| Description | Text | Description from the component line or book sheet |

| Consumption Status | Date | Date of the original consumption posting |

| Origin Qty. (Base) | Decimal | attempted quantity of the original consumption posting |

| Remaining Pending Qty. (Base) | Decimal | Pending remaining quantity of the current item |

| Origin Pending Qty. (Base) | Decimal | Original outstanding quantity of the component at the output |

| Positive | True/False | True, if the Origin Pending Qty. (Base) is greater than 0 |

| Open | True/False | True, if the Remaining Pending Qty. (Base) is not equal to 0 |

| Location Code | Code | Location to which the pending quantity refers to |

| Prod. Order No. | Code | Number of the production order |

| Prod. Order Line No. | Integer | Line number of the production order line |

| Component Line No. | Integer | Line number of the production order component that led to the pending consumption |